Method for removing total nitrogen in water by nanometer zero-valent iron combined ion exchange resin and use thereof

A technology of ion exchange resin and nanometer zero-valent iron, applied in the direction of ion exchange water/sewage treatment, chemical instruments and methods, water pollutants, etc., can solve problems such as secondary pollution of water bodies, and achieve effective removal and removal of ammonia nitrogen pollution, The effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Preparation method of material S-NZVI, the steps are:

[0039] 1) Take 5ml waste acid (90.86g / L iron content) and 100ml ethanol solution and add to the triangular conical flask

[0040] Medium, stir for a period of time on a magnetic stirrer;

[0041] 2) Blow in nitrogen to remove oxygen, add a certain quality of sodium borohydride, and place the solution on the magnetic plate after the reaction

[0042] Precipitate, wash with water and ethanol three times successively, put into a vacuum drying box and ventilate nitrogen, temperature 80℃,

[0043] After drying for 8 hours, it is opened after cooling, and ground into powder, and put in a vacuum bag for use.

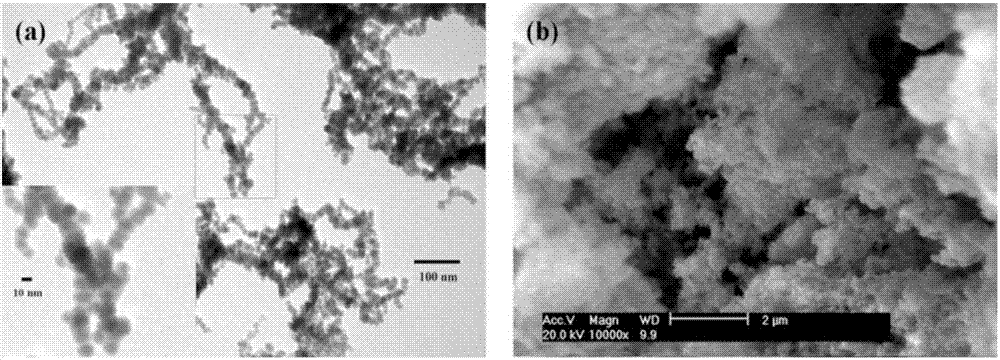

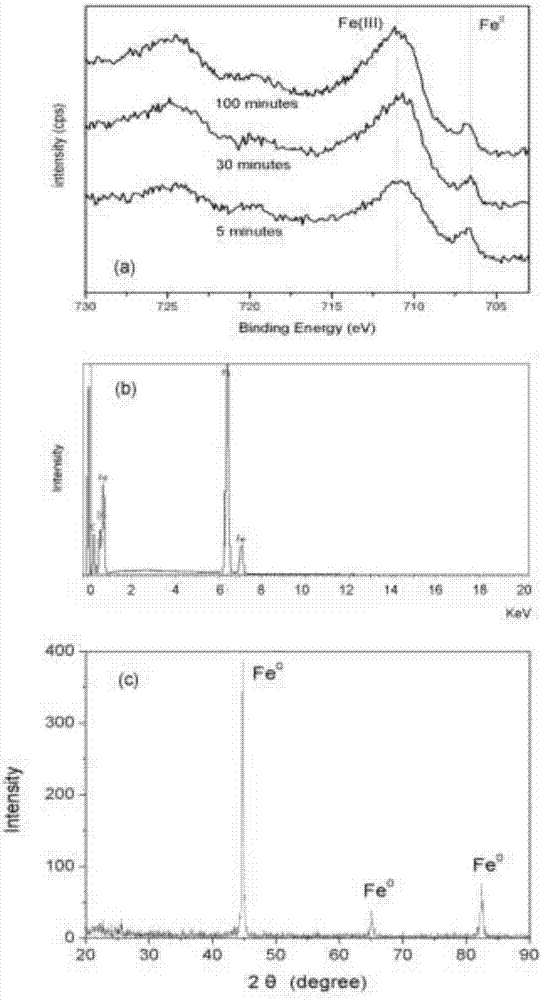

[0044] figure 1 TEM and SEM images of the material S-NZVI prepared in Example 1. by figure 1 It can be seen that the particle size of the nano metal particles is basically in the range of 20-40 nm, and the appearance is spherical. It can be seen from the transmission electron microscope image that the black nano-m...

