Essence microcapsule and preparation method thereof

A technology of essence microcapsules and essences, applied in the directions of microcapsule preparations, microsphere preparation, essential oils/flavors, etc., can solve the problems of easy aggregation, product application effects, inability to effectively encapsulate and stably store, and achieve antibacterial Excellent effect, good versatility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

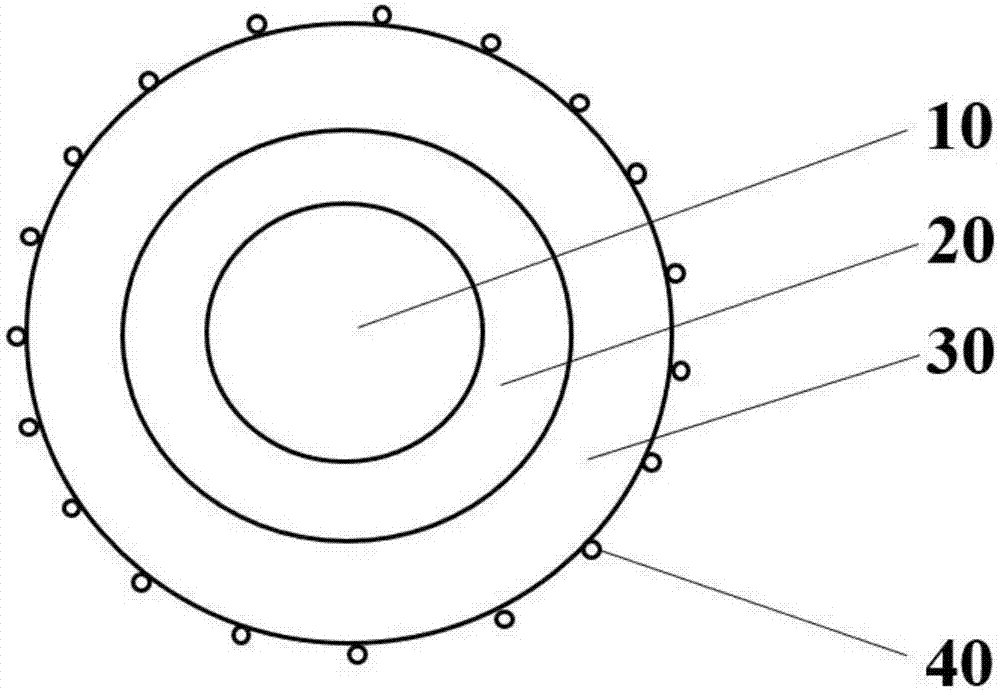

Image

Examples

preparation example Construction

[0031] The preparation method of above-mentioned essence microcapsule comprises the following steps:

[0032] 1) dissolving the polymer in an organic solvent, then adding the core material, and mixing evenly to obtain a mixed solution;

[0033] 2) Dissolve the colloidal protective agent in water, add the mixed solution in step 1) while stirring, raise the temperature to 10-15°C higher than the boiling point of the organic solvent, and keep it warm for 0.5-1 hour to obtain a polymer pre-coated core material ;

[0034] 3) adding wall materials, mixing evenly, aging at 60-70° C. for 3-5 hours, filtering, drying, spraying a solution containing antibacterial particles, and drying to obtain essence microcapsules.

[0035] Preferably, the mass ratio of the polymer and the organic solvent in step 1) is 1: (5-20).

[0036] Preferably, the organic solvent described in step 1) is at least one of dichloromethane, chloroform, petroleum ether, and tetrahydrofuran.

[0037] Preferably, th...

Embodiment 1

[0041] A preparation method of essence microcapsules comprises the following steps:

[0042] 1) Dissolve 1.0g polymethyl methacrylate in 20.0g dichloromethane, then add 1.0g rose essential oil, stir and mix evenly to obtain a mixed solution;

[0043] 2) Dissolve 0.5g of polyvinyl alcohol in 100.0g of distilled water, add the mixed solution in step 1) while stirring, raise the temperature to 55°C, and keep it warm for 1 hour to obtain a polymer pre-coated core material;

[0044] 3) Add 0.5g of sodium alginate, stir and mix evenly, mature at 60°C for 5 hours, filter, dry, spray a solution containing nano-silver particles (containing 0.002g of nano-silver particles), and dry to obtain essence microcapsules.

[0045] After testing, the average particle size of the essence microcapsules prepared in this example is 70 μm.

Embodiment 2

[0047] A preparation method of essence microcapsules comprises the following steps:

[0048] 1) Dissolve 0.5g polyacrylamide in 2.5g tetrahydrofuran, then add 1.0g lemon oil, stir and mix evenly to obtain a mixed solution;

[0049] 2) Dissolve 0.5g of sodium dodecylsulfonate in 50.0g of distilled water, add the mixed solution in step 1) while stirring, raise the temperature to 80°C, and keep it warm for 0.5 hours to obtain a polymer pre-coated core material;

[0050] 3) Add 1.0 g of polystyrene, stir and mix evenly, mature at 65°C for 4 hours, filter, dry, spray a solution containing nano-silver particles (containing 0.001 g of nano-silver particles), and dry to obtain essence microcapsules.

[0051] After testing, the average particle size of the essence microcapsules prepared in this example is 70 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com