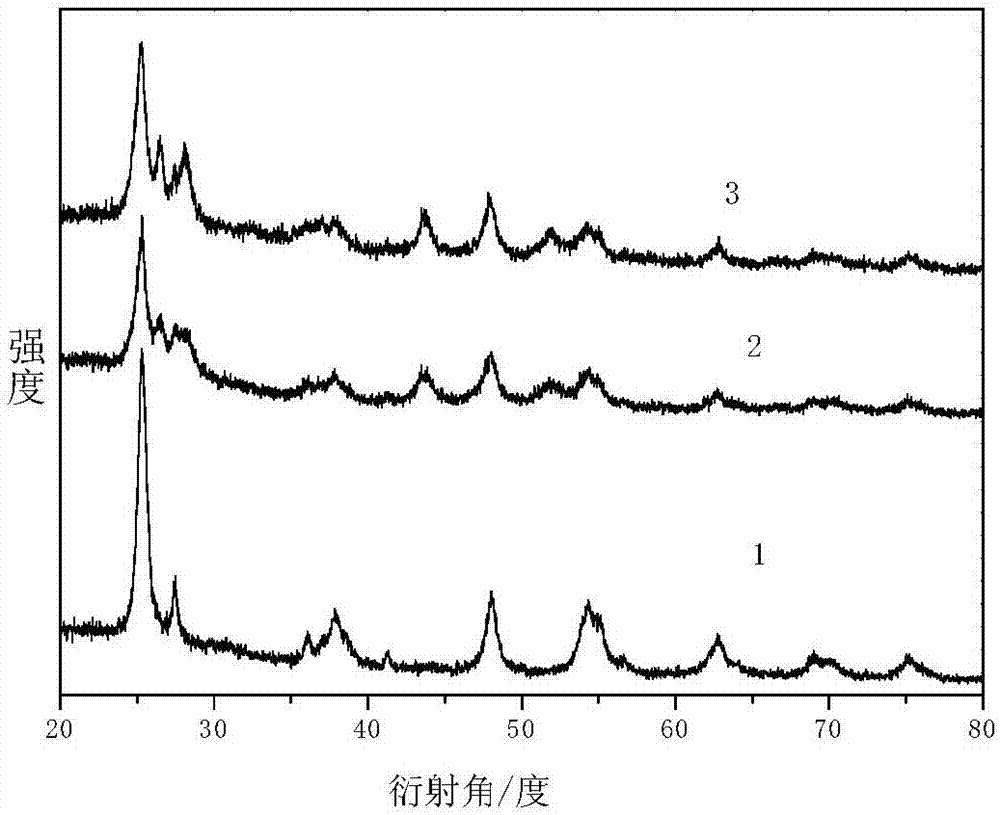

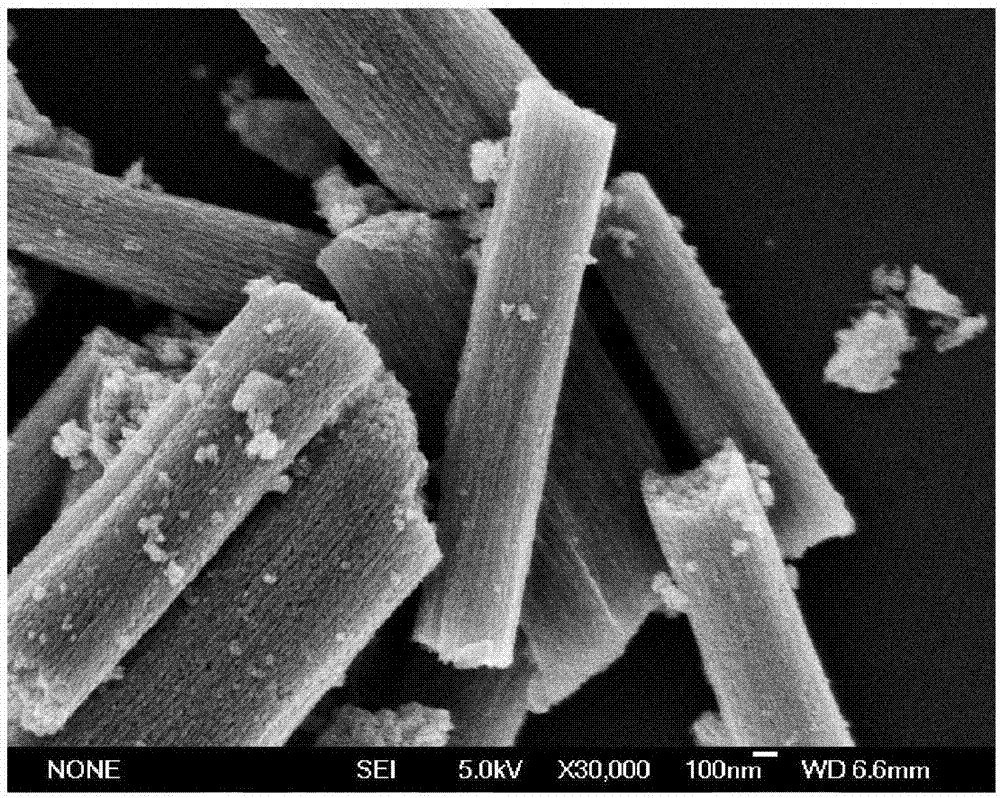

TiO2 fiber supporting CdS and MoS2 and preparation method thereof

A technology of titanium dioxide and molybdenum disulfide, applied in the field of photocatalysis, can solve the problems of easy recombination of photogenerated electrons and holes, low utilization rate of sunlight, etc., and achieve excellent photocatalytic activity, high photocatalytic efficiency, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method steps of the present embodiment are:

[0032] (1) Dissolve 4 mL of n-butyl titanate, 2 mL of acetylacetone, and 0.8 g of PVP into 10 mL of absolute ethanol, and stir evenly to obtain a precursor sol;

[0033] (2) inject an appropriate amount of sol obtained in step (1) into the liquid supply device (syringe), the distance between the nozzle tip and the receiving plate is 15 cm, and a voltage of 12 kV is applied to obtain a fiber film;

[0034] (3) Dry the fiber film obtained in step (2) at a low temperature of less than 45°C for 12 hours, then place it in a tube furnace, heat up at 1°C / min, take it out after keeping it warm at 450°C for 5 hours, and grind it to obtain TiO 2 fiber;

