Loess particle grafted copolymer adsorbent and preparation method thereof

A graft copolymer and adsorbent technology, applied in the field of loess-based adsorbents, can solve the problems of expensive, limited application, and secondary pollutants, and achieve no secondary pollution, good biocompatibility, and good adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

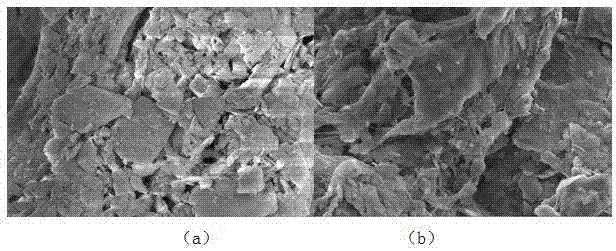

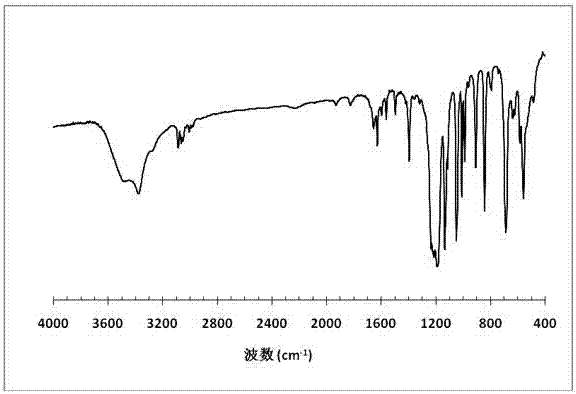

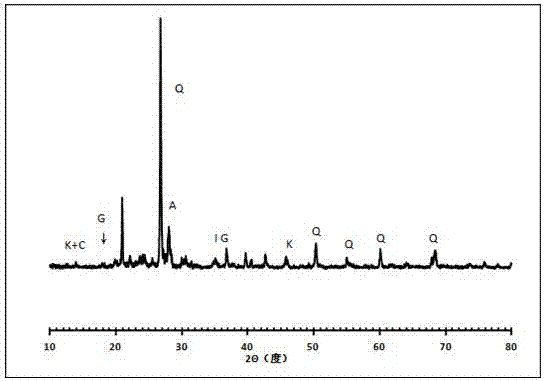

Method used

Image

Examples

Embodiment 1

[0036] (1) Acidification of loess particles: Take a certain amount of loess particles, disperse them into HCl solution with a concentration of 5 mol / L, stir at 65°C for 3 hours, cool, filter, wash with distilled water until neutral, and dry in vacuum at 60°C for 12 hours, the acidified loess is obtained.

[0037] (2) Surface modification of loess particles: Take 1 g of acidified loess particles, disperse them in 10 mL of anhydrous ethanol-water (volume ratio of ethanol to water: 3:1), and stir for 30 minutes at room temperature; Adjust the pH of the system to 2.0 with glacial acetic acid, then add 0.5 g of KH-570, and stir for 30 minutes; then adjust the pH of the system to 9.0 with ammonia water, raise the temperature to 60°C, and stir for 5 hours to complete the reaction. The product is filtered and washed with ethanol Three times, vacuum drying at 60° C. for 5 hours to obtain surface-modified loess particles.

[0038] (3) Preparation of graft copolymer: 1 g of surface-modifi...

Embodiment 2

[0041] (1) Acidification of loess particles: Take a certain amount of loess particles, disperse them into HCl solution with a concentration of 3 mol / L, stir at 50°C for 5 hours, cool, filter, wash with distilled water until neutral, and dry in vacuum at 50°C for 24 hours. hours, the acidified loess is obtained.

[0042] (2) Surface modification of loess particles: Take 10 g of acidified loess particles, disperse them in 100 mL of ethanol-water (4:1 volume ratio of ethanol to water) mixed solution, stir and disperse at room temperature for 30 minutes; Adjust the pH of the system to 3.5, add 2.0 g KH-171, and stir for 30 minutes; then adjust the pH of the system to 10 with ammonia water, raise the temperature to 85°C, and stir for 3 hours to complete the reaction. Dry under vacuum for 3 hours to obtain surface-modified loess particles.

[0043] (3) Preparation of graft copolymer: Add 2.5 g of surface-modified loess particles to 30 mL of 1,4-dioxane, stir well at room temperatur...

Embodiment 3

[0046] (1) Acidification of loess particles: Take a certain amount of loess particles, disperse them into HCl solution with a concentration of 1 mol / L, stir at 80°C for 1 hour, cool, filter, wash with distilled water until neutral, and dry in vacuum at 60°C for 36 hours, the acidified loess is obtained.

[0047] (2) Surface modification of loess particles: Take 15 g of acidified loess particles, disperse them in 150 mL of ethanol-water (volume ratio of ethanol to water: 5:1), and stir for 30 minutes at room temperature. Adjust the pH of the system to 5.0 with glacial acetic acid, add 5.0 g of KH-171, and stir for 40 minutes. Then the pH of the system was adjusted to 11.0 with ammonia water, the temperature was raised to 60°C, and the reaction was fully stirred for 5 hours to complete the reaction. The product was suction filtered, washed with ethanol three times, and vacuum-dried at 30°C for 5 hours to obtain surface-modified loess particles.

[0048] (3) Preparation of graft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com