Anti-impact high-weather-resistant water-based industrial paint and preparation method thereof

An impact-resistant and weather-resistant technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as good hardness, poor toughness, and poor anti-corrosion performance, and achieve the effect of improving impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] A preparation method of the above-mentioned impact-resistant high-weather-resistant water-based industrial anticorrosion coating, comprising the following steps: adding water, polyurethane modified acrylate emulsion, water-based polyurethane dispersion, dispersant, substrate wetting and Anti-cratering additives, 0.1% to 0.2% defoaming agent, and disperse at a medium speed; then slowly add titanium dioxide, talc powder, superfine calcium carbonate, sericite powder, aluminum zinc phosphomolybdate antirust pigment, nano Silica, add water to rinse the cylinder wall, disperse at high speed for 30-40 minutes to fineness ≤ 50 microns; then add leveling agent, thickener, remaining defoamer, alkoxysilane at medium and low dispersing speed The adhesion promoter and other components are dispersed at a medium speed for 20-30 minutes to obtain the finished product; the fineness and viscosity of the finished product are tested by sampling, and the finished product is qualified when th...

Embodiment 1

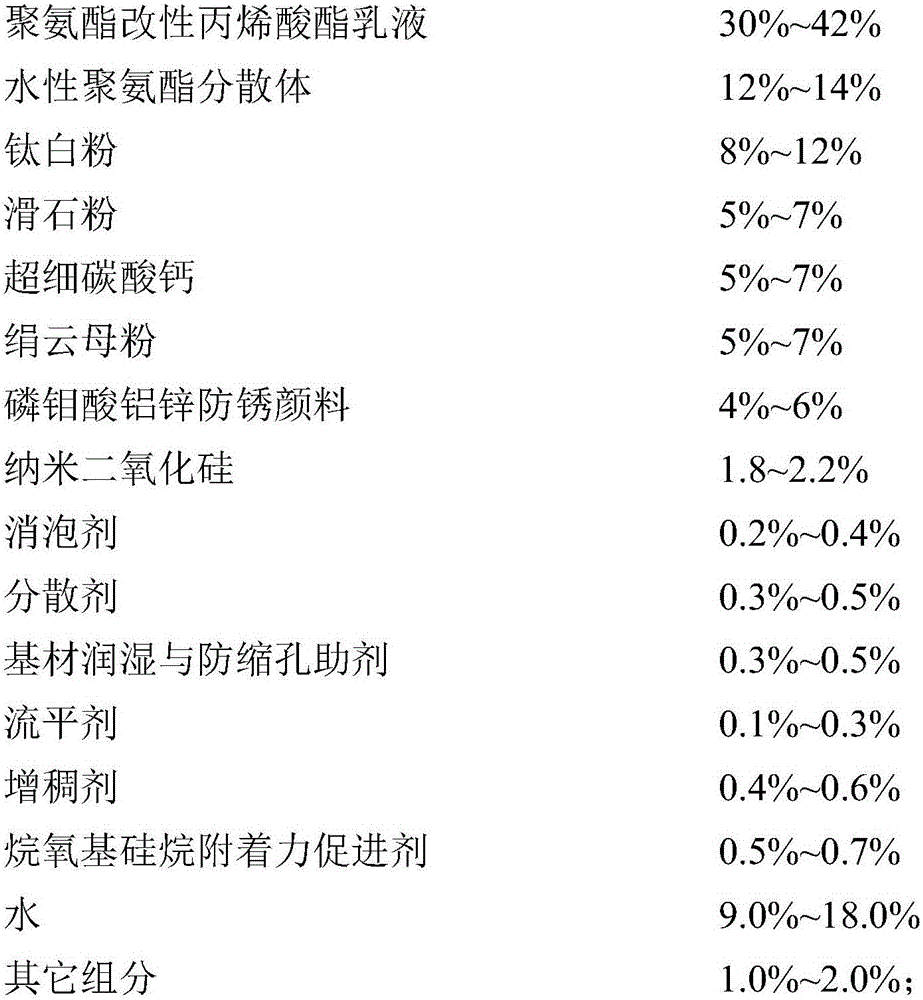

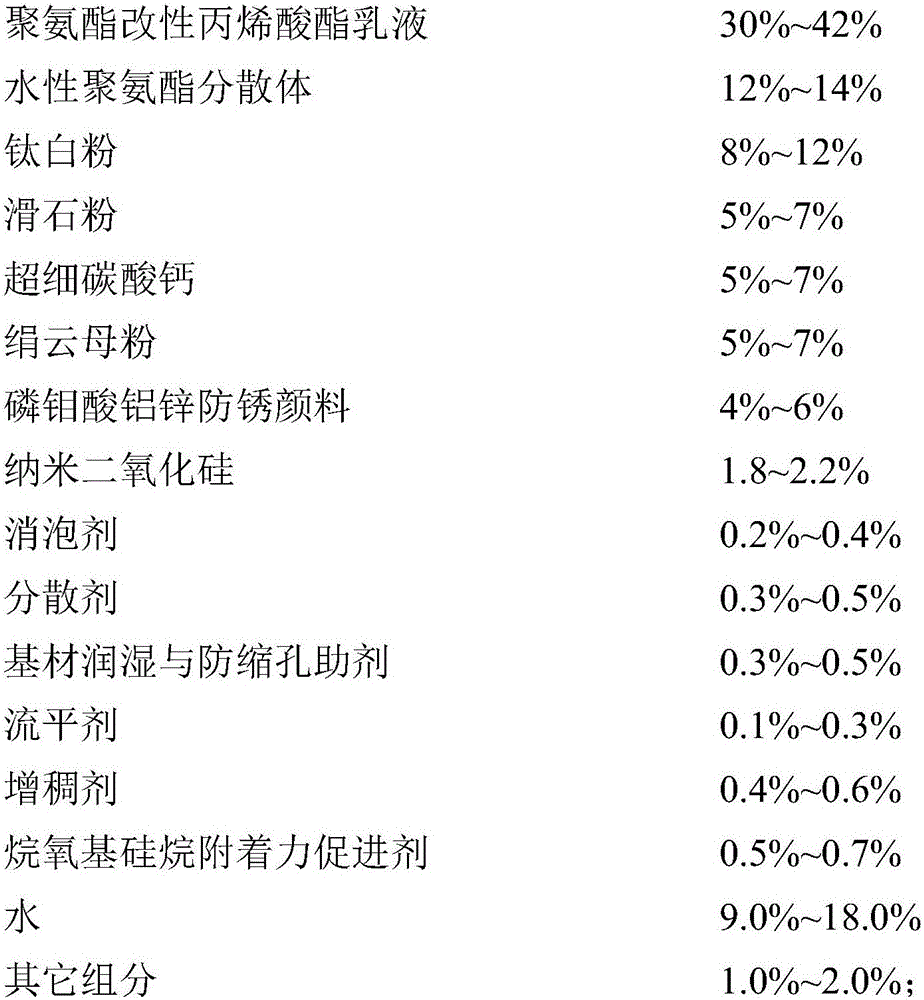

[0067] A water-based industrial anti-corrosion coating with high impact resistance and weather resistance, which consists of the following components by weight percentage:

[0068]

[0069]

