Method for nickel-assisted low-temperature synthesis of molybdenum carbide electrocatalyst

An electrocatalyst, molybdenum carbide technology, applied in physical/chemical process catalysts, chemical instruments and methods, carbides, etc., to achieve the effects of good social and economic benefits, simple synthesis process, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

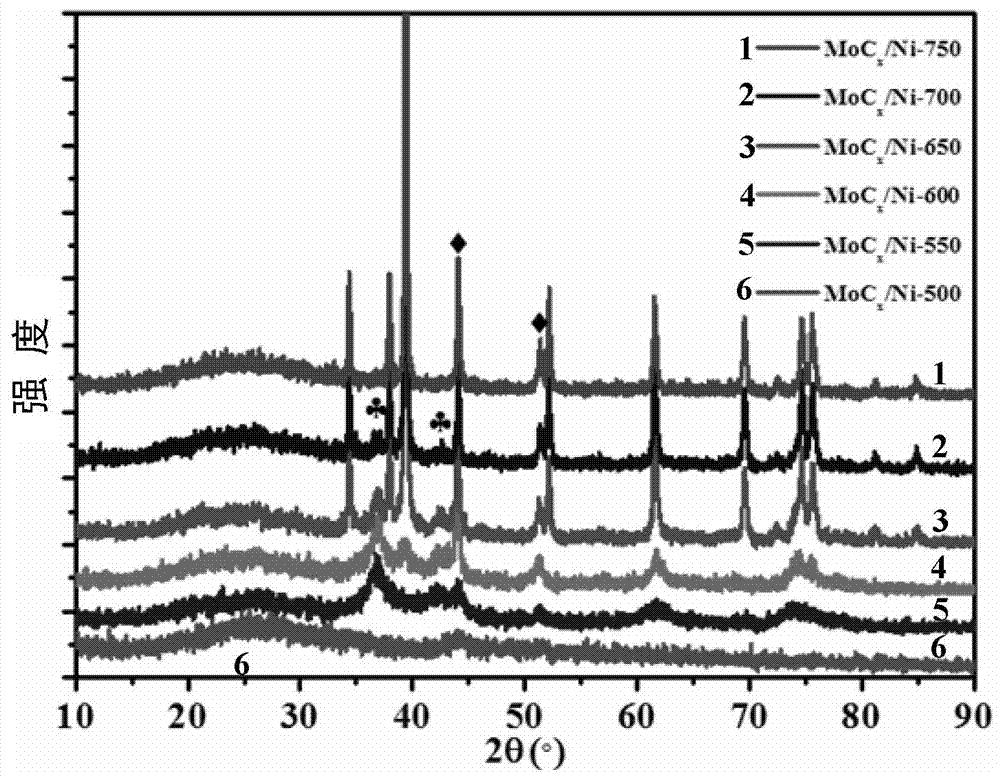

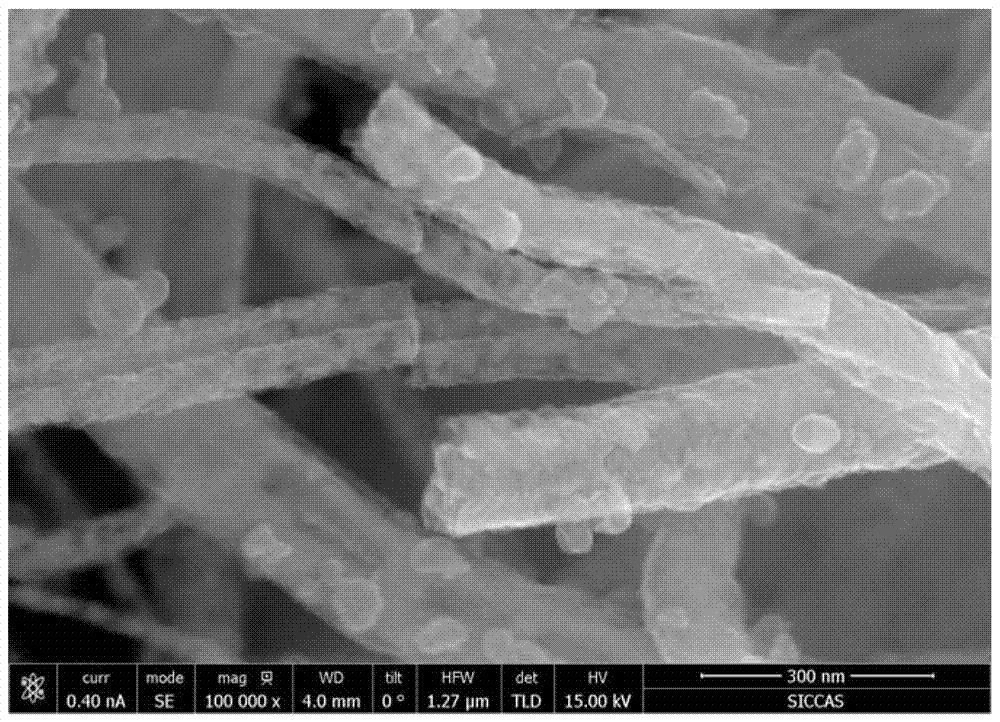

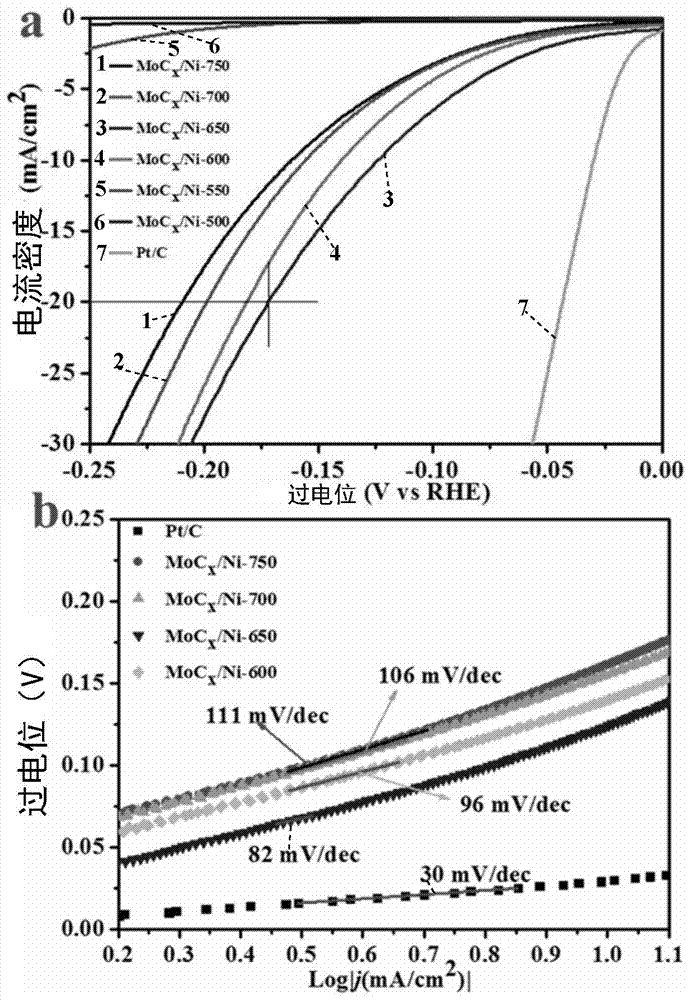

Embodiment 1

[0036] Choose 2-methylimidazole as the reducing carbon source, weigh 2-methylimidazole 1g, and ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 .4H 2 O) 0.5g, NiCl 2 .6H 2 O 0.22g in a beaker, add 20mL of water, ultrasonically dissolve, stir at room temperature (25°C) for 24h, wash the light green product with water, centrifuge, and dry. The dried product was calcined to 650° C. under Ar atmosphere, kept for 4 h, and then the calcined product was treated with dilute acid (specifically, 0.5M H 2 SO 4 solution acid) soaked for 24 hours to remove unstable species in the catalyst, and finally centrifuged and washed to neutrality, then dried, and the resulting product was recorded as MoC x / Ni-650.

[0037] The electrochemical test of the electrolysis of water to produce hydrogen by the nickel-assisted molybdenum carbide catalyst was carried out in the following steps:

[0038] First, weigh 4mg of the above catalyst and disperse it in a mixed solution containing 1mL of absolut...

Embodiment 2

[0040] The preparation process and steps in Example 2 are basically the same as those in Example 1 above, except that the selected calcination temperature is 500°C, and the prepared catalyst is denoted as MoC x / Ni-500. The catalytic performance of the catalyst for hydrogen production by electrolysis of water is the same as in Example 1.

Embodiment 3

[0042] Preparation process and steps in embodiment 3 are basically the same as above-mentioned embodiment 1, and difference is: the selected calcination temperature is 550 ℃, and the catalyst prepared is denoted as MoC x / Ni-550. The catalytic performance of the catalyst for hydrogen production by electrolysis of water is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com