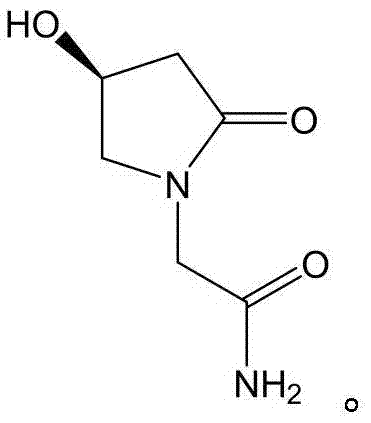

Levo oxiracetam oral cavity dispersing film preparation, and preparation method thereof

A technology for dispersing film and oral cavity, which is applied in the field of levoracetam orodispersible film and its preparation, which can solve the difficulty of controlling disintegration time and tensile strength, which restricts the development and application of orodispersible film, liposome Complicated preparation process and other issues to achieve the effect of improving bioavailability, avoiding elimination effect, and uniform and complete appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

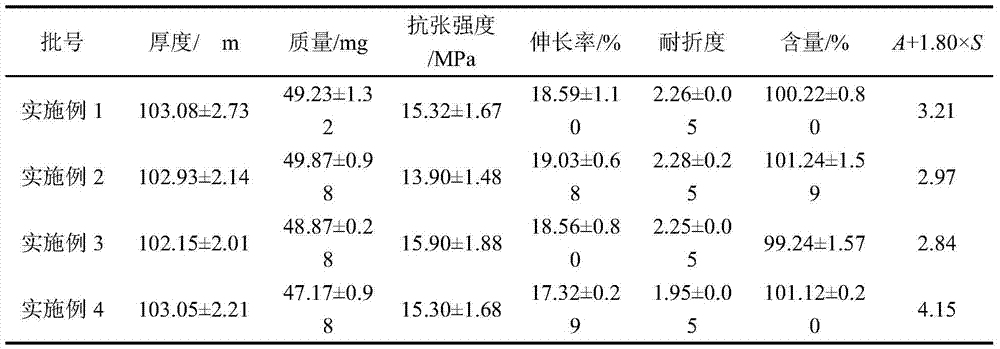

Embodiment 1

[0047] Mix 8 parts of levoxiracetam, 93 parts of hydroxypropylmethylcellulose, 8 parts of triethyl citrate, 5 parts of citric acid, and 2 parts of fructose, grind them thoroughly, mix them evenly, and pass them through a hot-melt laminating machine The feed zone of the feeder is sent to the hot melting zone, where it is melted at 80-85°C, and the molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

Embodiment 2

[0049] Mix 10 parts of levoxiracetam, 94 parts of hydroxypropylmethylcellulose, 8 parts of triethyl citrate, 5 parts of malic acid, and 3 parts of glucose, thoroughly grind and mix evenly, and pass through a hot-melt laminating machine The feeding zone of the feed zone is sent to the hot melting zone, where it is melted at 85-90°C, and the molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

[0050] The hot-melt lamination process can be carried out with reference to the following documents: Repka MA, Battu SK, Upadhye SB, etal. Pharmaceutical applications of hot-melt extrusion: part II [J]. Drug DevIndPharm, 2007, 33 (10): 1043-1057.

Embodiment 3

[0052] Mix 12 parts of levoxiracetam, 95 parts of polyoxyethylene, 8 parts of propylene glycol, 4 parts of saliva stimulant, and 3 parts of xylitol. Go to the hot-melt zone, heat-melt at 85-90°C, and the molten mixture is continuously output through the metering zone, poured into the mold, and forms a film after cooling.

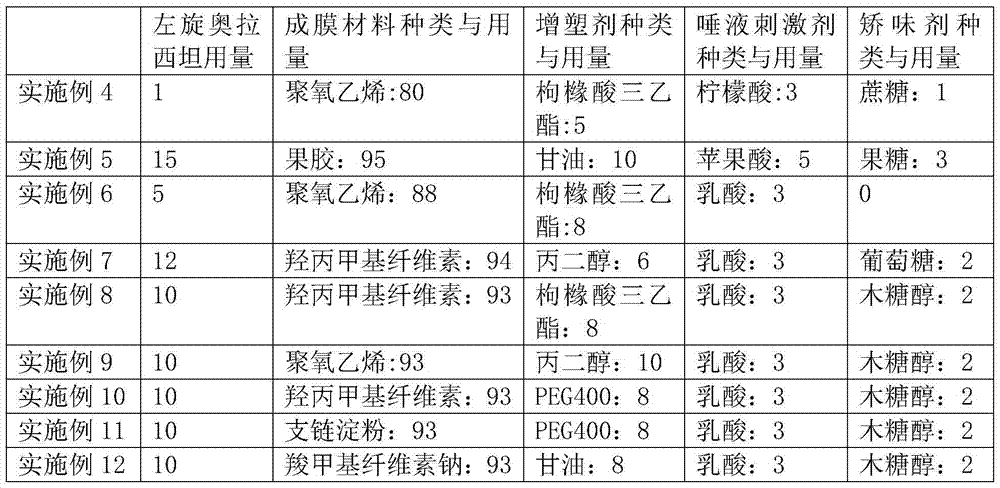

[0053] With reference to Examples 1-3, the following examples are prepared: (amounts in the following table are parts by weight)

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com