A kind of titanium-magnesium alloy anodic oxidation coloring method

A titanium-magnesium alloy, anodic oxidation technology, applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of weak bonding between anodic oxide film and substrate surface oxide film, high surface energy of anodic oxide film, and anodic oxidation. Poor film compactness and other problems, to achieve good practical application prospects, obvious degreasing effect, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

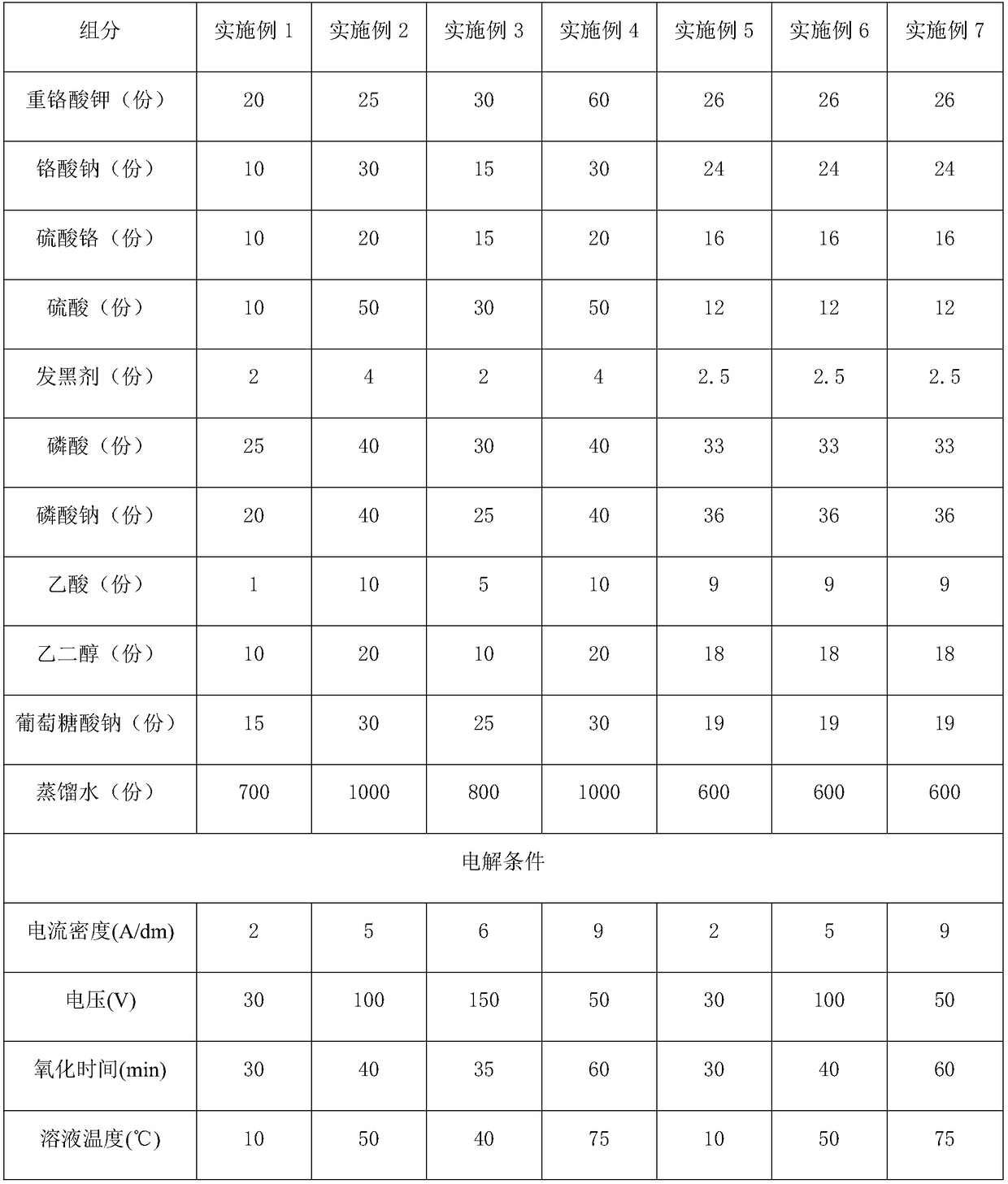

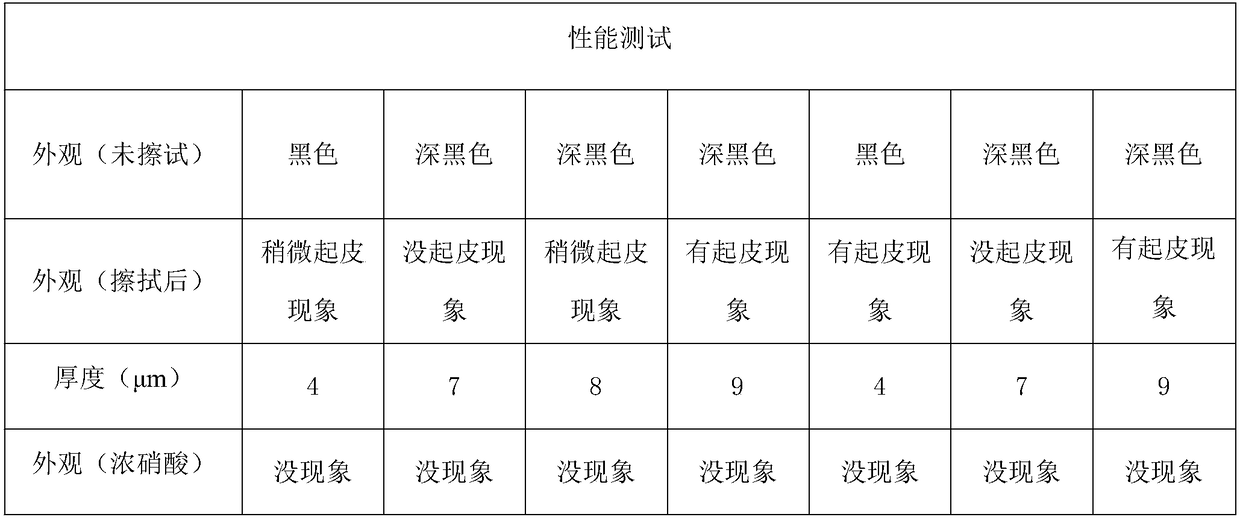

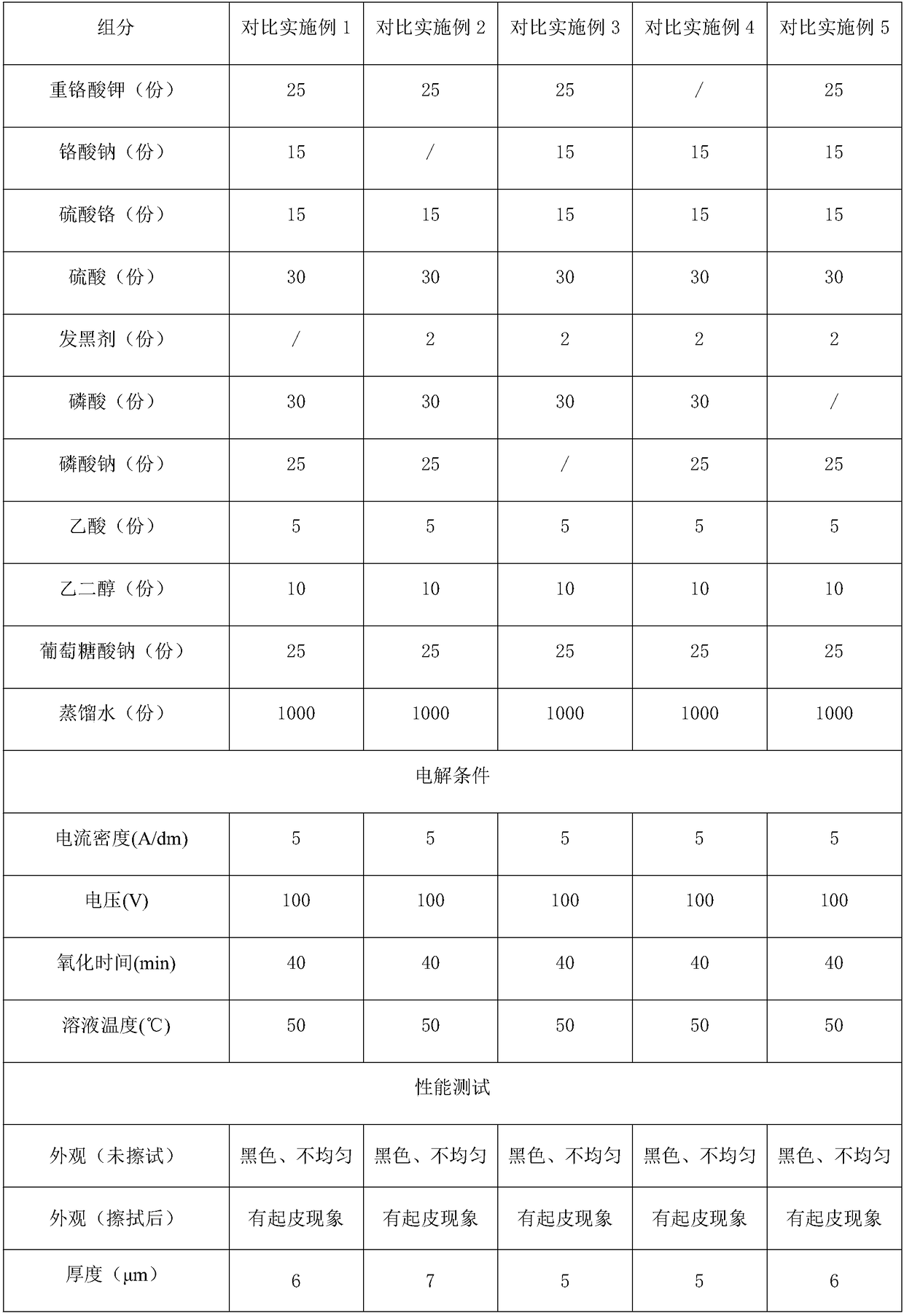

Embodiment 1

[0028] A kind of titanium-magnesium alloy anodic oxidation coloring method, comprises the steps:

[0029] (1) Pretreatment: sequentially carry out chemical degreasing, primary water washing, pickling, and secondary water washing process steps on the titanium-magnesium alloy sample to obtain titanium-magnesium alloy sample A;

[0030] (2) Anodizing: calculated in parts by weight, 20 parts of potassium dichromate, 10 parts of sodium chromate, 10 parts of chromium sulfate, 10 parts of sulfuric acid, 2 parts of blackening agent, 25 parts of phosphoric acid, 20 parts of sodium phosphate, 1 part of