High-density transition metal monoatomic load graphene-based catalyst and preparation method thereof

An alkenyl catalyst, transition metal technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of low loading, complicated preparation methods, restricting commercial applications, etc., and achieve high single-atom loading and high activity. The effect of site density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] a. Weigh 0.25g of glucose and 5g of dicyandiamide and dissolve the two in 200mL of deionized water (note that due to the low solubility of dicyandiamide in water, it is necessary to increase its mass while adding water amount until the reagent is completely dissolved);

[0048] b. Use a pipette gun to measure 2 mL of the prepared ferric chloride solution with a molar concentration of 0.0125 mol / L, and add it dropwise to the dissolved glucose and dicyandiamide solution;

[0049] c. Put the solution containing the precursor prepared above and evaporate it to dryness on a heating platform at 80°C, then take it out and grind it into a uniform powder with a mortar, put it into a suitable size quartz boat or corundum boat and add cover;

[0050] d. Next, place the whole ark in a tube furnace, and calcinate it at 900° C. for 2 hours under an inert atmosphere (nitrogen or argon), and lower the temperature naturally.

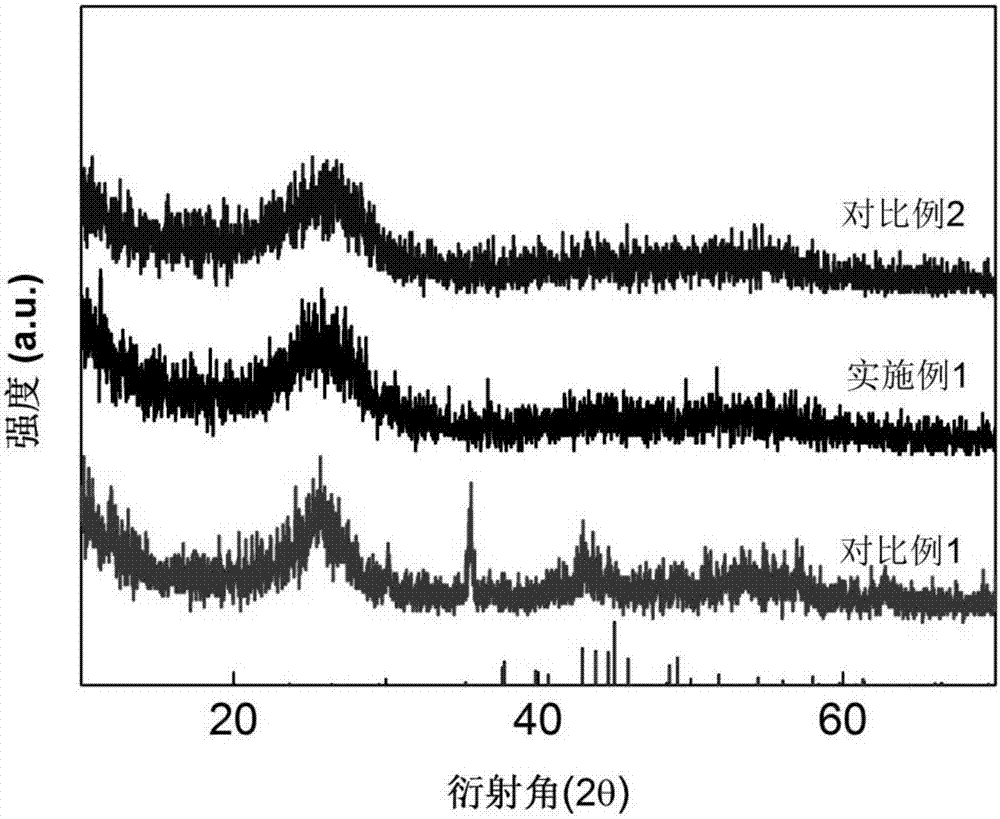

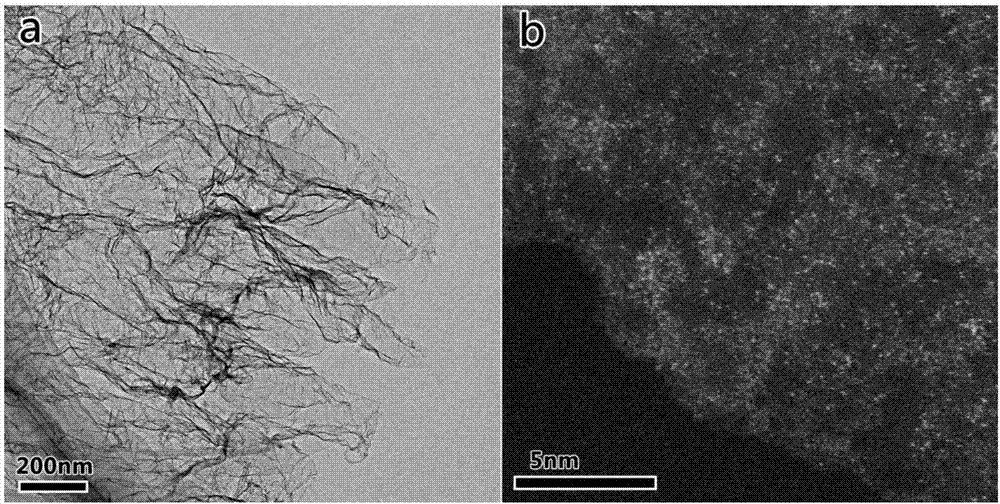

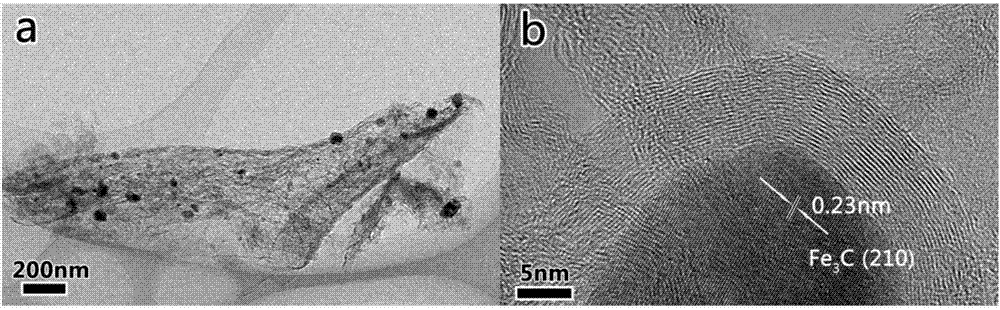

[0051] Adopt XRD to detect the prepared catalyst, the resu...

Embodiment 2

[0064] Test and evaluate the oxygen reduction performance of Example 1, Comparative Example 1, Comparative Example 2 and 20 wt% commercial platinum carbon in 0.1 mol / L KOH electrolyte. The test steps and results are described as follows:

