Preparation method of carbon-nitrogen-boron nanosheet optical antibacterial material

A technology of antibacterial materials and nanosheets, applied in the field of light antibacterial, can solve the problems of expensive and complex precious metals, achieve the effect of high surface potential, less layer accumulation, and enhanced capture ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

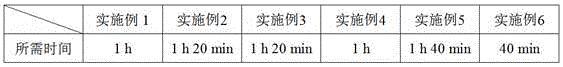

Embodiment 1

[0020] A preparation method of carbon nitrogen boron nanosheet light antibacterial material, specifically comprising the following steps:

[0021] (1) Preparation of the precursor: 0.05 g of 3-aminophenylboronic acid was added to 4 g of cyanamide solution (50%, w / w). After ultrasonic dissolution, 8 g of silica microsphere sol was added dropwise while stirring ( 40%, w / w) as a template, evaporate to dryness at 60°C, then take it out and grind it evenly;

[0022] (2) Calcination of the precursor: put the precursor prepared in step (1) in a muffle furnace, control the temperature rise rate to 4.5°C / min, raise it from room temperature to 400°C, keep it warm for 4 hours, and then cool it down naturally. Take out and grind evenly;

[0023] (3) Removal of the template: Add the homogeneously ground material in step (2) to 75mL of 4mol / L ammonium hydrogen fluoride solution, shake for 48h, centrifuge at 12000rpm for 15min, remove the supernatant, and transfer the bottom sediment to the...

Embodiment 2

[0026] A preparation method of carbon nitrogen boron nanosheet light antibacterial material, specifically comprising the following steps:

[0027] (1) Preparation of precursor: Add 1 g of boric acid to 4 g of dicyandiamide solution (50%, w / w), after ultrasonic dissolution, add 8 g of silica microsphere sol (40%, w / w) dropwise while stirring ) as a template, evaporate to dryness at 60°C, then take it out and grind it evenly;

[0028] (2) Calcination of the precursor: place the precursor prepared in step (1) in a muffle furnace, control the temperature rise rate to 4.5°C / min, raise it from room temperature to 600°C, keep it warm for 4 hours, and then cool it down naturally. Take out and grind evenly;

[0029] (3) Removal of the template: Add the homogeneously ground material in step (2) to 75mL of 4mol / L ammonium hydrogen fluoride solution, shake for 48h, centrifuge at 10,000rpm for 15min, remove the supernatant, and transfer the bottom sediment to the dialysis belt (3500Da) d...

Embodiment 3

[0032] A preparation method of carbon nitrogen boron nanosheet light antibacterial material, specifically comprising the following steps:

[0033] (1) Preparation of precursor: Add 0.01 g of 3-aminophenylboronic acid to 4 g of cyanamide solution (50%, w / w). After ultrasonic dissolution, add 8 g of alumina nanoparticles as a template while stirring, steam at 60 °C dry, then take out and grind evenly;

[0034] (2) Calcination of the precursor: put the precursor prepared in step (1) in a muffle furnace, control the temperature rise rate at 10 ℃ / min, from room temperature to 1000 ℃, keep it warm for 4 hours, and then cool it naturally. Take out and grind evenly;

[0035] (3) Removal of the template: Add the homogeneously ground material in step (2) into 100 mL of 5mol / L hydrochloric acid solution, shake for 48 hours, centrifuge at 12,000 rpm for 15 minutes, remove the supernatant, and transfer the bottom sediment to the dialysis belt (3500Da) dialysis to remove impurities; after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com