Photocurable adhesive composition for screen edge sealing and use thereof

A technology of adhesives and compositions, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of not being able to obtain UV curing speed, OD value, and high bonding strength at the same time, and achieve increased elasticity , Guarantee the bonding strength and the effect of enhancing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

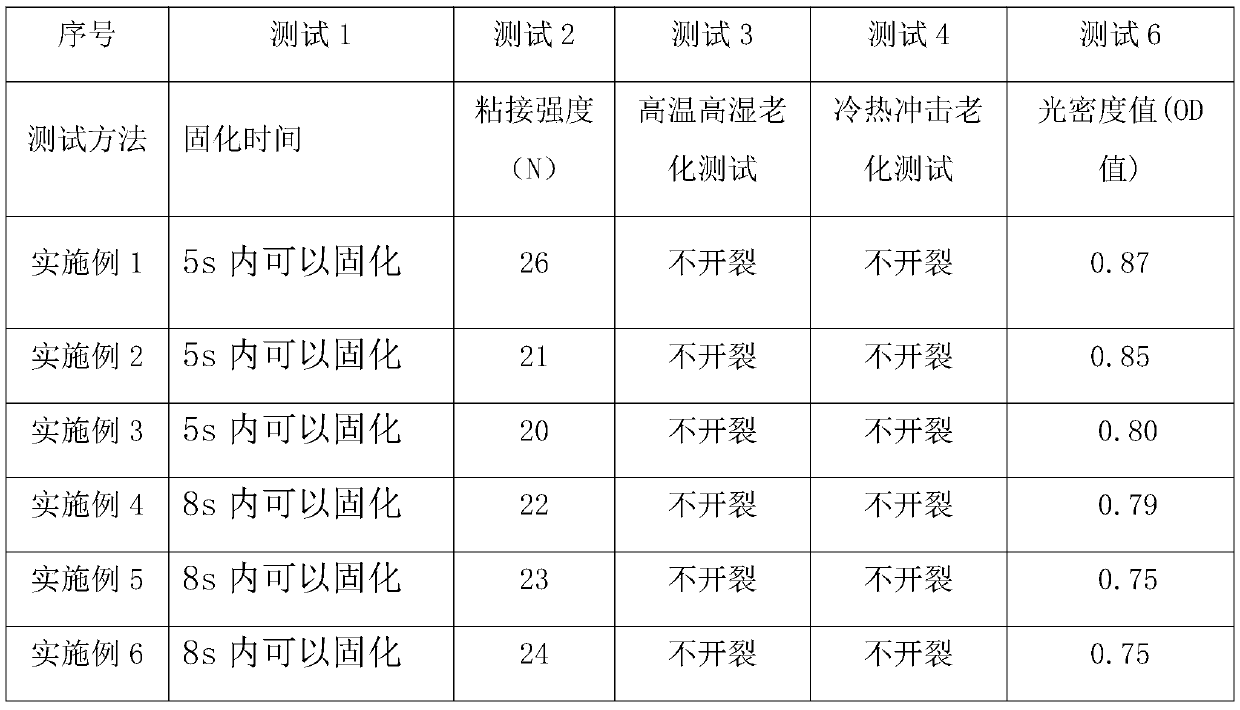

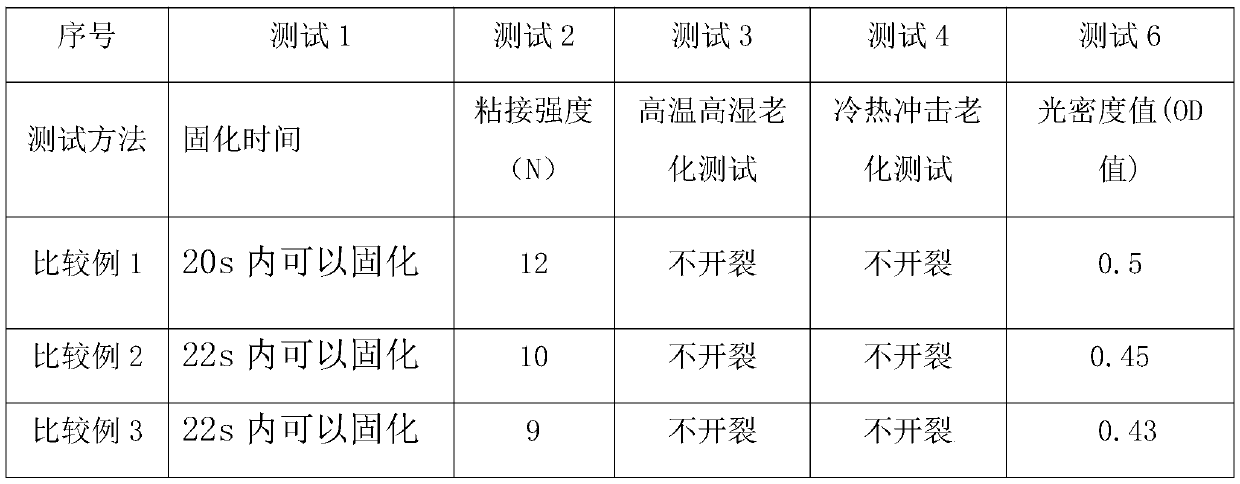

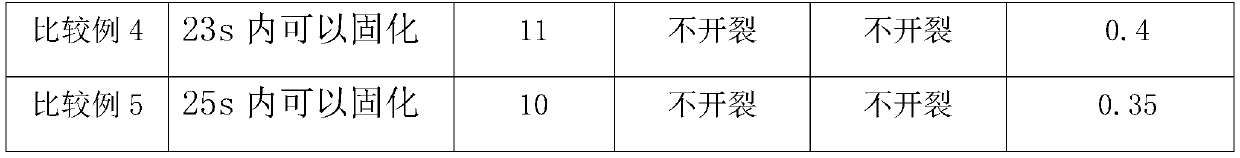

Examples

preparation example Construction

[0026] A photocurable adhesive composition for screen edge sealing and its use and a preparation method thereof, comprising the following steps:

[0027] The adhesive composition of the present invention can be prepared by putting each raw material of the adhesive composition into the mixing tank in turn according to the ratio requirement, and stirring according to a certain speed and time. The preparation process is carried out under normal temperature and pressure, and needs to be protected from light.

[0028] Zirconium carbide powder described below is selected from Changsha Langfeng Metal Material Co., Ltd.

[0029] The BL 1226 and IRA OYP01 mentioned below are all selected from Qingdao Jiedejia New Material Technology Co., Ltd.

Embodiment 1

