Metal processing method

A metal processing, ferrous metal technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of equipment damage after long-term use, unsatisfactory cleaning performance, poor rust prevention and lubricity, etc., to enhance metal luster and improve use. Longevity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

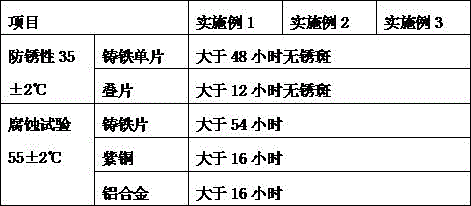

Examples

Embodiment 1

[0015] A metal processing method. When polishing ferrous metals and cutting aluminum metals, a multifunctional lubricant is used. The multifunctional lubricant needs to be heated at 70-75°C for 5 minutes 25-30 minutes before use. Then let it stand at room temperature until it starts to be used; the multifunctional and multifunctional lubricating fluid is made of the following raw materials in parts by weight: 3 parts of black cohosh extract, 3 parts of nepeta volatile oil, 4 parts of long carbon chain dibasic acid, isomer 5 parts of decanol polyoxyethylene ether, 3 parts of hydroxyoctadecadienol, 6 parts of bamboo leaf extract, 1 part of palm sorbitan, 5 parts of polyaspartic acid polymer, branched chain ISO-C13 fatty alcohol poly 3 parts of oxyethylene ether, 2 parts of sodium α-olefin sulfonate, 45 parts of deionized water;

[0016] Among them, the deionized water has a pH value of 7.5, a chloride ion content of 40 ppm, and a conductivity of 60 ms / cm.

[0017] Wherein, the ...

Embodiment 2

[0025] A metal processing method. When polishing ferrous metals and cutting aluminum metals, a multifunctional lubricant is used. The multifunctional lubricant needs to be heated at 70-75°C for 5 minutes 25-30 minutes before use. Then let it stand at room temperature until it starts to be used; the multifunctional and multifunctional lubricating liquid is made of the following raw materials in parts by weight: 6 parts of black cohosh extract, 1 part of nepeta volatile oil, 7 parts of long carbon chain dibasic acid, isomer 2 parts of decanol polyoxyethylene ether, 6 parts of hydroxyoctadecadienol, 4 parts of bamboo leaf extract, 2 parts of palm sorbitan, 5 parts of polyaspartic acid polymer, branched chain ISO-C13 fatty alcohol poly 3 parts of oxyethylene ether, 2 parts of sodium α-olefin sulfonate, 50 parts of deionized water;

[0026] Among them, the deionized water has a pH value of 7.5, a chloride ion content of 28 ppm, and a conductivity of 60 ms / cm.

[0027] The preparat...

Embodiment 3

[0030] A metal processing method. When polishing ferrous metals and cutting aluminum metals, a multifunctional lubricant is used. The multifunctional lubricant needs to be heated at 70-75°C for 5 minutes 25-30 minutes before use. Then let it stand at room temperature until it starts to be used; the multifunctional and multifunctional lubricating liquid is made of the following raw materials in parts by weight: 4 parts of black cohosh extract, 2 parts of nepeta volatile oil, 6 parts of long carbon chain dibasic acid, isomer 4 parts of decyl alcohol polyoxyethylene ether, 5 parts of hydroxyoctadecadienol, 5 parts of light bamboo leaf extract, 2 parts of palm sorbitan, 4 parts of polyaspartic acid polymer, branched chain ISO-C13 fatty alcohol poly 3 parts of oxyethylene ether, 2 parts of sodium α-olefin sulfonate, 48 parts of deionized water;

[0031] Among them, the deionized water has a pH value of 7.5-8, a chloride ion content of 25-40 ppm, and a conductivity of 60 ms / cm.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com