Method for preparing nanometer liposome by using supergravity technology

A nano-liposome and supergravity technology, which is applied in the fields of biomedicine and cosmetics, can solve the problems of difficult industrial production of nano-liposomes, narrow particle size distribution of nano-liposomes, and short production time, so as to avoid rupture and aggregation, Low-cost, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

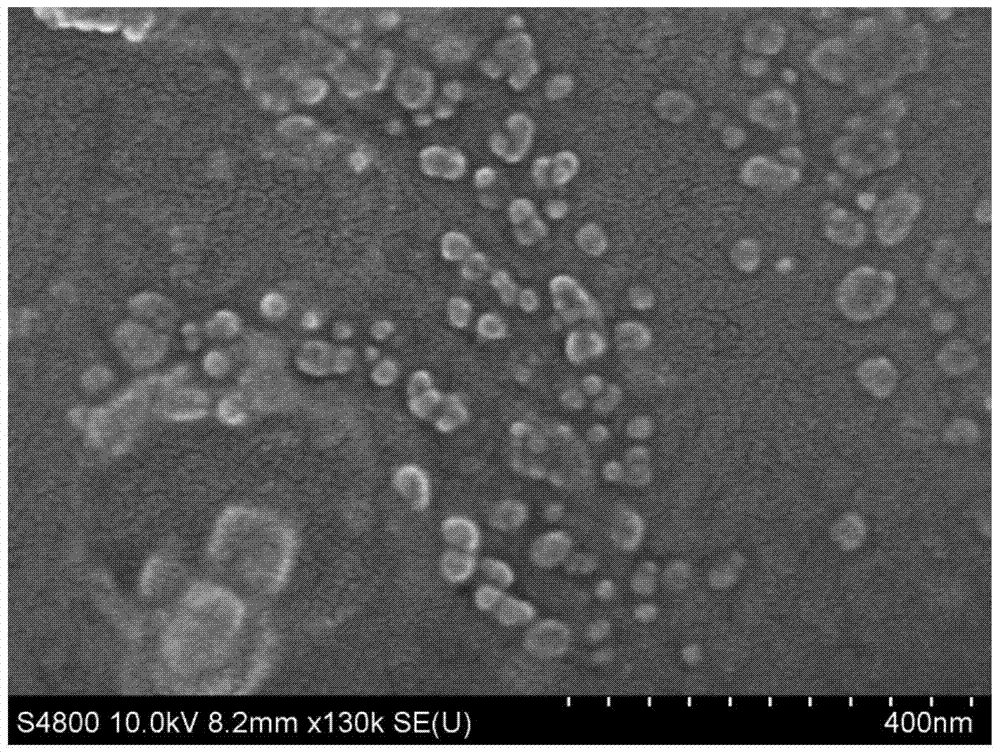

[0037] Dissolve 80g of phosphatidylcholine and 10g of cholesterol in 2L of ethanol, add 5g of potassium dihydrogen phosphate and 5g of dipotassium hydrogen phosphate into 20L of water and adjust the pH to 6.5, turn on the high-gravity rotating bed and adjust the speed to 2000rpm, and use 2ml of ethanol / min, the water phase is fed at 20ml / min, and the temperature of the control system is 30°C. After the ethanol phase is fed, the high-gravity rotary bed is closed, and 300g sucrose is added to the resulting mixed solution, and the organic solvent is removed after freeze-drying. A dry freeze-dried powder is obtained. The freeze-dried powder can be stored for a long time, and the dried freeze-dried powder is reconstituted and hydrated with pure water before use to obtain a nanoliposome solution. figure 1 A scanning electron micrograph of the nanoliposome prepared in Example 1 of the present invention is shown. It can be seen from the figure that the average particle size of the n...

