A kind of gear type trimerized perylene diimide compound and its preparation method and application

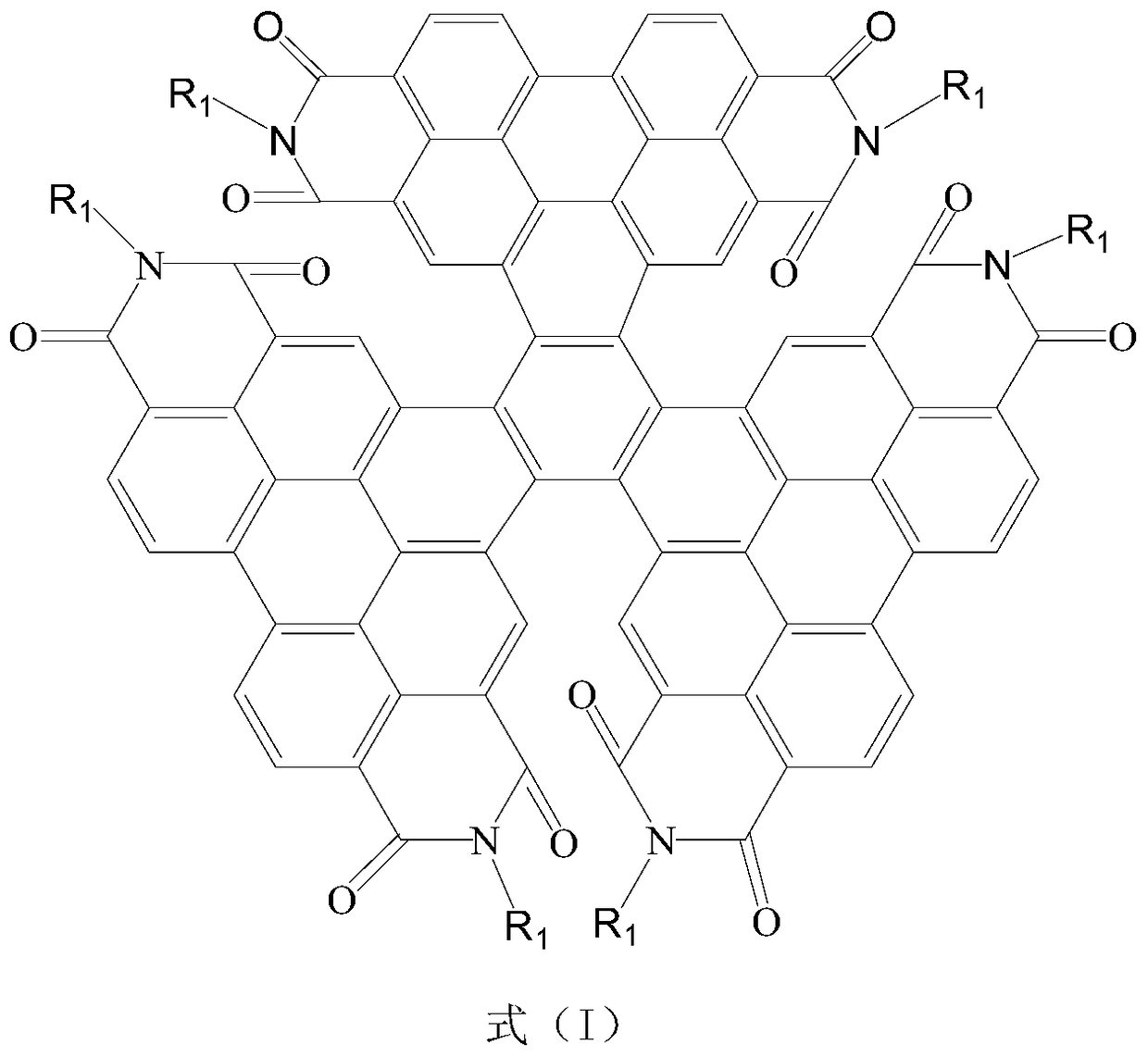

A technology of trimerized perylenediimide and bromoperyleneimide is applied in the field of gear-type trimerized perylenediimide compound and its preparation, so as to improve the photoelectric conversion efficiency, the design idea is reasonable and effective, and the molecular structure is simple. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

