A kind of preparation method and application of graphene foam rectification column packing

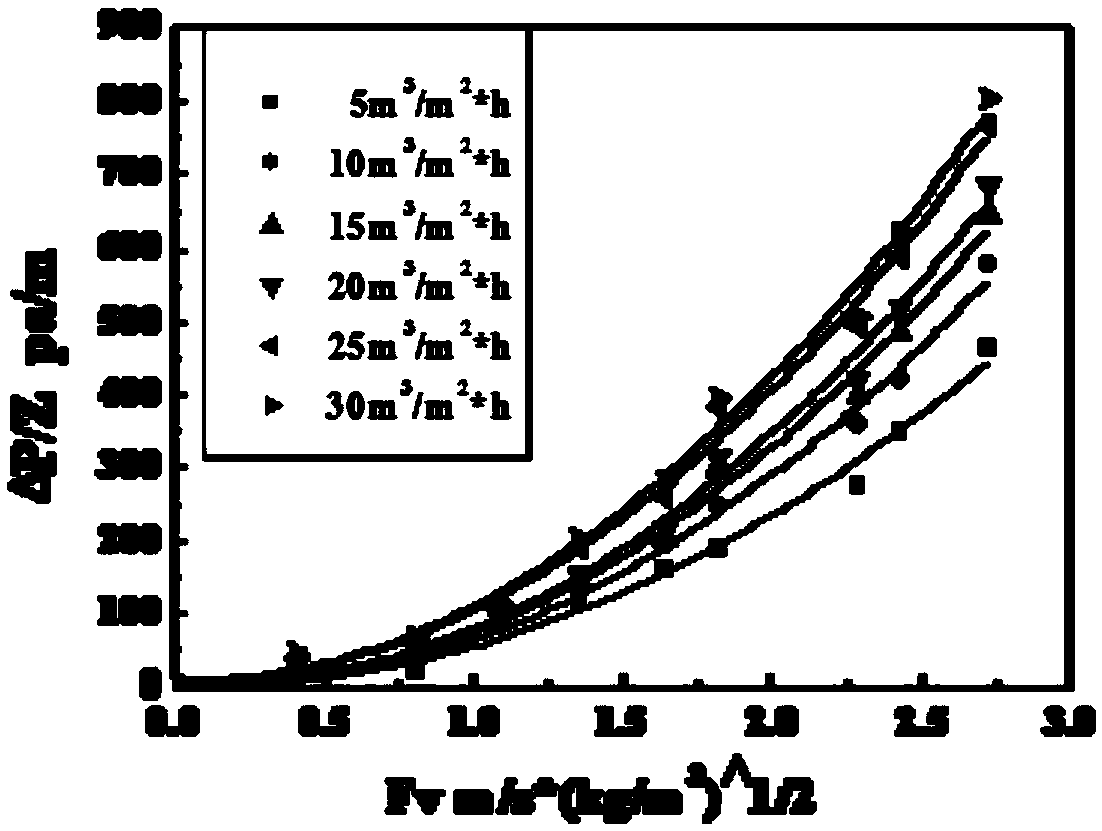

A technology of graphene foam and rectification tower, which is applied in separation methods, chemical instruments and methods, fractionation, etc., can solve the problems of high energy consumption for separation and large investment in equipment, and achieve improved distillation efficiency, reduced corrosion, and excellent The effect of adsorption and desorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

[0027] A kind of preparation method of novel graphene foam rectification tower filler, comprises the following steps:

[0028] 1) 50 mL of graphene oxide slurry with a concentration of 8 mg / mL was subjected to ultrasonic shock treatment for 30 min, then magnetically stirred, and 7 mL of Tween-80 / ethanol mixed solution with a concentration of 100-200 mg / mL was pipetted with a pipette gun and added dropwise to In the graphene oxide solution, after the solution is mixed evenly, continue to stir for 10 minutes; the thickness of the graphene oxide sheet is 2-5nm, which is single-layer, double-layer or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com