A method for processing and utilizing cracked C9 distillate oil

A distillate oil and petroleum cracking technology, which is applied in the fields of hydrocarbon oil cracking, petroleum industry, chemical instruments and methods, etc., can solve the problems of easy deactivation of catalysts and difficult treatment, and achieves alleviation of coking, low concentration, and delayed deactivation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and 2

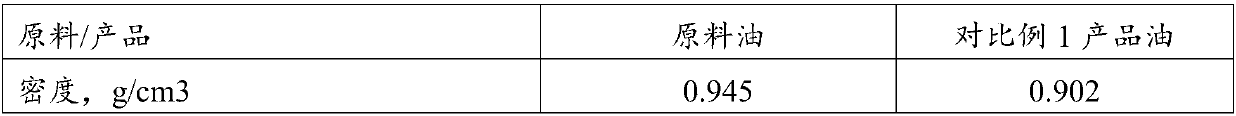

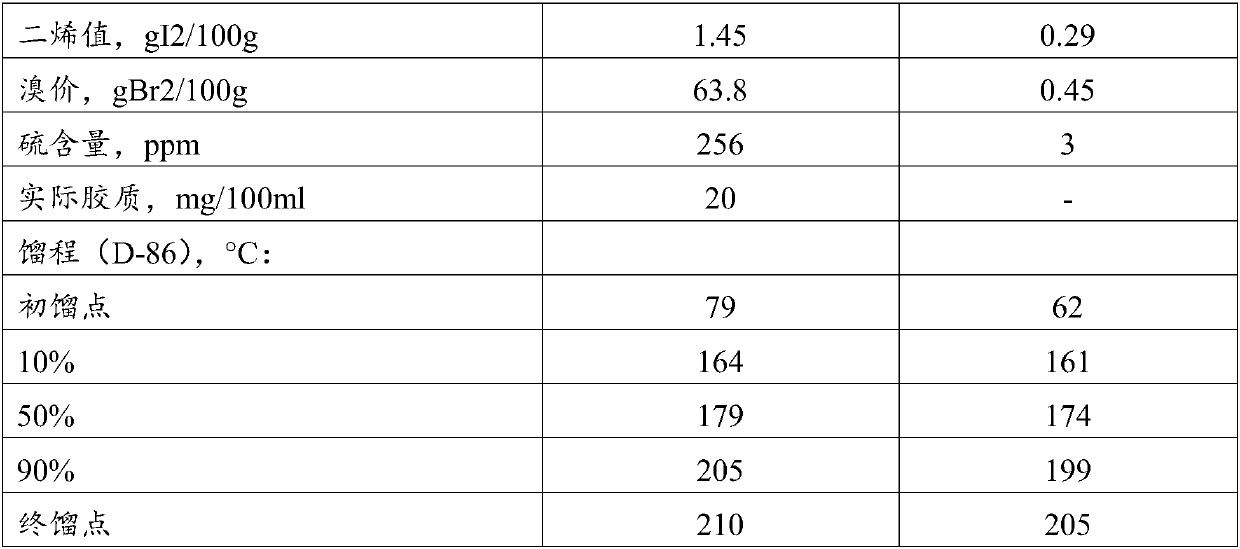

[0041] The raw oil is the same as that of Comparative Example 1, and its properties are shown in Table 1.

[0042] The catalyst used in the reaction is obtained as follows: the aqueous solution of nickel nitrate, cobalt nitrate and molybdenum nitrate pentahydrate is mixed and heated at 45°C to prepare a stable co-immersion solution. The co-impregnation solution is impregnated on the alumina support in a saturated impregnation manner. Then drying at 120°C for 6 hours and calcining at 560°C for 4 hours to prepare a Ni-Mo-Co ternary supported hydrofining catalyst. The amount of metal active components on the catalyst is regulated by the amount of each metal component in the impregnation solution. The physical and chemical properties of the catalysts prepared by calcination are shown in Table 3.

Embodiment 1

[0043] The process conditions adopted in Examples 1 and 2 are shown in Table 4. As can be seen from Table 4, two groups of process condition tests were carried out for the hydrogenation reaction, which are respectively Example 1 and Example 2. The operating pressure in the two examples is the same, which is 4.0 MPa. In embodiment 1, the volumetric space velocity of raw material oil is 0.5h -1 , the liquid circulation ratio (volume ratio) is 1:5.0, the hydrogen-oil ratio at the reactor inlet is 160v / v, and when the reactor inlet temperature is 190°C, the catalyst bed temperature reaches 271°C.

Embodiment 2

[0044] Compared with Example 1, Example 2 increases the liquid circulation rate, the circulation ratio is 1:10.0, and the hydrogen flow rate is the same as that of Example 1, so the hydrogen-to-oil ratio drops to 80, and the reactor inlet temperature is correspondingly increased to 205°C, and the catalyst The bed temperature was 267°C.

[0045] The product property that embodiment obtains is shown in Table 5. As can be seen from Table 5, using the technology of the present invention, under the single-stage hydrogenation process flow, the cracked C9 distillate raw material has been well hydrotreated, the sulfur content of the liquid product2 / 100g, a qualified blended gasoline component has been obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com