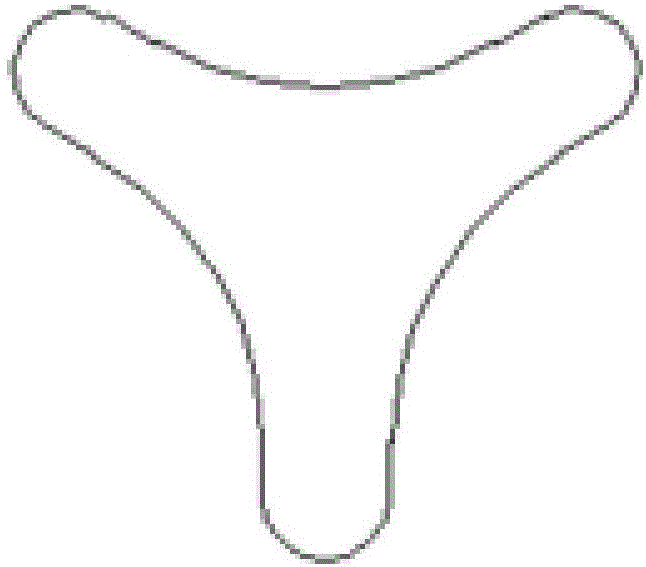

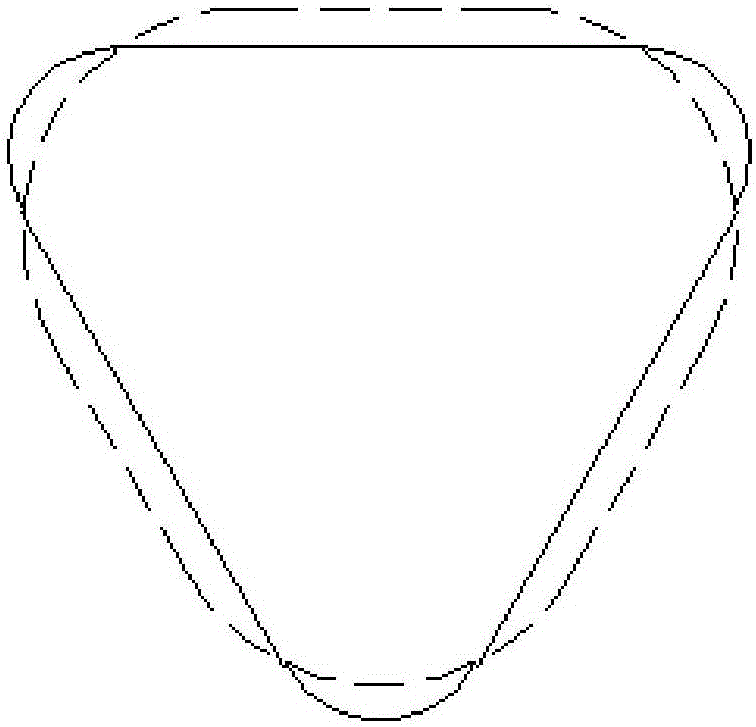

Triangular profiled polyester fiber HOY filament and preparation method thereof

A polyester fiber and special-shaped technology, applied in the field of polyester fiber, can solve the problems of poor product shape retention, weakening extrusion expansion ratio, reducing export expansion, etc., achieving good shape retention effect and reducing extrusion expansion. ratio, the effect of reducing export expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A preparation method of triangular shaped polyester fiber HOY yarn. The spinning melt is measured, extruded, cooled, oiled and wound to obtain polyester fiber HOY yarn;

[0041] Firstly, a spinning melt is prepared. The monomers of terephthalic acid and ethylene glycol are prepared into a slurry, wherein the molar ratio of terephthalic acid and ethylene glycol is 1:1.2, and then the catalyst, stabilizer and saturated fatty acid are added. After the metal salt is uniformly mixed, the esterification reaction is carried out. The esterification reaction is pressurized in a nitrogen atmosphere. The pressurization pressure is normal pressure. The temperature of the esterification reaction is 250°C. When the amount of water distilled in the esterification reaction reaches the theoretical level 90% of the value is the end point of the esterification reaction; then after the end of the esterification reaction, the polycondensation reaction in the low vacuum stage starts under negati...

Embodiment 2

[0055] A preparation method of triangular shaped polyester fiber HOY yarn. The spinning melt is measured, extruded, cooled, oiled and wound to obtain polyester fiber HOY yarn;

[0056] Firstly, a spinning melt is prepared. The monomers of terephthalic acid and ethylene glycol are prepared into a slurry, wherein the molar ratio of terephthalic acid and ethylene glycol is 1:2.0, and then the catalyst, stabilizer and saturated fatty acid are added. After the metal salt is evenly mixed, the esterification reaction is carried out. The esterification reaction is pressurized in a nitrogen atmosphere, the pressure is 0.3MPa, and the temperature of the esterification reaction is 260°C. When the amount of water distilled in the esterification reaction reaches the theoretical level 90% of the value is the end point of the esterification reaction; then after the end of the esterification reaction, the polycondensation reaction in the low vacuum stage starts under negative pressure. The pressu...

Embodiment 3

[0069] A preparation method of triangular shaped polyester fiber HOY yarn. The spinning melt is measured, extruded, cooled, oiled and wound to obtain polyester fiber HOY yarn;

[0070] Firstly, a spinning melt is prepared. The monomers of terephthalic acid and ethylene glycol are prepared into a slurry, wherein the molar ratio of terephthalic acid and ethylene glycol is 1:1.6, and then the catalyst, stabilizer and saturated fatty acid are added. After the metal salt is evenly mixed, the esterification reaction is carried out. The esterification reaction is pressurized in a nitrogen atmosphere. The pressure is 0.2MPa, and the temperature of the esterification reaction is 255°C. When the amount of water distilled in the esterification reaction reaches the theoretical level 90% of the value is the end point of the esterification reaction; then after the end of the esterification reaction, the polycondensation reaction in the low vacuum stage starts under negative pressure. The pressu...

PUM

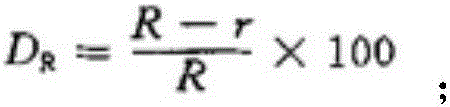

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| Ye chang | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com