Meropenem palladium-carbon catalyst preparation method and catalyst prepared through same

A technology of palladium carbon catalyst and meropenem, which is applied in the field of chemical catalyst preparation, can solve problems such as cumbersome steps, harsh preparation requirements, and poor catalytic selectivity of the catalyst, and achieve simple preparation process, small negative impact on the environment, and improved reaction selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

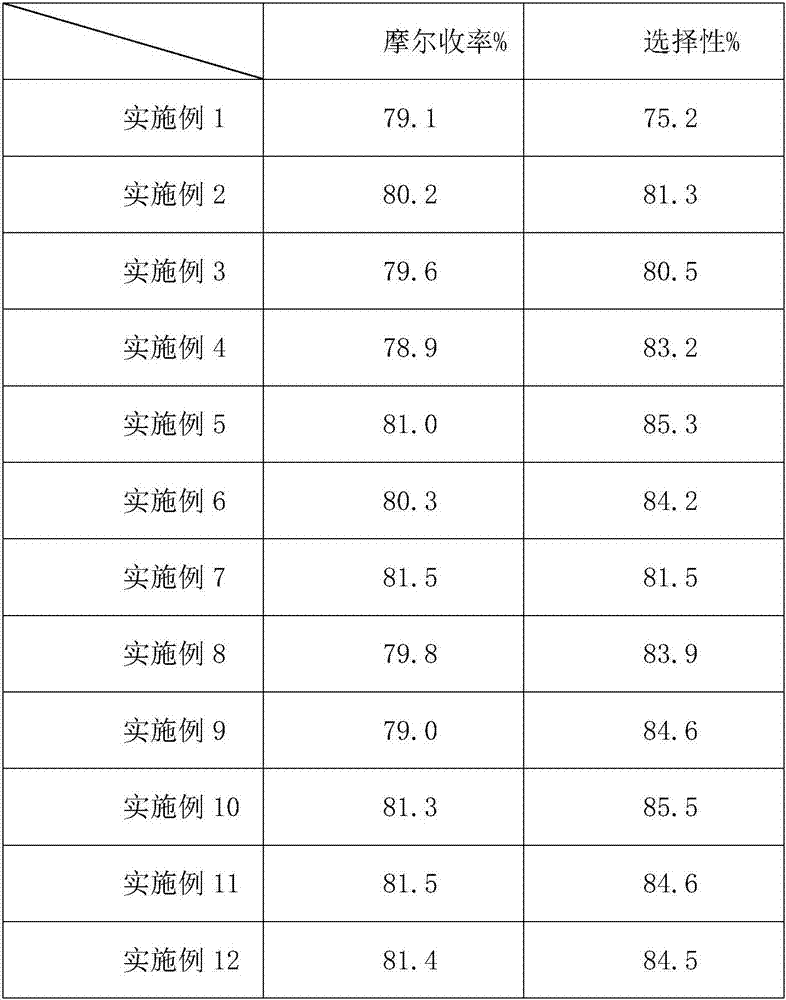

Examples

Embodiment 1

[0027] 1) Weigh palladium chloride, such as 1.68 g, dissolved in as little hydrochloric acid as possible, and then neutralize and react with, for example, a 1.0 mol / L sodium hydroxide aqueous solution to obtain palladium hydroxide precipitate, and wash with deionized water until there is no chloride ion.

[0028] 2) The freshly prepared palladium hydroxide is dissolved in as little as possible, for example, 4.0 moL / L sodium hydroxide solution, and the palladium concentration is diluted, for example, 0.1 moL / L.

[0029] 3) Control the temperature to 50°C-60°C, stir and adsorb the alkaline impregnation solution with, for example, 19.0g coconut shell activated carbon for a certain period of time, such as 4h, and impregnate the palladium solution onto the activated carbon carrier; in this embodiment, the activated carbon is preferably subjected to, for example, 5% nitric acid Boiling to activate, deionized water washing in this notice.

[0030] 4) Control the temperature to 80-100°C, and...

Embodiment 2

[0032] In this embodiment, except that potassium hydroxide is used instead of sodium hydroxide in step 2), other steps and parameters are preferably the same as those in embodiment 1.

Embodiment 3

[0034] In this embodiment, except that ammonium hydroxide is used instead of sodium hydroxide in step 2), other steps and parameters are preferably the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com