[0070]The preparation method of the above-mentioned impact-resistant and high-weather-resistant water-based industrial anticorrosion coating comprises the following steps: adding water, polyurethane modified acrylate emulsion, water-based polyurethane dispersion, dispersant, substrate wetting and anti-shrinkage in a dispersion tank by weight percentage Pore aid, 0.2% defoamer, and medium-speed dispersion, the speed of the medium-speed dispersion is 600 ~ 800r / min; then slowly add titanium dioxide, talcum powder, ultrafine calcium carbonate, sericite powder, Aluminum zinc phosphomolybdate anti-rust pigment, nano silicon dioxide, add water to wash the cylinder wall, disperse at high speed for 30-40 minutes until the fineness is ≤50 microns, the speed of high-speed dispersion is 1000-...

Embodiment 2

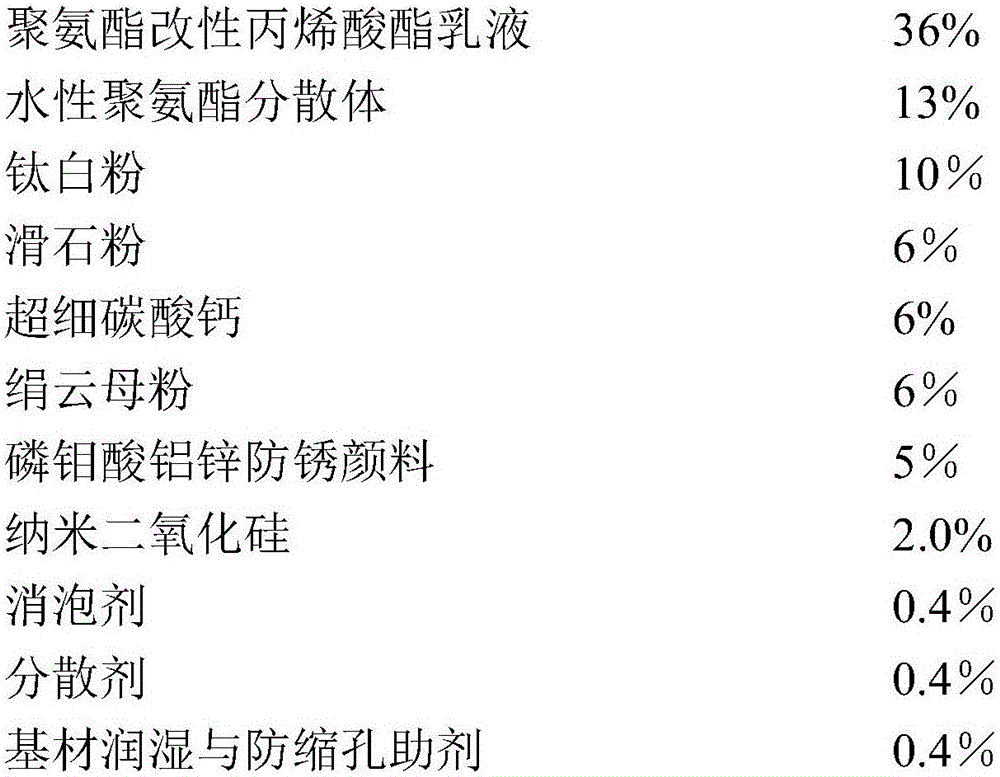

[0073] A water-based industrial anti-corrosion coating with high impact resistance and weather resistance, which consists of the following components by weight percentage:

[0074]

[0075]

[0076] The preparation method of the above-mentioned impact-resistant and high-weather-resistant water-based industrial anticorrosion coating comprises the following steps: adding water, polyurethane modified acrylate emulsion, water-based polyurethane dispersion, dispersant, substrate wetting and anti-shrinkage in a dispersion tank by weight percentage Pore aid, 0.2% defoamer, and medium-speed dispersion, the speed of the medium-speed dispersion is 600 ~ 800r / min; then slowly add titanium dioxide, talcum powder, ultrafine calcium carbonate, sericite powder, Aluminum zinc phosphomolybdate anti-rust pigment, nano silicon dioxide, add water to wash the cylinder wall, disperse at high speed for 30-40 minutes until the fineness is ≤50 microns, the speed of high-speed dispersion is 1000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com