Method for accelerating enzymolysis saccharifying of lignocellulose by utilizing sludge protein as enzymolysis accessory ingredient

A technology of lignocellulase and lignocellulose, which is applied in the field of lignocellulose enzymatic hydrolysis and saccharification, can solve the problems of no research on enzymatic hydrolysis aids, increased input costs, and no significant increase in cellulase activity, so as to solve the energy crisis , save consumption, realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

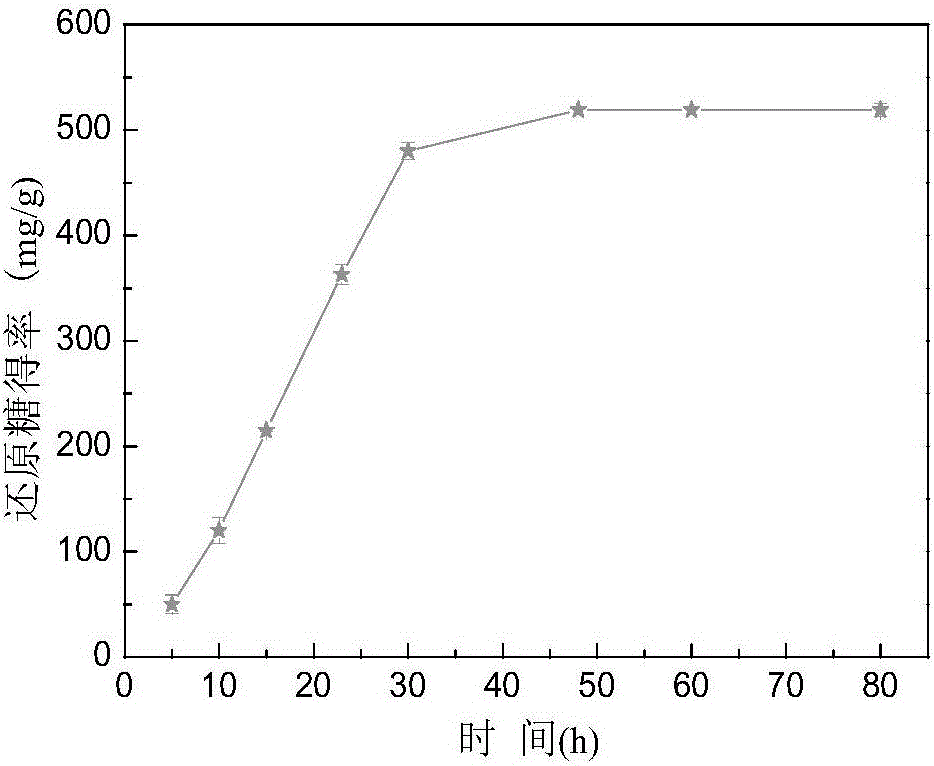

Embodiment 1

[0036] (1) Sampling of municipal sludge and biomass:

[0037] The municipal sludge is taken from the urban sewage treatment plant to remove the excessively bulky impurities in the sludge; the lignocellulosic biomass is selected from hybrid poplar sawdust, first take a certain amount of hybrid poplar sawdust, pick out the foreign matter, and the selected hybrid poplar sawdust Crush and sieve (40 mesh), soak the sifted sawdust powder in deionized water for 1 hour.

[0038] (2) Preparation of sludge protein:

[0039] Adjust the pH of the selected urban sludge to 9 with calcium oxide, take 300 mL of the adjusted pH sludge and place it in a 1 L reactor, and react for 20 minutes under the action of ultrasonic waves (108 W, 20.024 kHz). Then the reactant was cooled to room temperature, and centrifuged at 3000r / min for 10min. The supernatant was taken out and dried at 25°C for 5 days to obtain sludge protein powder, which was sealed in a polyethylene bag and stored at 4°C for later ...