[0035] (4) Take 100 mg of the titanium dioxide fiber obtained in step (3), disperse it in 20 mL of pure water with 77.5 mg of cadmium nitrate, and 90 mg of cysteine, and transfer it to a 30 mL reaction kettle after stirring;

[0036] (5) heat preservation in an oven...

Embodiment 2

[0040] The preparation method steps of the present embodiment are:

[0041] (1) Dissolve 4 mL of n-butyl titanate, 2 mL of acetylacetone, and 0.8 g of PVP into 10 mL of absolute ethanol, and stir evenly to obtain a precursor sol;

[0042] (2) inject an appropriate amount of sol obtained in step (1) into the liquid supply device (syringe), the distance between the nozzle tip and the receiving plate is 15 cm, and a voltage of 12 kV is applied to obtain a fiber film;

[0043] (3) Dry the fiber film obtained in step (2) at a low temperature of less than 45°C for 12 hours, then place it in a tube furnace, heat up at 1°C / min, take it out after keeping it warm at 450°C for 5 hours, and grind it to obtain TiO2 fiber;

[0044] (4) 100 mg of the titanium dioxide fiber obtained in step (3) was dispersed in 20 mL of pure water with 62 mg of cadmium nitrate and 72 mg of cysteine, stirred evenly and then transferred to a 30 mL reactor;

[0045] (5) heat preservation in an oven at 120 degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com