New nutrient-rich feed for pigs

A nutrient-rich, pig feed technology, applied in animal feed, animal feed, additional food elements, etc., can solve problems such as reducing the ability of animals to resist diseases, affecting the quality and taste of meat products, and low feed intake of suckling pigs. The effect of improving the body's disease resistance, improving feed conversion rate and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

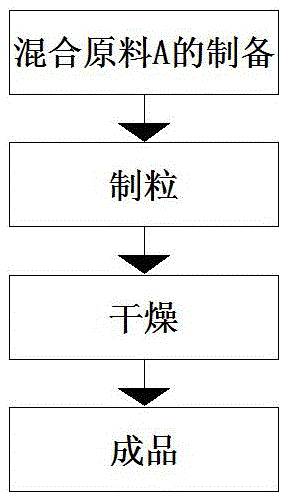

Method used

Image

Examples

Embodiment 1

[0019] A new type of nutrient-rich pig feed. The composition ratio (parts by mass) of the pig feed includes 10 parts of millet noodles, 7 parts of wheat bran, 8 parts of straw meal, 9 parts of bean cake, 5 parts of rice bran, and 6 parts of fish meal. , 10 parts salt, 4 parts premix, 7 parts soybean oil, 9 parts multivitamins, 7 parts emulsified fat powder, 3 parts calcium dihydrogen phosphate, 6 parts glucose powder, 4 parts intestinal membrane protein powder, 5 parts sodium butyrate , 7 parts of lysine, 6 parts of threonine, 5 parts of methionine and 5 parts of auxiliary ingredients, the auxiliary ingredients are a mixture of licorice, wolfberry and yam, and the mass ratio of licorice, wolfberry and yam is 2:3: 5. The preparation method of the auxiliary ingredients is (1) Put the wolfberry and yam in a container and boil it at 70°C for 45 minutes, then remove it and dry it; (2) Put it in a blender and add licorice to stir evenly, Transfer to a pulverizer for pulverization to ...

Embodiment 2

[0025] Example 2: The rest is the same as Example 1, except that the mass ratio of licorice, wolfberry and yam is 3:4:6, and the preparation method of the auxiliary ingredients is (1) placing wolfberry and yam in a container Neutralize and boil at 75°C for 50 minutes, then remove and dry; (2) Put it in a mixer and add licorice to stir evenly, transfer to a grinder for pulverization to prepare the auxiliary ingredients; the step ( In 1), take 25% of the raw materials and stir for 25 minutes in a blender, then add 28ml of water to the blender, continue to slowly add the remaining raw materials into the blender and stir evenly to obtain a batter-like mixed raw material A; the step (3) In the process, the above-mentioned pig feed pellets are placed in a dryer and dried at a constant temperature of 38° C. for 40 minutes, and the moisture content of the obtained feed pellets is 3%.

Embodiment 3

[0026] Example 3: The rest is the same as Example 1, except that the mass ratio of licorice, wolfberry and yam is 6:7:8, and the preparation method of the auxiliary ingredients is (1) placing wolfberry and yam in a container Neutralize and boil in water at 90°C for 65 minutes, then remove and dry; (2) Put it in a mixer and add licorice to stir evenly, transfer to a pulverizer for pulverization, and prepare the auxiliary ingredients; the step ( In 1), take 35% of the raw materials and stir for 30 minutes in a blender, then add 30ml of water to the blender, continue to slowly add the remaining raw materials into the blender and stir evenly to obtain a batter-like mixed raw material A; the step (2) In the process, the mixed raw materials are placed in a conventional pelletizer to make mixed pig feed pellets with a diameter of 12 mm.

[0027] After the above process steps, take out the pig feed sample for testing:

[0028] Serial number Shelf life / year Protein content / % Vitamin c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com