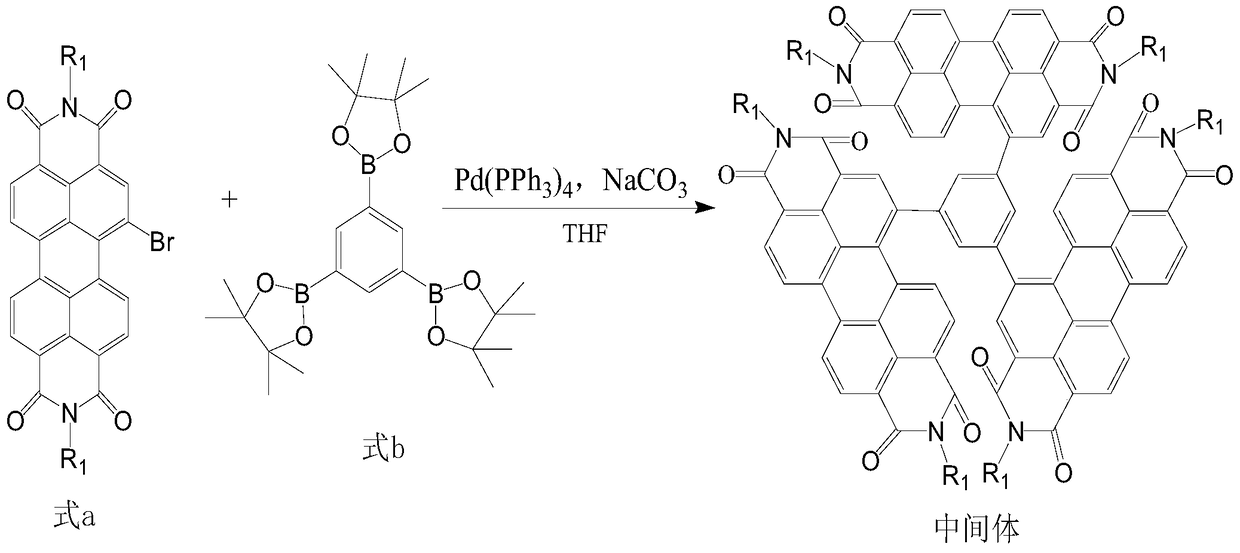

[0047] Embodiment 1, the preparation of target product 1

[0048] (1) Preparation of Intermediate 1

[0049] In a sealed glass tube, add monobromoperyleneimide (compound of formula a1) (546mg, 0.702mmol), 1,3,5-benzenetriborate (compound of formula b) (100mg, 0.219mmol), tetrahydrofuran 8ml and 4ml of 2M aqueous sodium carbonate solution. The mixture was sparged with argon for 30 min. Tetrakis(triphenylphosphine)palladium (35 mg, 0.026 mmol) was then added under argon. The mixture was heated to reflux for 48h, then cooled to room temperature, 25ml of water was added, extracted with dichloromethane (2×25ml), dried over anhydrous magnesium sulfate, filtered with suction, and the solvent was removed. The crude product was purified by chromatographic column to obtain an orange solid (367mg , 80%), namely intermediate 1. The reaction equation is as follows:

[0050]

[0051] The structural confirmation data of intermediate 1 are as follows: 1 H NMR (400MHz, CDCl 3 )δ=8.67...

