Water-based drilling fluid suitable for long-section horizontal well of shale gas and application of water-based drilling fluid

A water-based drilling fluid and shale gas technology, applied in the field of water-based drilling fluid, can solve the problems of deep burial of continental shale, low content of brittle minerals, low maturity, etc., to change the wettability of shale, reduce the Excellent friction coefficient and rheological properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

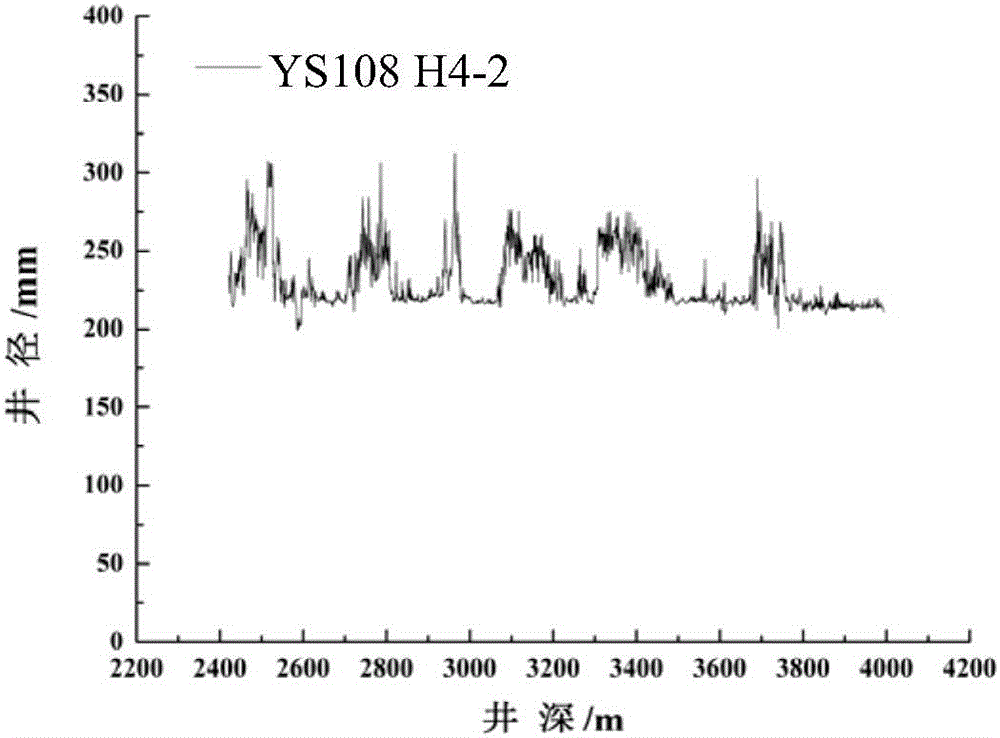

Image

Examples

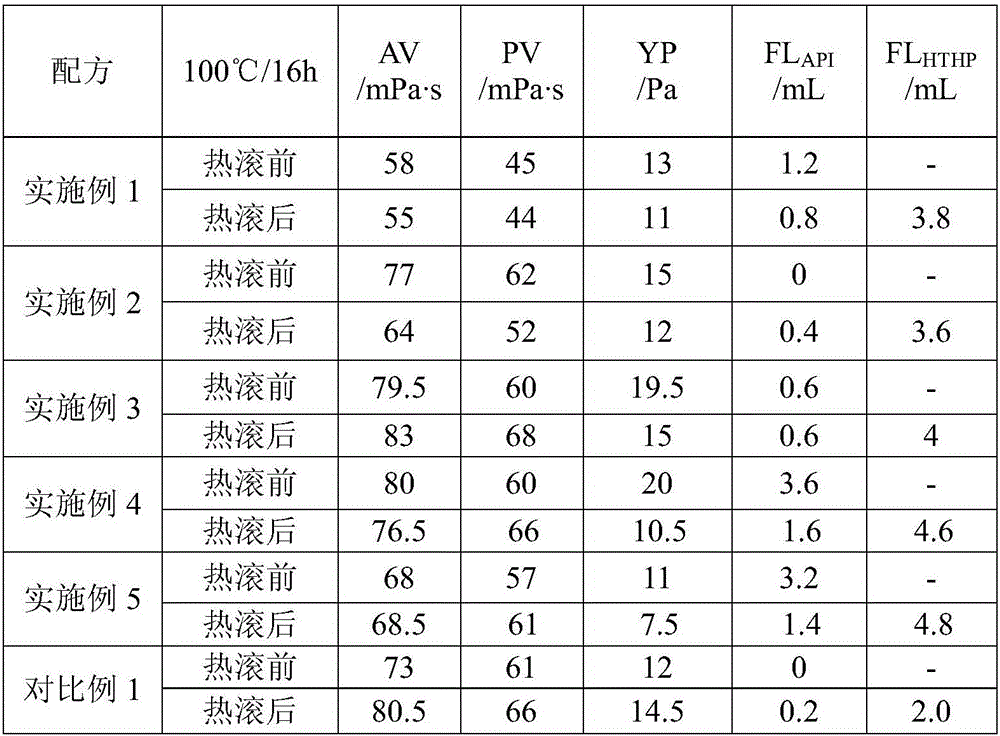

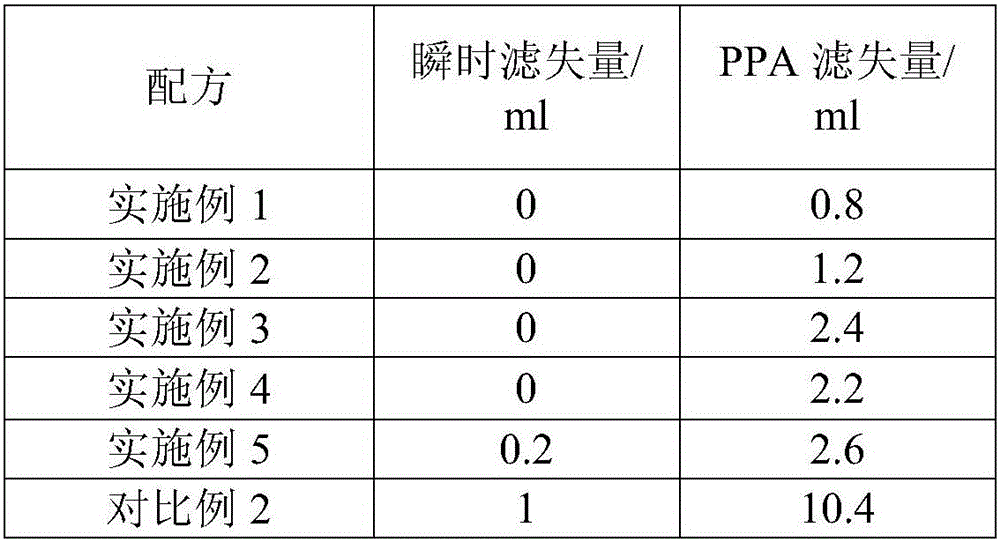

Embodiment 1

[0036] This embodiment prepares a water-based drilling fluid suitable for horizontal wells in long well sections of shale gas without adding weight. The water-based drilling fluid consists of the following components by weight: 100 parts by weight of water, 3 parts by weight of bentonite, and 0.2 parts by weight of sodium carbonate 1 part by weight of high temperature resistant modified starch, 1 part by weight of sulfonated pitch, 0.2 part by weight of low-viscosity carboxymethyl cellulose, 2 parts by weight of polyetheramine, 1 part by weight of solid graphite, 1 part by weight of anti-high temperature defoaming lubricant 1 part by weight of vinyl polymer emulsion of 20-200 nanometers, 0.5 part by weight of calcium carbonate of 800 mesh, and 1 part by weight of calcium carbonate of 1200 mesh. The above components were thoroughly mixed and stirred for 30 minutes at a high speed of 11,000 r / min to obtain the water-based drilling fluid of this example.

[0037]The anti-high tem...

Embodiment 2