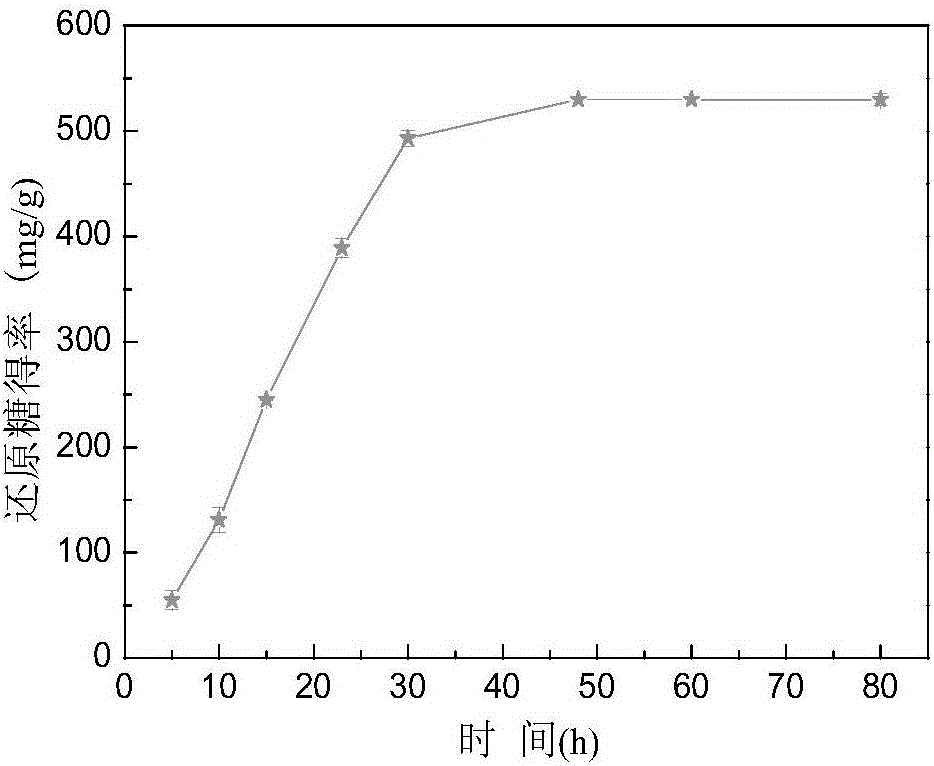

Embodiment 2

[0046] (1) Sampling of municipal sludge and biomass:

[0047] The municipal sludge is taken from the urban sewage treatment plant to remove the excessively bulky impurities in the sludge; the lignocellulosic biomass is selected from hybrid poplar sawdust, first take a certain amount of hybrid poplar sawdust, pick out the foreign matter, and the selected hybrid poplar sawdust Crush and sieve (50 mesh), soak the sifted sawdust powder in deionized water for 2 hours.

[0048] (2) Preparation of sludge protein:

[0049] Adjust the pH of the selected urban sludge to 10.5 with calcium oxide, take 350mL of the adjusted pH sludge and place it in a 1L reactor, and react under the action of ultrasonic waves (108W, 20.024kHz) for 25min. Then the reactant was cooled to room temperature, and centrifuged at 3000r / min for 11min. The supernatant was taken out and dried at 30°C for 5 days to obtain sludge protein powder, which was sealed in a polyethylene bag and stored at 4°C for later use. ...

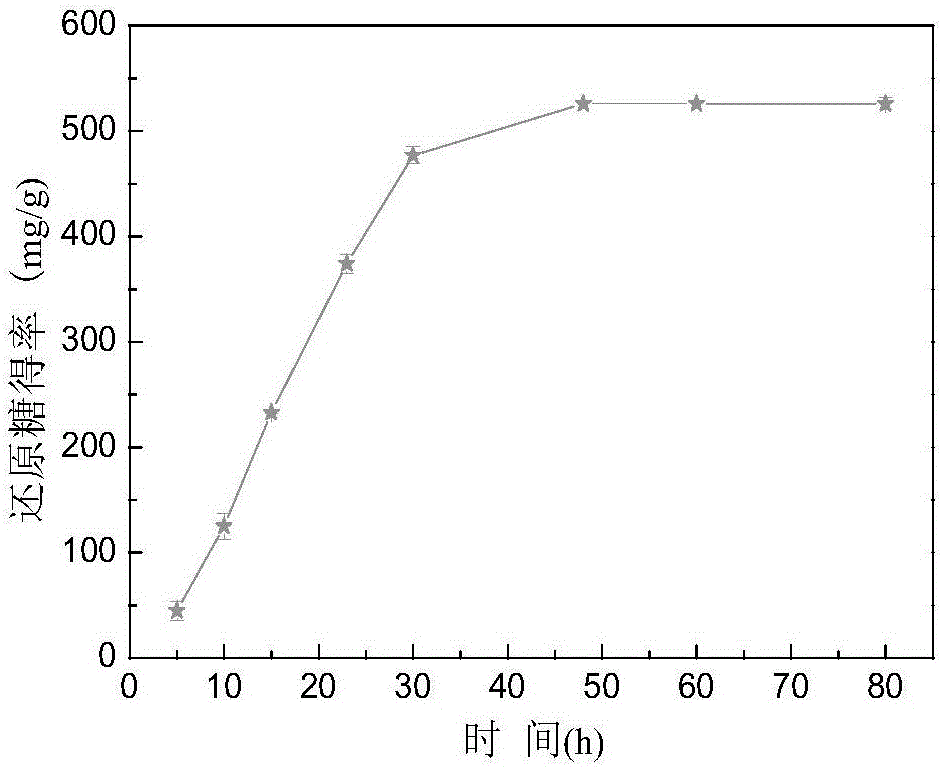

Embodiment 3

[0056] (1) Sampling of municipal sludge and biomass:

[0057] The municipal sludge is taken from the urban sewage treatment plant to remove the excessively bulky impurities in the sludge; the lignocellulosic biomass is selected from hybrid poplar sawdust, first take a certain amount of hybrid poplar sawdust, pick out the foreign matter, and the selected hybrid poplar sawdust Crush and sieve (60 mesh), soak the sifted sawdust powder in deionized water for 2.5 hours.

[0058] (2) Preparation of sludge protein:

[0059] Adjust the pH of the selected urban sludge to 11 with calcium oxide, take 400 mL of the adjusted pH sludge and place it in a 1 L reactor, and react for 30 minutes under the action of ultrasonic waves (108 W, 20.024 kHz). Then the reactant was cooled to room temperature, and centrifuged at 3000r / min for 12min. The supernatant was taken out and dried at 35°C for 5 days to obtain sludge protein powder, which was sealed in a polyethylene bag and stored at 4°C for la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com