Preparation method for negative electrode material with core-shell coated structure and for lithium ion battery

A lithium-ion battery and coating structure technology, applied in the field of nanomaterials and new energy materials, can solve the problems of unsuppressed volume expansion, many graphene defects, and shedding of active materials, and achieves low cost, excellent mechanical properties, The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

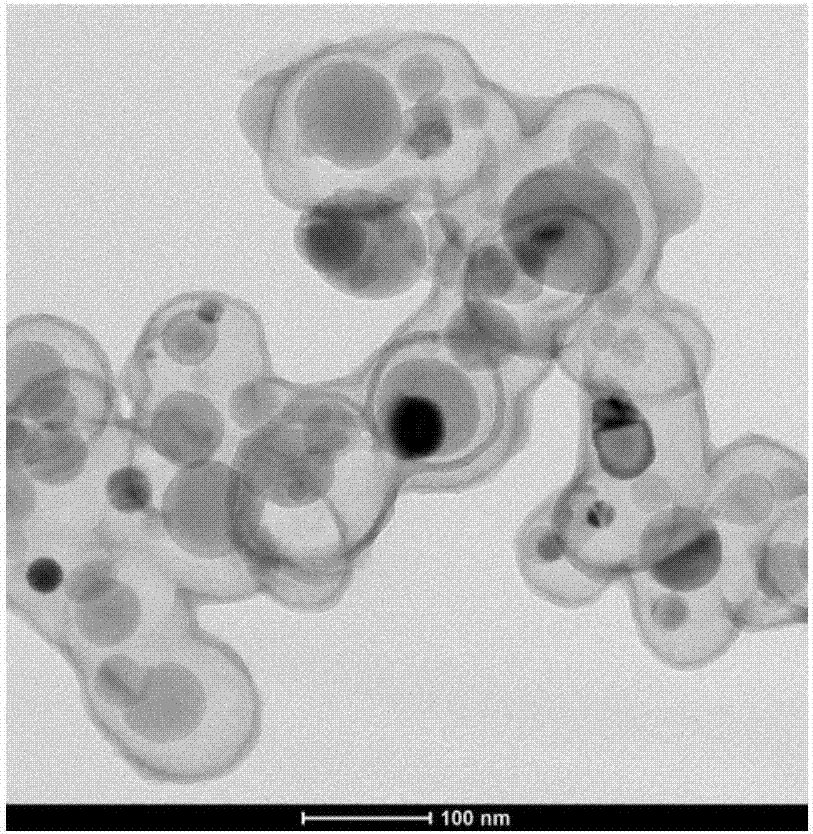

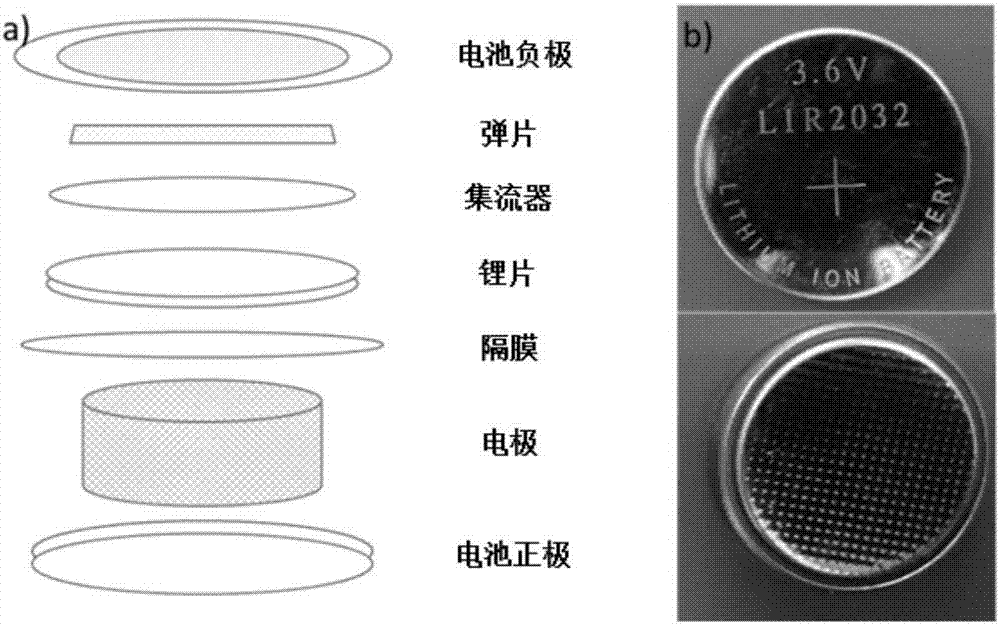

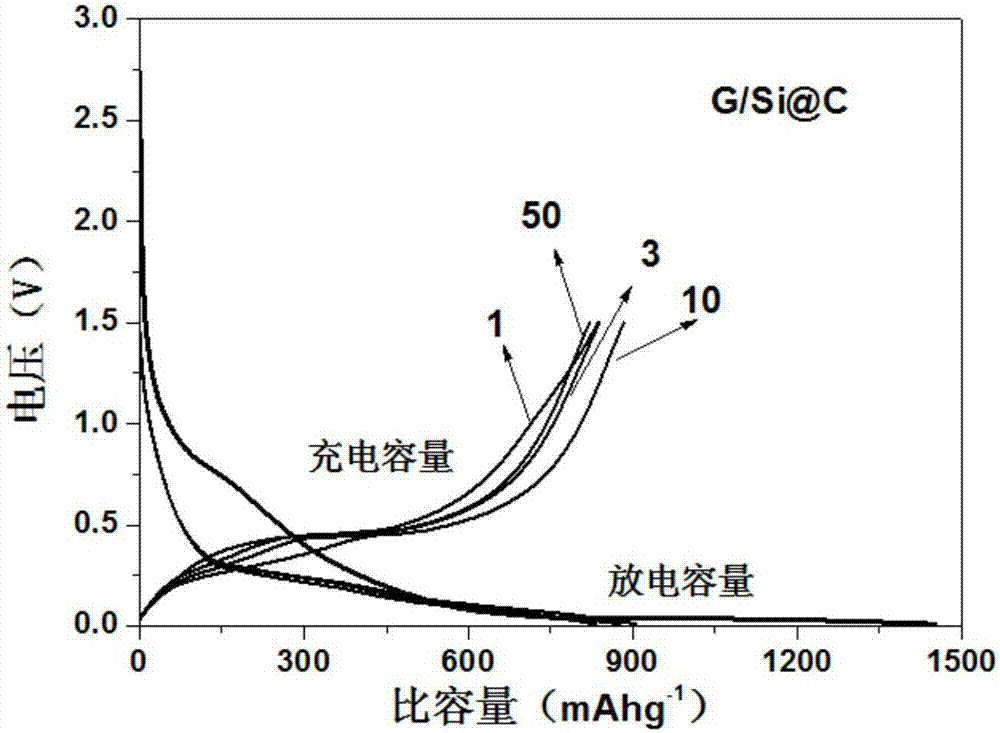

[0026] Take 160mL of absolute ethanol and 40mL of deionized water, weigh 200mg of nano-silicon powder and add it to the water-ethanol mixed solution, seal it and sonicate for 2h, add 2mL of concentrated ammonia water and 1mL of ethyl orthosilicate to the solution, and stir magnetically for 8-10h. Centrifuge three times, the cleaning solution is a mixture of ethanol and water with a volume ratio of 1:1, and then dry at a constant temperature at 80°C for 8 hours; take 400 mg of the sample and dissolve it in 160 mL of deionized water, add 193.8 mg of Tris buffer, ultrasonicate for 2 hours, add 400 mg of dopamine hydrochloride, and stir React for 24 hours, centrifuge three times with deionized water, dry at 80°C for 8 hours, and calcine the sample in an argon atmosphere to carbonize the organic matter on the surface, keep at 700°C for 2 hours, and the heating rate is 3°C / min, and wait for natural cooling ; The sample was ultrasonically dispersed in deionized water, then dropped int...

Embodiment 2