Embodiment 2

[0046] Example 2: The effect of the dosage of material S-NZVI on the removal rate of nitrate nitrogen, the steps are:

[0047] 1) Take 50mL potassium nitrate solution into a 100mL Erlenmeyer flask, respectively take 0.04g, 0.06g, 0.08g, 0.12g, 0.14g, 0.16g material S-NZVI into the Erlenmeyer flask;

[0048] 2) The mixture is reacted in a shaker for 4 hours at a temperature of 28±1°C and a speed of 200r / min. Separate the reacted solution magnetically, pass a 0.45 micron filter membrane, and detect the concentration of nitrate in the mixed solution by ultraviolet spectrophotometry.

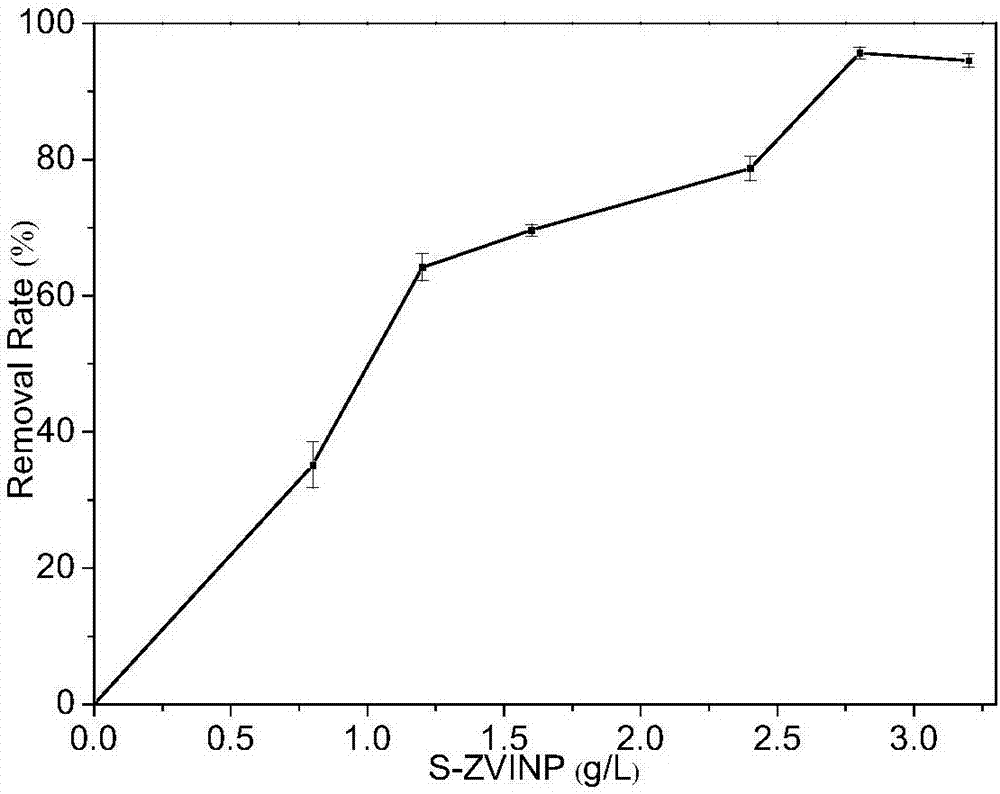

[0049] Under the condition of nitrate nitrogen concentration of 20mg / L, dosing different amounts of nano-zero-valent iron on its removal rate is shown in the experimental results image 3 . When the reaction time is 4h, when the dosage of S-NZVI is 0.8g / L, the removal rate of nitrate nitrogen is 35.19%. When the dosage is 1.2g / L, the removal rate is 64.18%. When the dosage of S-NZVI is 2.8g / L, the remov...

Embodiment 3

[0050] Example 3: The effect of different pH values on the removal of nitrate and total nitrogen from S-NZVI, the steps are:

[0051] 1) Take 50mL potassium nitrate solution into a 100mL Erlenmeyer flask, adjust the pH of the solution to 3, 5, 7, 9, and 11 respectively, and add 0.14g of material S-NZVI into the solution;

[0052] 2) The mixture is reacted in a shaker for 4 hours at a temperature of 28±1°C and a speed of 200r / min. Separate the reacted solution magnetically, pass a 0.45 micron filter membrane, and detect the concentration of nitrate and total nitrogen in the mixed solution by ultraviolet spectrophotometry.

[0053] Figure 4 It is the effect of different pH values on the removal of nitrate from the material S-NZVI. The removal effect is not high when the initial pH value is too acidic or too basic, and the removal rate is 99% in the acidic environment, that is, the initial pH=5. Because in the heterogeneous reaction, nanomaterials first capture NO by adsorption 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com