[0065] Take 5 mg of Example 1, Comparative Example 1, Comparative Example 2 and 20wt% commercial platinum carbon samples respectively, add 950 μL of isopropanol and water mixed solvent (both volume ratio is 1:1), and add 50 μL of mass concentration of 5% Nafion was used as a binder, ultrasonically dispersed for about 2 hours to obtain a uniformly dispersed sample solution. Then, 10 μL of the prepared solution was taken out and drop-coated on a rotating disk electrode with a diameter of 5 mm, and then dried at room temperature to form a film for performance characterization.

[0066] Select the saturated Ag / AgCl electrode as the reference electrode, the graphite rod as the counter electrode, and the rotating disk electrode of the drip-coated...

Embodiment 3

[0068] Test Evaluation Example 1, Comparative Example 1, Comparative Example 2 and 20wt% commercial platinum carbon in 0.1mol / L HClO 4 Oxygen reduction performance in electrolytes. The test steps and results are described as follows:

[0069] Take 5 mg of Example 1, Comparative Example 1, Comparative Example 2 and 20wt% commercial platinum carbon samples respectively, add 950 μL of isopropanol and water mixed solvent (both volume ratio is 1:1), and add 50 μL of mass concentration of 5% Nafion was used as a binder, ultrasonically dispersed for about 2 hours to obtain a uniformly dispersed sample solution. Then, 10 μL of the prepared solution was taken out and drop-coated on a rotating disk electrode with a diameter of 5 mm, and then dried at room temperature to form a film for performance characterization.

[0070] Select the saturated Ag / AgCl electrode as the reference electrode, the graphite rod as the counter electrode, and the rotating disk electrode of the drip-coated sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com