Embodiment 2

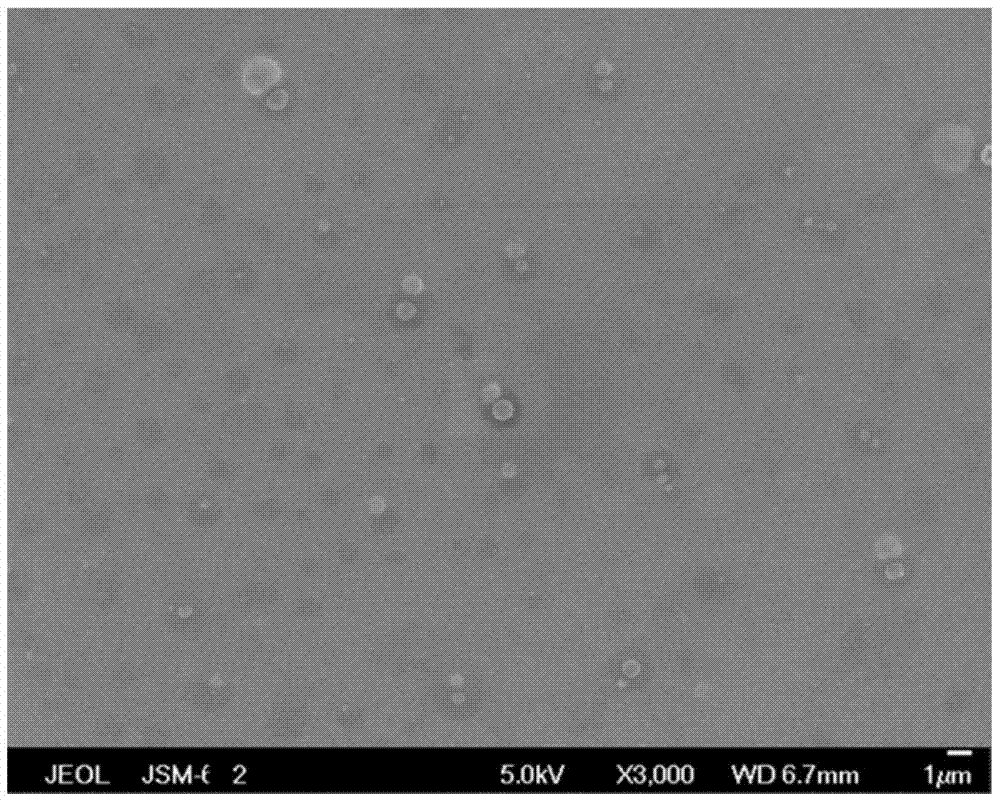

[0041] Dissolve 70g of phosphatidylcholine and 10g of cholesterol in 2L of isopropanol solution, dissolve 4g of potassium dihydrogen phosphate and 6g of disodium hydrogen phosphate in 20L of water, adjust the pH of the buffer to 7.4, and turn on the high-gravity rotating bed to adjust the speed to 2000rpm. The isopropanol phase is fed at 3ml / min, the water phase at 30ml / min, and the temperature of the control system is 30°C. After the isopropanol phase is fed, the supergravity rotary bed is closed, and 300g of sucrose is added to the resulting mixed solution. After freeze-drying, the solvent is removed to obtain dry nano-liposome freeze-dried powder. The freeze-dried powder can be stored for a long time, and the dried freeze-dried powder is reconstituted and hydrated with pure water before use to obtain a nanoliposome solution. The average particle diameter of the nanoliposome is 80nm, and its particle size distribution test shows that its PDI value is 0.16, showing good dispe...

Embodiment 3

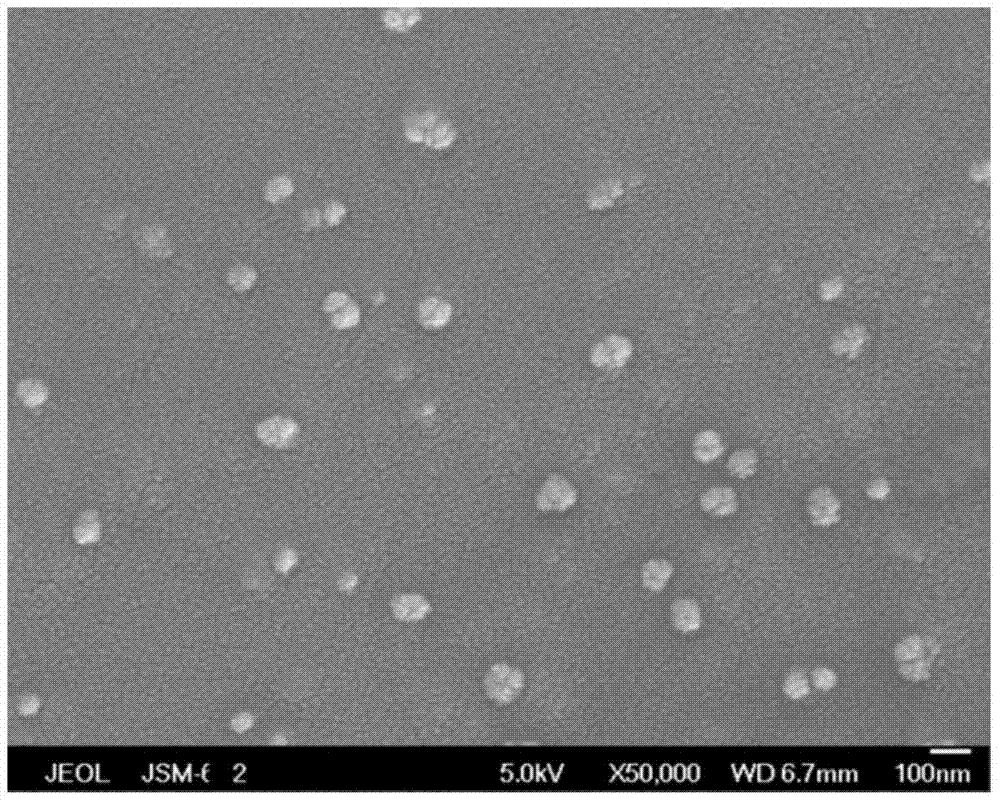

[0043] Dissolve 70g of phosphatidylcholine and 15g of cholesterol in 2L of tert-butanol solution, dissolve 3g of disodium hydrogen phosphate and 2g of phosphoric acid in 10L of water and adjust the pH of the buffer to 5, turn on the supergravity rotating bed and adjust the speed to 1000rpm, t The butanol phase is fed at 3ml / min, the water phase is fed at 30ml / min, and the temperature of the system is controlled at 30°C. After the organic solution is fed, the high-gravity rotating bed is closed, and 300g trehalose is added to the resulting mixed solution. After drying, the solvent is removed to obtain dry nanoliposome freeze-dried powder. The freeze-dried powder can be stored for a long time, and the dried freeze-dried powder is reconstituted and hydrated with pure water before use to obtain a nanoliposome solution. The average particle diameter of the nanoliposome is 65nm, and its particle size distribution test shows that its PDI value is 0.2, showing good dispersion stabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com