Industrial production and fermentation technology of pyruvic acid

A fermentation process, pyruvate technology, applied in the direction of fermentation, microorganisms, fungi, etc., can solve the problems of low yield, different range of process control points, long fermentation cycle, etc., achieve high yield, ensure product quality, quality and The effect of process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

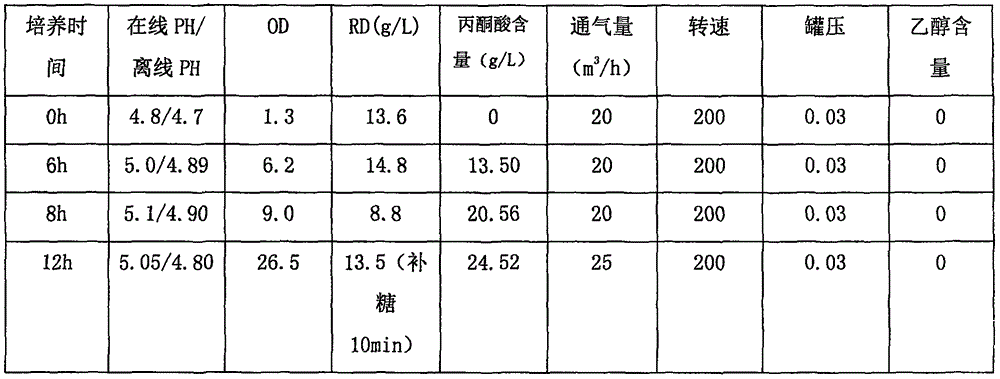

Embodiment 1

[0050] Pyruvate industrial mass production fermentation process, the specific process steps are as follows:

[0051] (1) Plate culture:

[0052] A. Plate medium (g / L): Glucose syrup 3, soybean peptone 3, beef extract peptone agar 3, calcium carbonate 0.5, dissolved in raw water, natural pH, sterilized at 121°C for 15 minutes for use;

[0053] B. Torulopsis glabrata was cultured in the plate culture medium at 30°C in an inverted culture dish for 20 hours;

[0054] (2) Eggplant bottle culture:

[0055] a. Eggplant bottle medium (g / L): glucose syrup 13, soybean peptone 11, beef extract peptone agar 10, calcium carbonate 2, ammonium chloride 0.3, dissolved in raw water, natural pH, sterilized at 121°C for 15 minutes for use;

[0056] b. Strictly follow the aseptic operation in the sterile room, pick a single colony from the preservation plate and spread it on the solid medium of the eggplant bottle;

[0057] c. Culture conditions: 30°C, after 20 hours of culture;

[0058] d. S...

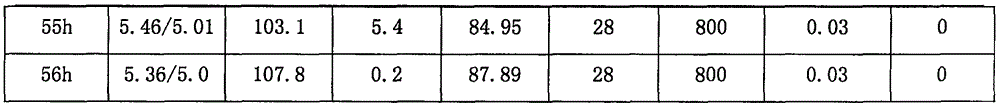

Embodiment 2

[0078] The eggplant bottles stored at 1°C in the refrigerator were used for shake flask inoculation. Shake flask medium (g / L): glucose syrup 17.5, soybean peptone 14.5, calcium carbonate 3.0, ammonium chloride 0.55, magnesium chloride 0.38, dipotassium hydrogen phosphate 0.28, Dissolve the raw water and adjust the initial pH of the medium to 5.5 with HCL at a concentration of 1.5mol / L, and sterilize at 121°C for 15 minutes for later use;

[0079] II. 20 to 30 3000ml or 5000ml triangular flasks or steel cylinders. Use a sterilized inoculation shovel in the sterile room to scoop out the bacteria from the cultured eggplant bottles and transfer them to 500ml triangular flasks or steel cylinders; The inoculum volume is 600ml / bottle or 1000ml / bottle; the cultivation temperature is 30℃, and the cultivation time is 24h;

[0080] Primary seed culture:

[0081] ① Primary seed medium (g / L): Glucose syrup 21, soybean peptone 17.5, calcium carbonate 6.8, ammonium chloride 1.8, magnesium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com