Preparation of magnetically separable cyclodextrin organic phosphonic acid inclusion compound and application of inclusion compound in heavy metal ions in industrial wastewater

An organic phosphonic acid and cyclodextrin technology, which is applied in the field of nanomaterials and heavy metal adsorption, can solve problems such as difficult modification, and achieve the effect of small environmental impact, convenient and quick recycling and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

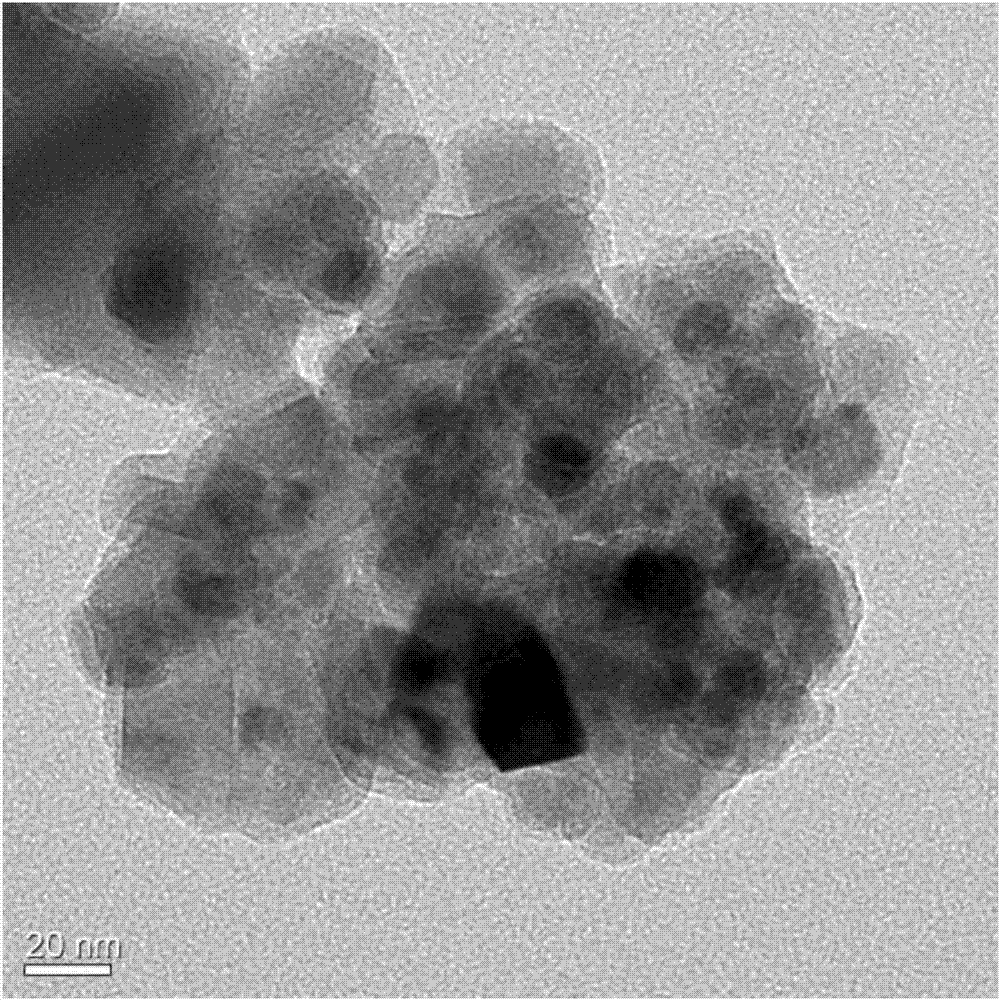

[0032] (1) Preparation of Fe by solvothermal method 3 o 4 nanoparticles

[0033] FeCl 3 ·6H 2 O (1 g) was dissolved in ethylene glycol (20 mL), followed by the addition of CH 3 COONa (3 g) and 1,2-ethylenediamine (10 mL). The mixture was stirred vigorously for 30 minutes and then sealed into a stainless steel autoclave with a Teflon liner. The reaction was continued at 200° C. for 8 h, and the resulting black substance was washed with water several times after cooling to room temperature.

[0034] (2) Fe 3 o 4 Preparation of @CD

[0035] Will Fe 3 o 4 (0.5g) and sodium dodecylbenzenesulfonate (1g) were added to the NaOH solution (0.01mol·L -1 , 50mL), sonicate for 20min, add dropwise an appropriate amount of epichlorohydrin and react at 80°C for 24h. After the reactant was cooled to room temperature, the pH was adjusted to 4-6 with HCl, the modified nanoparticles were magnetically separated, washed with deionized water several times to remove unreacted CM-β-CD, and...

Embodiment 2

[0042] (1) Preparation of Fe by solvothermal method 3 o 4 nanoparticles

[0043] FeCl 3 ·6H 2 O (1 g) was dissolved in ethylene glycol (20 mL), followed by the addition of CH 3 COONa (3 g) and 1,2-ethylenediamine (10 mL). The mixture was stirred vigorously for 30 minutes and then sealed into a stainless steel autoclave with a Teflon liner. The reaction was continued at 200° C. for 8 h, and the resulting black substance was washed with water several times after cooling to room temperature.

[0044] (2) Fe 3 o 4 Preparation of @CD

[0045] Will Fe 3 o 4 (0.5g) and sodium dodecylbenzenesulfonate (1g) were added to the NaOH solution (0.01mol·L -1 , 50mL), sonicate for 20min, add dropwise an appropriate amount of epichlorohydrin and react at 80°C for 24h. After the reactant was cooled to room temperature, the pH was adjusted to 4-6 with HCl, the modified nanoparticles were magnetically separated, washed several times with deionized water to remove unreacted CM-β-CD, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com