[0031] In the first step, put 55kg of aliphatic urethane acrylate, 25kg of 2-(ethoxy)ethoxyethyl acrylic acid and 10kg of hydroxyethyl acrylate into the mixing tank for stirring, and set the stirring speed at about 90-120rpm , stirring for about 10 minutes; the second step, weigh 3kg 1-hydroxycyclohexyl phenyl ketone and 1kg 2,4,6-trimethylbenzoyl-diphenylphosphine oxide or put them into the mixing tank for stirring , the stirring speed is set at about 100-120rpm, and the stirring time is about 20 minutes; in the third step, 1kg of zirconium carbide powder, 1kg of BL 1226 and 4kg of carbon black are put into the mixing tank for stirring, and the stirring speed is set at about 15-30rpm, and the stirring time is For 25 minutes, finally the mixture can be filtered and packaged.

Embodiment 2

[0033] In the first step, weigh 50kg of aliphatic urethane acrylate, 18kg of tetraethylene glycol diacrylate, 10kg of ethoxylated trimethylolpropane triacrylate and 10kg of hydroxypropyl acrylate and put them into the mixing tank for stirring , the stirring speed is set to about 60-120rpm, stirring for about 10 minutes; the second step, 2kg2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone, 0.5kg Isopropylthioxanthone (2, 4 isomeric mixture), 1kg of isooctyl p-N,N-dimethylaminobenzoate and 1.5kg of methyl o-benzoylbenzoate were weighed and put into the mixing tank for stirring , the stirring speed is set at about 100-120rpm, and the stirring time is about 20 minutes; in the third step, 1kg of zirconium carbide powder, 1kg BL 1226, 1kg IRA OYP01 and 4kg of carbon black are put into the mixing tank for stirring, and the stirring speed is set at about 15- 30rpm, the stirring time is 25 minutes, and finally the mixture can be filtered and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com