[0031] Add 150 mg of graphene oxide (GO) to 75 mL of deionized water to make 2 mg / mL, add 150 mg of carbon-coated silicon to 75 mL of deionized water to make 2 mg / mL, ultrasonically disperse for 2 hours, and mix the two solutions with magnetic stirring for 4 hours to disperse Suction filter after uniformity, take it out after about 1.5h, put the obtained film into the dryer for 12h to dry, and obtain the GO / Si@C composite material, heat the obtained product to 700°C in a vacuum heat treatment furnace, and keep it warm 120min, the air pressure is 50Pa. That is, the r-GO / Si@C composite material was obtained, and it was prepared as a lithium-ion battery anode material, and the first charge and discharge capacity was 630.5mAh g -1 and 1162.1mAh·g -1 , 553.8mAh·g after 100 cycles -1 and 560.5mAh·g -1 , the initial capacity is low, but the cycle stability is better, and the capacity retention rate reaches 87.8%.

Embodiment 3

[0033] Add 200mg of graphene oxide (GO) to 100mL deionized water to make 2mg / mL, add 100mg of carbon-coated silicon to 50mL deionized water to make 2mg / mL, and ultrasonically disperse for 2 hours. Stir the two solutions for 6 hours to disperse evenly Suction filtration in a vacuum water pump, take it out after about 2.5h, put the obtained film into a dryer for 12h drying treatment, and obtain a GO / Si@C composite material, heat the obtained product to 700°C in a vacuum heat treatment furnace , keep warm for 120min, and the air pressure is 50Pa. That is, the r-GO / Si@C composite material was obtained, and it was prepared as a negative electrode material for lithium-ion batteries. The first charge and discharge capacities were 259.5mAh g -1 and 734.3mAh·g -1 , 289.5mAh·g after 100 cycles -1 and 291.5mAh·g -1 , although the capacity is too low, but the cycle stability is very good, almost no loss of capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

| Coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com