New process for one-step synthesis of crotonaldehyde from acetaldehyde, and solid catalyst thereof

A technology of solid catalyst and crotonaldehyde, applied in molecular sieve catalysts, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of complex structure of condensation tower, unfavorable industrial production, and shortened service life and other issues, to achieve the effects of catalyst cost reduction, energy saving, and reduction of steam and electric energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

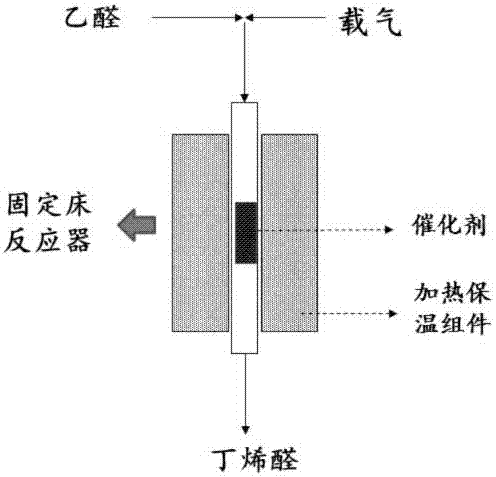

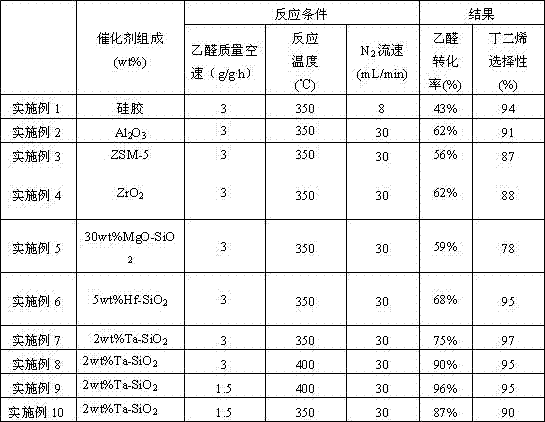

[0028] Example 1: 1 g of silica gel catalyst was loaded into an 8 mm×400 mm quartz glass tube fixed-bed reactor, and the temperature was raised to 350° C. for half an hour under N2 purging at a flow rate of 10 mL / min. Next, acetaldehyde enters the reactor at a mass space velocity of 2 g / g·h for catalytic reaction. At the outlet of the reactor, the conversion of acetaldehyde was 43%, and the selectivity of crotonaldehyde was 94%. The specific experimental results are shown in Table 1.

Embodiment 2

[0030] The difference between embodiment 2 and embodiment 1 is that the catalyst is Al2O3 catalyst, and all the other reaction conditions are the same as embodiment 1. The specific experimental results are shown in Table 1.

Embodiment 3

[0032] The difference between Example 3 and Example 1 is that the catalyst is a ZSM-5 silica-alumina molecular sieve catalyst, and the rest of the reaction conditions are the same as in Example 1. The specific experimental results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com