[0040] The preparation density of this embodiment is 1.8g / cm 3 A water-based drilling fluid suitable for horizontal wells in long well sections of shale gas. The water-based drilling fluid consists of the following components by weight: 100 parts by weight of water, 2 parts by weight of bentonite, 0.2 parts by weight of sodium carbonate, and 3 parts by weight of potassium chloride. Parts by weight, 2 parts by weight of sulfonated pitch, 0.2 parts by weight of low-viscosity polyanionic cellulose, 0.5 parts by weight of polyoxyethylene sorbitan stearate, 2 parts by weight of potassium silicate, 1 part by weight of solid graphite, high temperature resistance 2 parts by weight of antifoaming lubricant, 2 parts by weight of vinyl polymer emulsion of 20-200 nanometers, 1 part by weight of calcium carbonate of 800 mesh, 0.5 part by weight of calcium carbonate of 1200 mesh, 0.5 part by weight of calcium carbonate of 2000 mesh, 0.1 part by weight of potassium hydroxide parts by weight,...

Embodiment 3

[0044] The preparation density of this embodiment is 2.2g / cm 3 A water-based drilling fluid suitable for horizontal wells in long well sections of shale gas. The water-based drilling fluid consists of the following components by weight: 100 parts by weight of water, 1.5 parts by weight of bentonite, 0.2 parts by weight of sodium carbonate, and 3 parts by weight of potassium chloride. Parts by weight, 2 parts by weight of lignite resin, 0.2 parts by weight of low-viscosity polyanionic cellulose, 0.5 parts by weight of sorbitol oleate, 2 parts by weight of potassium silicate, 2 parts by weight of solid graphite, 2 parts by weight of anti-high temperature defoaming lubricant , 1.5 parts by weight of vinyl polymer emulsion of 20-200 nanometers, 0.5 parts by weight of calcium carbonate of 800 mesh, 1 part by weight of calcium carbonate of 1200 mesh, 1 part by weight of calcium carbonate of 2000 mesh, 0.1 part by weight of potassium hydroxide, viscosity reducer 1 Parts by weight, 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com