acetic acid, 10 parts of ethylene glycol, 15 parts of sodium gluconate and 700 parts of distilled water are mixed and prepared into a titanium-magnesium alloy anodizing solution, with the titanium-magnesium alloy sample A as a working electrode, and a graphite electrode as an auxiliary electrode. The working electrode and the auxiliary electrode are completely immersed in the titanium-mag...

Embodiment 2

[0033] (1) Pretreatment: sequentially carry out chemical degreasing, primary water washing, pickling, and secondary water washing process steps on the titanium-magnesium alloy sample to obtain titanium-magnesium alloy sample A;

[0034](2) Anodizing: calculated in parts by weight, 25 parts of potassium dichromate, 15 parts of sodium chromate, 15 parts of chromium sulfate, 30 parts of sulfuric acid, 2 parts of blackening agent, 30 parts of phosphoric acid, 25 parts of sodium phosphate, 5 parts of acetic acid, 10 parts of ethylene glycol, 25 parts of sodium gluconate and 1000 parts of distilled water are mixed and prepared into a titanium-magnesium alloy anodizing solution, with the titanium-magnesium alloy sample A as a working electrode, and a graphite electrode as an auxiliary electrode. The working electrode and the auxiliary electrode are completely immersed in the titanium-magnesium alloy anodizing solution for anodic oxidation, and the current density is 5A / dm 2 , the vol...

Embodiment 3

[0037] (1) Pretreatment: sequentially carry out chemical degreasing, primary water washing, pickling, and secondary water washing process steps on the titanium-magnesium alloy sample to obtain titanium-magnesium alloy sample A;

[0038] (2) Anodizing: calculated in parts by weight, 30 parts of potassium dichromate, 20 parts of sodium chromate, 13 parts of chromium sulfate, 20 parts of sulfuric acid, 3 parts of blackening agent, 35 parts of phosphoric acid, 30 parts of sodium phosphate, 8 parts of acetic acid, 15 parts of ethylene glycol, 20 parts of sodium gluconate and 800 parts of distilled water are mixed and prepared into a titanium-magnesium alloy anodizing solution, with the titanium-magnesium alloy sample A as a working electrode, and a graphite electrode as an auxiliary electrode. The working electrode and the auxiliary electrode are completely immersed in the titanium-magnesium alloy anodizing solution for anodic oxidation, and the current density is 6A / dm 2 , the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com