Embodiment 2

[0056] Embodiment 2, the preparation of target product 2

[0057] The structural formula of the target product 2 that the present embodiment makes is as follows:

[0058]

[0059] The preparation method is as follows:

[0060] 1) Using tetrahydrofuran and aqueous sodium carbonate as solvents and tetrakis(triphenylphosphine)palladium as a catalyst, heat and reflux monobromoperyleneimide (compound of formula a2) and 1,3,5-benzenetriboronate for 45 hours, intermediate 2 is obtained; wherein, the molar ratio of the monobromoperyleneimide (compound of formula a2) and 1,3,5-benzenetriboronate is 3:1;

[0061]

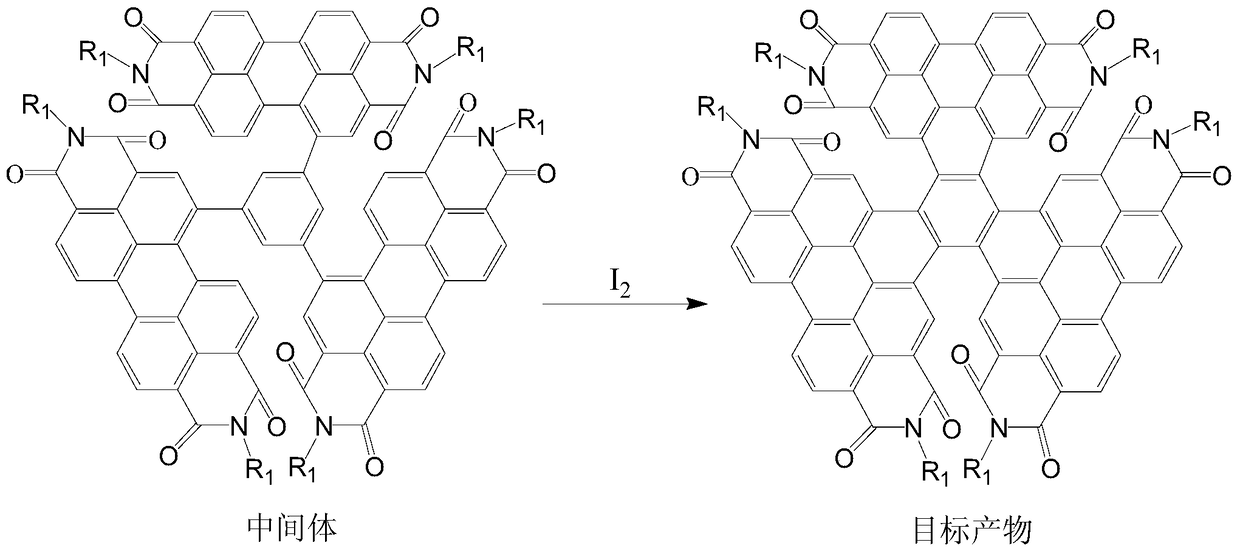

[0062] 2) Intermediate 2, I 2 The mixture with toluene was irradiated under a mercury lamp for 10h and then extracted with a saturated aqueous solution of sodium sulfite, then washed, dried, filtered, and purified by a chromatographic column to obtain the target product 2; wherein, intermediate 2 and I 2 The mass ratio of intermediate 2 and toluene is 1:1; the mass v...

Embodiment 3

[0063] Embodiment 3, the preparation of target product 3

[0064] The structural formula of the target product 3 that present embodiment makes is as follows:

[0065]

[0066] The preparation method is as follows:

[0067] 1) Using tetrahydrofuran and aqueous sodium carbonate as solvents and tetrakis(triphenylphosphine) palladium as a catalyst, heat monobromoperylene imide (compound of formula a3) and 1,3,5-benzenetriboronate under reflux for 50 hours, intermediate 3 is obtained; wherein, the molar ratio of the monobromoperyleneimide (compound of formula a3) and 1,3,5-benzenetriboronate is 3.5:1;

[0068]

[0069] 2) Intermediate 3, I 2 The mixture with toluene was irradiated under a mercury lamp for 15h and then extracted with a saturated aqueous solution of sodium sulfite, then washed, dried, filtered, and purified by a chromatographic column to obtain the target product 3; wherein, intermediate 3 and I 2 The mass ratio of intermediate 3 to toluene is 3:1; the mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com