A kind of treatment method of waste acid water

A treatment method and technology for waste acid water, which are applied in multi-stage water treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc., which can solve the need for desulfurization treatment of exhaust gas, high equipment quality requirements, and large investment in environmental protection treatment. and other problems, to achieve the effect of reducing energy consumption, short processing flow and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

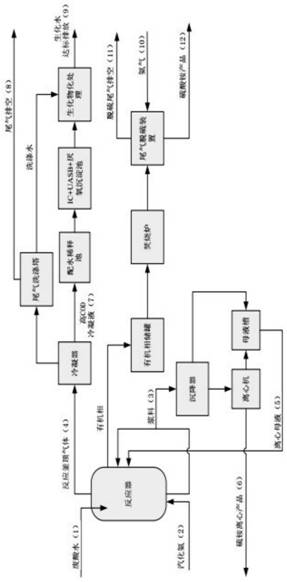

Method used

Image

Examples

Embodiment 1

[0026] A method for treating waste acid water, wherein, the waste acid water is the waste acid water produced in the process of preparing methyl methacrylate by the ACH method, and the waste acid water contains 33.21% water and 14.02% sulfuric acid in percent by mass. %, ammonium bisulfate 45.50%, MMA 0.1%, methanol 0.5%, acetone 0.1%, methacrylic acid sodium salt 0.4%, methacrylic acid polymer 5.5%, methacrylic acid and methacrylic acid oligomer 0.3% , a small amount of α-hydroxyisobutyric acid, acetone monosulfonic acid, acetone disulfonic acid, etc.; specifically follow the steps below for intermittent operation:

[0027] Before the reaction, feed a small amount of water into the reactor, then add part of the waste acid water, and then continuously feed the remaining waste acid water and all the ammonia gas to control the pH at the end of the reaction to 6.0; the gas coming out of the top of the reactor is directly Pass it into the middle of the rectification tower for rect...

Embodiment 2

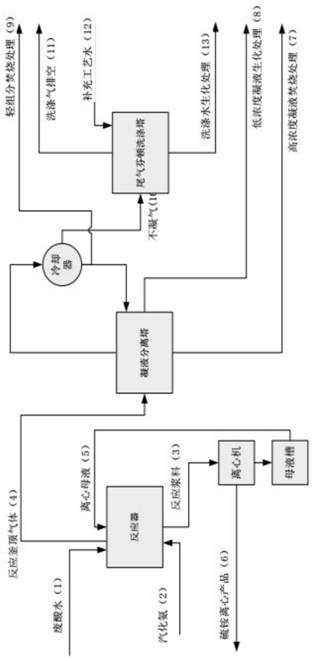

[0030] A method for treating waste acid water, wherein, the waste acid water is the waste acid water produced in the process of preparing methyl methacrylate by the ACH method, and the waste acid water contains 33.21% water and 14.02% sulfuric acid in percent by mass. %, ammonium bisulfate 45.50%, and a small amount of organic matter; it specifically performs intermittent operation according to the following steps, and its technological process diagram is attached figure 2 Shown:

[0031] Before the reaction, feed a small amount of water into the reactor, then add part of the waste acid water, and then continuously feed the remaining waste acid water and all the ammonia gas to control the pH at the end of the reaction to 6.0; the gas coming out of the top of the reactor is directly Pass it into the middle of the rectification tower for rectification separation, control the temperature of the tower bottom to 130°C, and the temperature of the tower top to 30°C; send the high-conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com