Method of quickly and continuously preparing benzenediol from low-concentration water solution of phenol

An aqueous solution and hydroquinone technology, applied in the design and preparation of copper-based quaternary hydrotalcites, can solve the problems of short process flow, many influencing factors, and weak catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

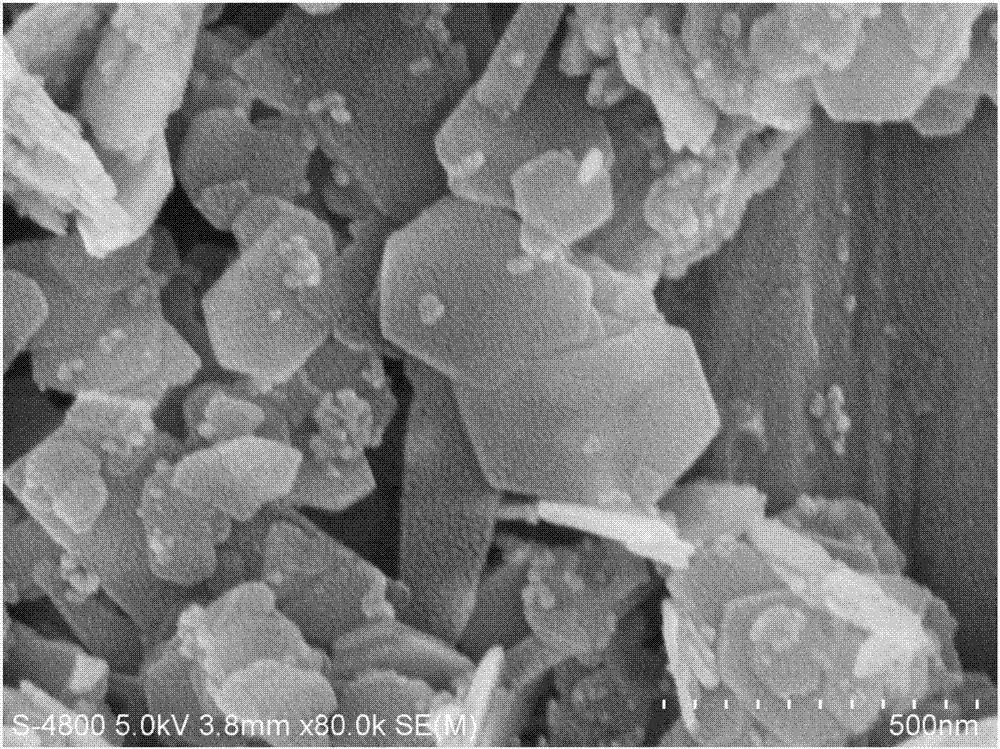

[0037] Prepare 150mL NaOH alkali solution with a molar concentration of 1mol / L, which is recorded as A solution. 0.024mol Cu(NO 3 ) 2 ·3H 2 O, 0.036Zn (NO 3 ) 2 ·6H 2 O and 0.005mol Fe(NO 3 ) 3 9H 2 O, 0.015mol Al(NO 3 ) 3 9H 2 O was dissolved in 150 mL deionized water, and treated under ultrasonic conditions for 5 min to obtain a clear solution, which was designated as solution B. Drop A solution and B solution into a 500mL four-necked flask at the same time, and use N 2 Protected and accompanied by mechanical stirring, control the pH of the system between 9-10, and finally keep the pH of the system at 10, dynamically crystallize in an oil bath at 60°C for 6h, and then microwave crystallize for 15min (keep the temperature at 60°C, microwave The power is controlled at 700W), centrifuged, and dried at 60° C. for 24 hours to obtain a gray-black powder, which is a copper-based quaternary nano-hydrotalcite catalyst.

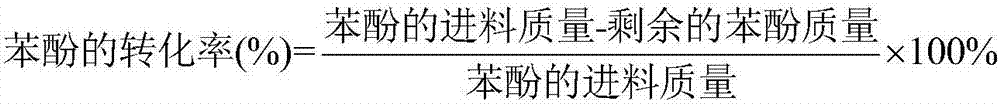

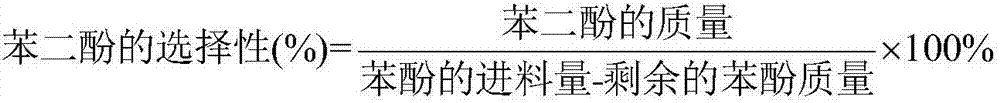

[0038] The continuous production of phenol hydroxy...

Embodiment 2

[0040] Using the catalyst prepared in Example 1, the continuous production of phenol hydroxylation was carried out in a tubular reactor with a reaction tube length of 10 meters and an inner diameter of 100 mm. Put phenol, water, 15% hydrogen peroxide, and copper-based quaternary nano-hydrotalcite catalysts into the reaction tube at flow rates of 15kg / h, 400kg / h, 100kg / h, and 1kg / h respectively, and adjust the water temperature in the jacketed tube to maintain 45°C, keep the reaction time for 15 minutes, and run continuously for 24 hours.

Embodiment 3

[0042] Except for the following steps, the rest are the same as in Example 2, and the water temperature in the jacketed tube is adjusted to maintain 48° C. for continuous production of phenol hydroxylation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com