Diffluent side-chain fluorine-containing copolymerization ether glycol prepared by copolymerizing perfluoroalkyl glycidyl ether and polybasic cyclic ether

A technology of glycidyl ether and copolyether diol, which is applied in the field of soluble side chain fluorine-containing copolyether diol, can solve the problems of rising use cost, waste of effective resources, harsh solvents, etc., to reduce processing cost and expand the use space , easy to dissolve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

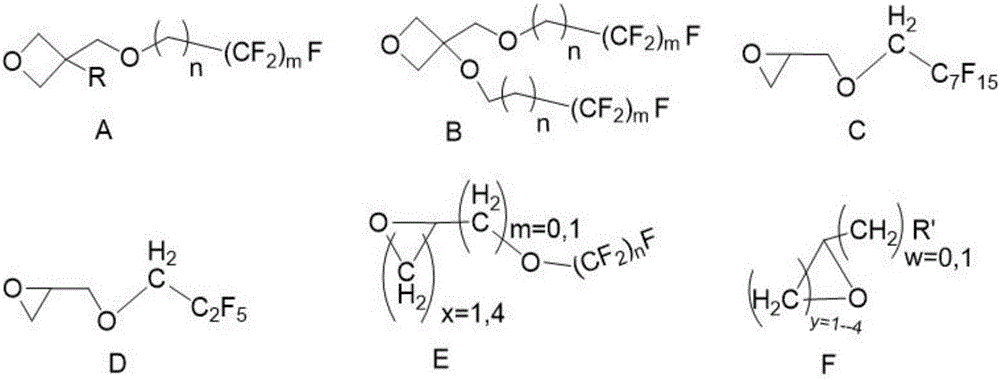

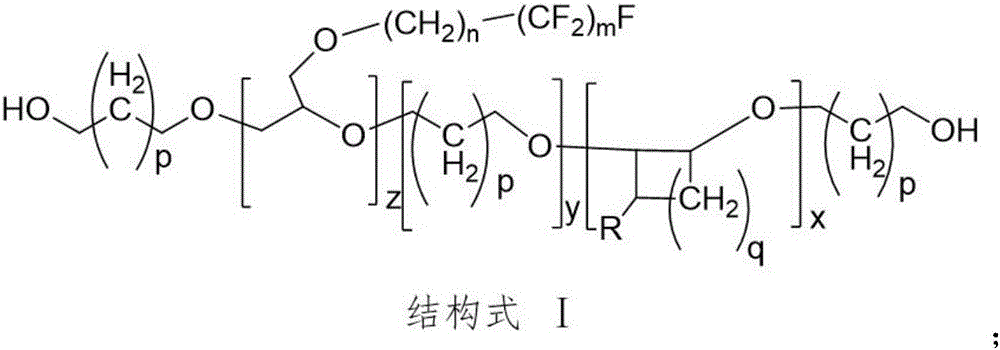

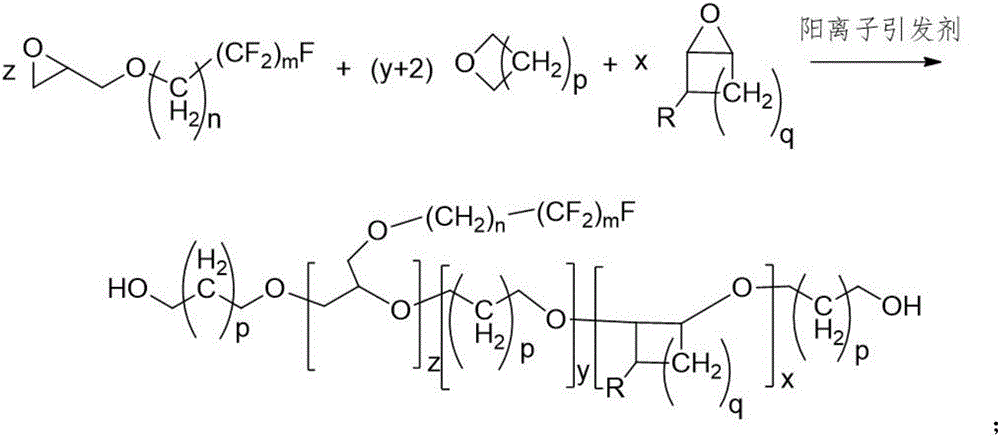

Method used

Image

Examples

Embodiment 1

[0039] Dissolve 0.05 mol of 2-(heptafluorotridecyl)ethyl glycidyl ether and 0.95 mol of 2-methylphenyl glycidyl ether in a dichloromethane solution formed with 100 mL of dichloromethane.

[0040] Then, in a 1000mL kettle, after replacing the air in the kettle with pure nitrogen, the temperature was lowered to -10°C, and 5 moles of oxetane, 50 mL of dichloromethane, 0.15 moles of 98% concentrated sulfuric acid and 0.18 moles of ethylene glycol were added. After cooling down to -10°C and stirring for 20 minutes and maintaining this temperature, add 0.05 moles of 2-(heptafluorotridecyl)ethyl glycidyl ether and 0.95 moles of 2-methylphenyl glycidyl ether dropwise. Methane solution, control dripping within 2 hours. Maintain at -10°C and react for 10 hours. Add 20ml of deionized water to terminate the reaction, distill off the solvent, and neutralize to neutral with sodium carbonate solution. Add 100 mL of deionized water to wash for 20 minutes, and let stand to separate layers. ...

Embodiment 2

[0042] Dissolve 0.1 mol of 2-(heptadecafluorooctyl) ethyl glycidyl ether and 0.5 mol of benzyl glycidyl ether in 200 mL of ether to form an ether solution.

[0043]In a 1000mL kettle equipped with a stirrer, after replacing the air in the kettle with pure nitrogen, cool down to -5°C, add 100mL of ether as a solvent, add 1.8 moles of oxetane, 0.072 moles of perchloric acid and 0.12 moles of butane diol. The above ternary ether solution formed by dissolving 0.1 mole of 2-(heptadecafluorooctyl) ethyl glycidyl ether and 0.5 mole of benzyl glycidyl ether and 200 mL of diethyl ether was added dropwise, and the controlled dropwise addition was completed within 3 hours. Keep at -5°C, react for 8 hours, add 30 mL of deionized water to terminate the reaction, distill off the solvent, and neutralize to neutral with sodium bicarbonate solution. Add 200 mL of deionized water, stir and wash with water for 20 minutes, let stand to separate layers, and wash the oil phase with distilled water...

Embodiment 3

[0045] Dissolve 0.15 moles of 1-(nonafluorobutyl) methyl glycidyl ether and 0.3 moles of benzyl glycidyl ether in 250 mL of acetone to form a three-acetone solution.

[0046] In a 1000 mL kettle equipped with a stirrer, after replacing the air in the kettle with pure nitrogen, cool down to -0°C and add 100 mL of acetone as a solvent, add 0.45 moles of tetrahydrofuran, 0.0225 moles of perchloric acid and 0.027 moles of butanediol. The acetone solution formed by dissolving 0.15 mol of 1-(nonafluorobutyl)methyl glycidyl ether and 0.3 mol of benzyl glycidyl ether in 250 mL of acetone was added dropwise, and the controlled dropwise addition was completed within 3 hours. Keep at 0°C, react for 10 hours, add 50ml of deionized water to terminate the reaction, distill off the solvent, and neutralize to neutral with ammonium carbonate aqueous solution. Add 200 mL of deionized water to wash for 20 minutes, let stand to separate, and wash the oil phase with distilled water again, let stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com