Natural extracellular matrix biological membrane as well as preparation method and applications thereof

A technology of exogenous matrix and biofilm, applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of material hydrophilicity, degradation time and mechanical strength, insufficient exposure, etc., to achieve longer degradation time in vivo, The effect of eliminating hydrophilic groups and increasing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Natural extracellular matrix biofilm and preparation method thereof

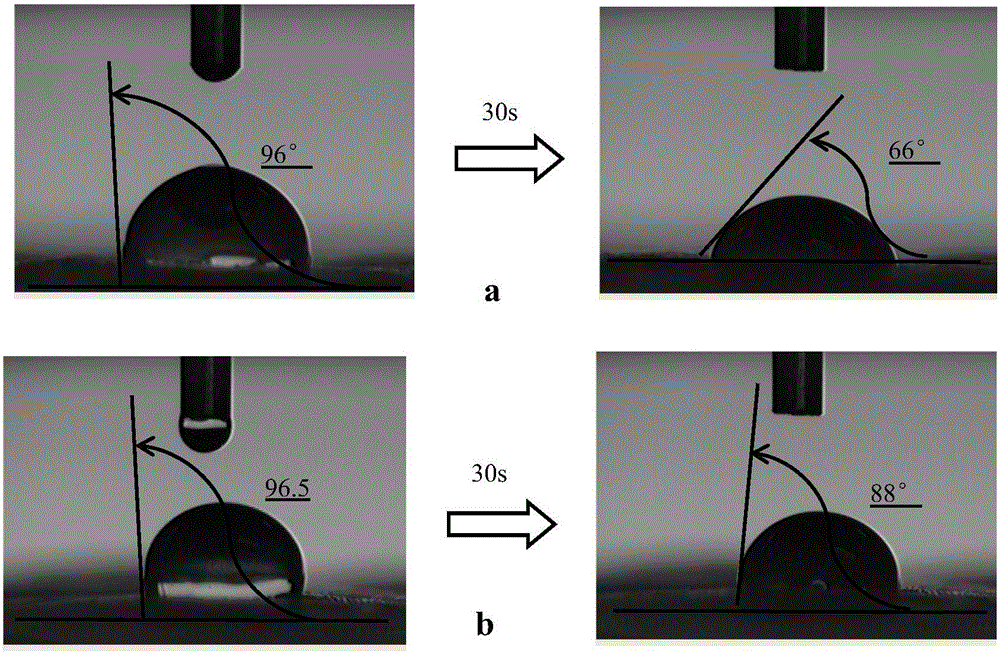

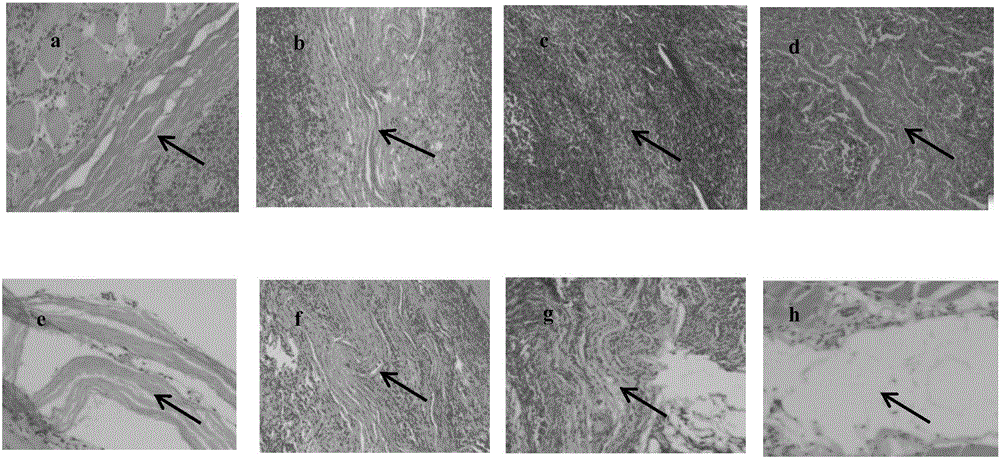

[0025] The meat joint factory purchases 1 pair of fresh pig small intestines, pre-treatment and cleaning to remove intestinal chyme, and cuts into intestines with a length of about 1 meter; prepares 3L of peracetic acid solution with a concentration of 0.5%, and puts the above intestines into peroxygen Soak in acetic acid solution for 1 hour, stir once every 10 minutes; wash the above-mentioned sterilized intestinal segment 5-8 times until the pH is 6.0-7.0; use an intestinal peeling machine to peel off the intestinal tissue to obtain the small intestinal submucosa; the prepared concentration is 0.05M sodium hydroxide solution, soak the above small intestinal submucosa in alkaline solution for 10 minutes, then soak in purified water for 10 minutes, repeat 3 times; wash the above small intestinal submucosa with purified water repeatedly 10 times; clean the small intestinal submucosa Lay 4 ove...

Embodiment 2

[0026] Example 2 Natural extracellular matrix biofilm and its preparation method

[0027] The meat joint factory purchases 1 pair of fresh pig small intestines, pre-treatment and cleaning to remove intestinal chyme, and cuts into intestines with a length of about 1 meter; prepares 3L of peracetic acid solution with a concentration of 0.5%, and puts the above intestines into peroxygen Soak in acetic acid solution for 1 hour, stir once every 10 minutes; wash the above-mentioned sterilized intestinal segment 5-8 times until the pH is 6.0-7.0; use an intestinal peeling machine to peel off the intestinal tissue to obtain the small intestinal submucosa; the prepared concentration is 0.25% sodium dodecylsulfonate (SDS) solution, soak the above small intestinal submucosa in SDS solution for 10 minutes, repeat 4 times; wash the above small intestinal submucosa with purified water for 10 times; wash the small intestinal submucosa Lay 4 overlapping layers, clamp the clamps, and freeze-dr...

Embodiment 3

[0028] Example 3 Natural extracellular matrix biofilm and its preparation method

[0029] The meat joint factory purchases 1 pair of fresh pig small intestines, pre-treatment and cleaning to remove intestinal chyme, and cuts into intestines with a length of about 1 meter; prepares 3L of peracetic acid solution with a concentration of 0.5%, and puts the above intestines into peroxygen Soak in acetic acid solution for 1 hour, stir once every 10 minutes; wash the above-mentioned sterilized intestinal segment 5-8 times until the pH is 6.0-7.0; use an intestinal peeling machine to peel off the intestinal tissue to obtain the small intestinal submucosa; the prepared concentration is 0.05M sodium hydroxide solution, soak the above small intestinal submucosa in alkaline solution for 10 minutes, then soak in purified water for 10 minutes, repeat 3 times; wash the above small intestinal submucosa with purified water repeatedly 10 times; clean the small intestinal submucosa Lay 4 overlap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com