Method for preparing multilayer thin film and evaluating binding performance thereof

A multi-layer thin film and bonding layer technology, applied in the field of membrane materials, can solve the problems that the binary coating cannot fully meet the needs of use and market demand, achieve optimized performance, improve high temperature resistance and friction resistance, and the principle is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

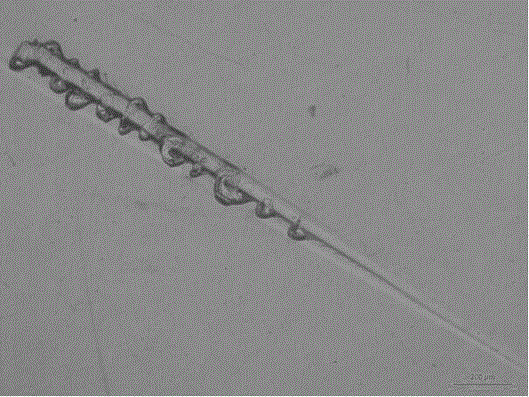

Examples

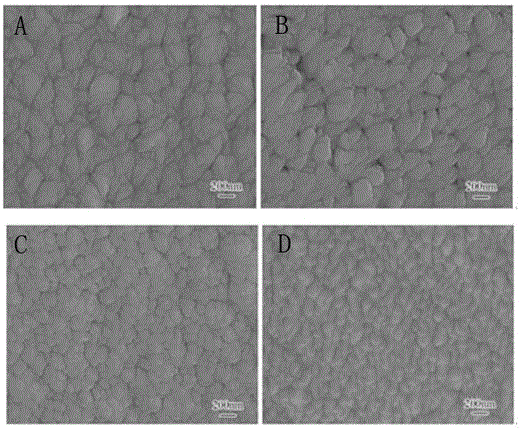

Embodiment 1

[0034] Step (1) Turn on the Teer-UDP650 / 4 type closed-field unbalanced sputtering ion plating equipment to preheat, cool and pass water, turn on the mechanical pump and molecular pump successively, and evacuate to 1.0×10 -4 Pa;

[0035] Step (2) Introduce argon gas, adjust the gas cylinder valve and flow meter, adjust the gas in the vacuum chamber, and make the magnetron target discharge glow;

[0036] Step (3) Plasma cleaning of the substrate surface: adjust the bias voltage of the substrate to -450V, bombard the substrate surface with Ar ions, remove impurities on the substrate surface, and clean for 20 minutes;

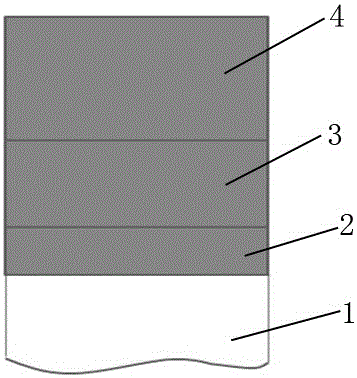

[0037] Step (4) Adjust the substrate bias to -100V, turn on two Cr targets at the same time, set the target current to 4A, deposit a layer of pure metal Cr as a base layer, and deposit for 360s.

[0038] Step (5) Adjust the bias voltage of the substrate to -75V, pass in nitrogen gas, deposit the CrN transition layer, control the flow of nitrogen gas through the OE...

Embodiment 2

[0044] Step (1) Turn on the Teer-UDP650 / 4 type closed-field unbalanced sputtering ion plating equipment to preheat, cool and pass water, turn on the mechanical pump and molecular pump successively, and evacuate to 1.0×10 -4 Pa;

[0045] Step (2) Introduce argon gas, adjust the gas cylinder valve and flow meter, adjust the gas in the vacuum chamber, and make the magnetron target discharge glow;

[0046] Step (3) Plasma cleaning of the substrate surface: adjust the bias voltage of the substrate to -450V, bombard the substrate surface with Ar ions, remove impurities on the substrate surface, and clean for 20 minutes;

[0047] Step (4) Adjust the substrate bias to -100V, turn on two Cr targets at the same time, set the target current to 4A, deposit a layer of pure metal Cr as a base layer, and deposit for 360s.

[0048]Step (5) Adjust the bias voltage of the substrate to -75V, pass in nitrogen gas, deposit the CrN transition layer, control the flow of nitrogen gas through the OEM...

Embodiment 3

[0053] Step (1) Turn on the Teer-UDP650 / 4 type closed-field unbalanced sputtering ion plating equipment to preheat, cool and pass water, turn on the mechanical pump and molecular pump successively, and evacuate to 1.0×10 -4 Pa;

[0054] Step (2) Introduce argon gas, adjust the gas cylinder valve and flow meter, adjust the gas in the vacuum chamber, and make the magnetron target discharge glow;

[0055] Step (3) Plasma cleaning of the substrate surface: adjust the bias voltage of the substrate to -450V, bombard the substrate surface with Ar ions, remove impurities on the substrate surface, and clean for 20 minutes;

[0056] Step (4) Adjust the substrate bias to -100V, turn on two Cr targets at the same time, set the target current to 4A, deposit a layer of pure metal Cr as a base layer, and deposit for 360s.

[0057] Step (5) Adjust the bias voltage of the substrate to -75V, pass in nitrogen gas, deposit the CrN transition layer, control the flow of nitrogen gas through the OE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com