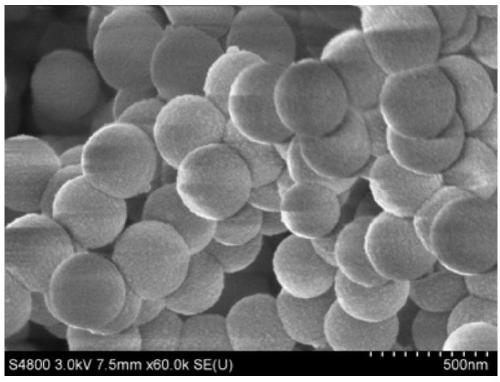

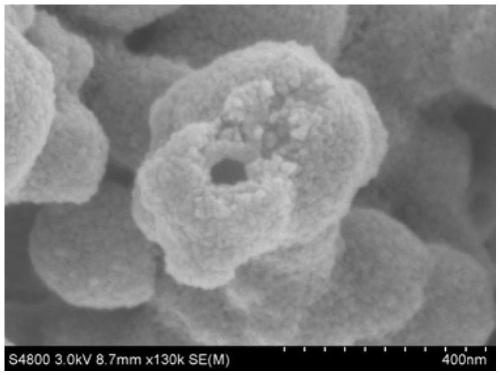

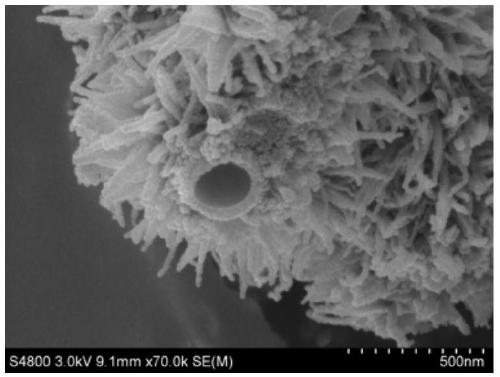

A kind of sea urchin-shaped double-shell hollow microsphere and its preparation method

A double-shell, sea urchin-like technology, applied in the field of nanomaterials, achieves the effects of regular morphology, good barrier properties and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Measure 15mL polystyrene microsphere emulsion, dilute it with 18mL distilled water and 75mL isopropanol, then adjust the pH value to 9.5 with ammonia water, add 1g tetraethyl orthosilicate dropwise with a rubber dropper, and drop it for about 2 minutes , then mechanically stirred at 40°C and 300r / min for 5h, the product was centrifuged, washed with isopropanol for 1 to 3 times, and dried in an oven at 50°C for 4h to obtain polystyrene / dioxide with a particle size of 50nm to 500nm Silicon core-shell particles.

[0031] (2) Weigh 0.03g of polystyrene / silica core-shell particles, disperse them in 15mL of absolute ethanol by ultrasonic (the power of ultrasonic is 500W, and the time is 10min), and then add 24mL of titanium with a mass concentration of 1%. After the addition of tetrabutyl ester in absolute ethanol, react at 300r / min and 75°C for 4h, centrifuge the product, and wash it with absolute ethanol for 1 to 3 times to obtain polystyrene / silicon dioxide / titanium di...

Embodiment 2

[0034] (1) Measure 22mL polystyrene microsphere emulsion, dilute it with 21mL distilled water and 81mL isopropanol, then adjust the pH value to 10.0 with ammonia water, add 1.4g tetraethyl orthosilicate dropwise with a rubber dropper for about 2 minutes After completion, mechanically stir at 50°C and 300r / min for 5h, centrifuge the product and wash it with isopropanol for 1 to 3 times, and dry it in an oven at 40°C for 6h to obtain polystyrene / dicarbonate with a particle size of 50nm to 500nm. Silica core-shell particles.

[0035](2) Weigh 0.09g of polystyrene / silica core-shell particles, disperse them in 18mL of absolute ethanol by ultrasonic (the power of ultrasonic is 200W, and the time is 20min), and then add 24mL of titanium with a mass concentration of 1%. After the addition of tetrabutyl ester in absolute ethanol, react at 300r / min and 75°C for 3h, centrifuge the product and wash it with absolute ethanol for 1 to 3 times to obtain polystyrene / silicon dioxide / titanium di...

Embodiment 3

[0038] (1) Measure 24mL polystyrene microsphere emulsion, dilute it with 22mL distilled water and 82mL isopropanol, then adjust the pH value to 10.1 with ammonia water, add 1.8g tetraethyl orthosilicate dropwise with a rubber dropper for about 3 minutes After completion, mechanically stir at 60°C and 300r / min for 6h, centrifuge the product, wash with isopropanol for 1 to 3 times, and dry in an oven at 60°C for 4h to obtain polystyrene / dicarbonate with a particle size of 50nm to 500nm. Silica core-shell particles.

[0039] (2) Weigh 0.07g of polystyrene / silica core-shell particles, disperse them in 21mL of absolute ethanol by ultrasonic (the power of ultrasonic is 300W, and the time is 15min), and then add 24mL of titanium with a mass concentration of 1%. After the addition of tetrabutyl ester in absolute ethanol, react at 300r / min and 80°C for 3h, centrifuge the product and wash it with absolute ethanol for 1-3 times to obtain polystyrene / silicon dioxide / titanium dioxide For ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com