ZnS/Bi2O3 heterojunction molecularly-imprinted photocatalytic membrane, preparation method and application

A technology of photocatalytic film and molecular imprinting, applied in chemical instruments and methods, physical/chemical process catalysts, water/sludge/sewage treatment, etc., can solve the problems of non-selectivity and difficult target removal, etc. Simple and convenient treatment, simple steps, and the effect of improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

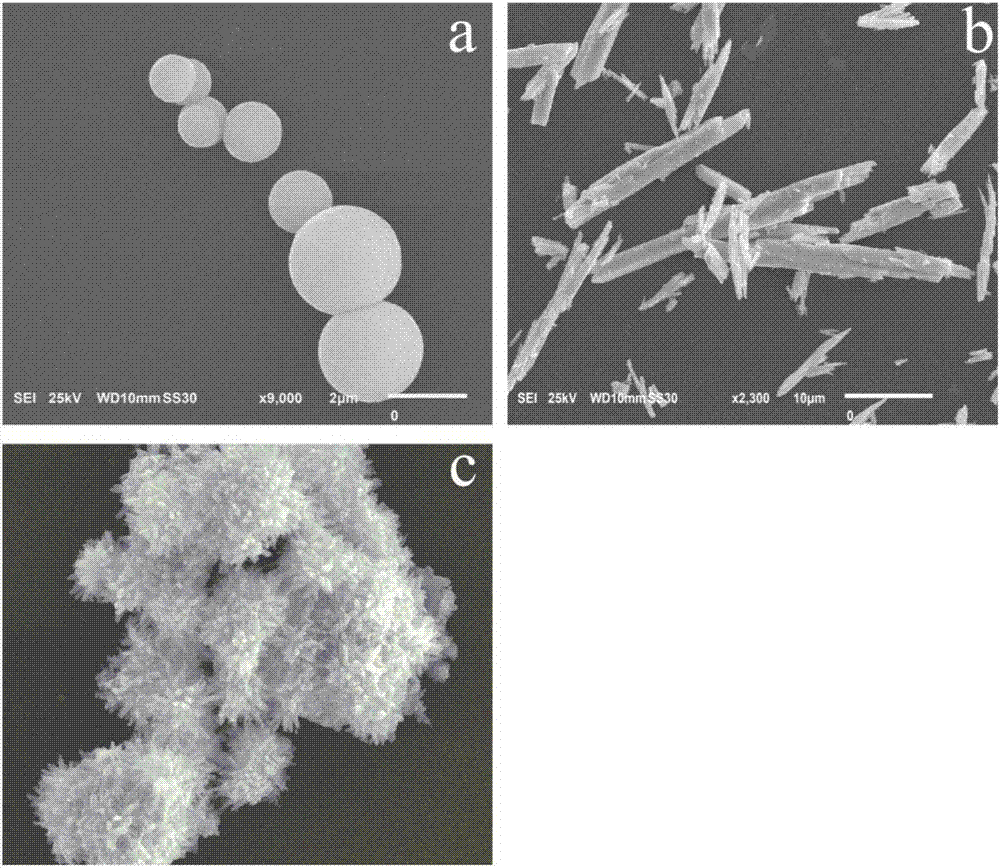

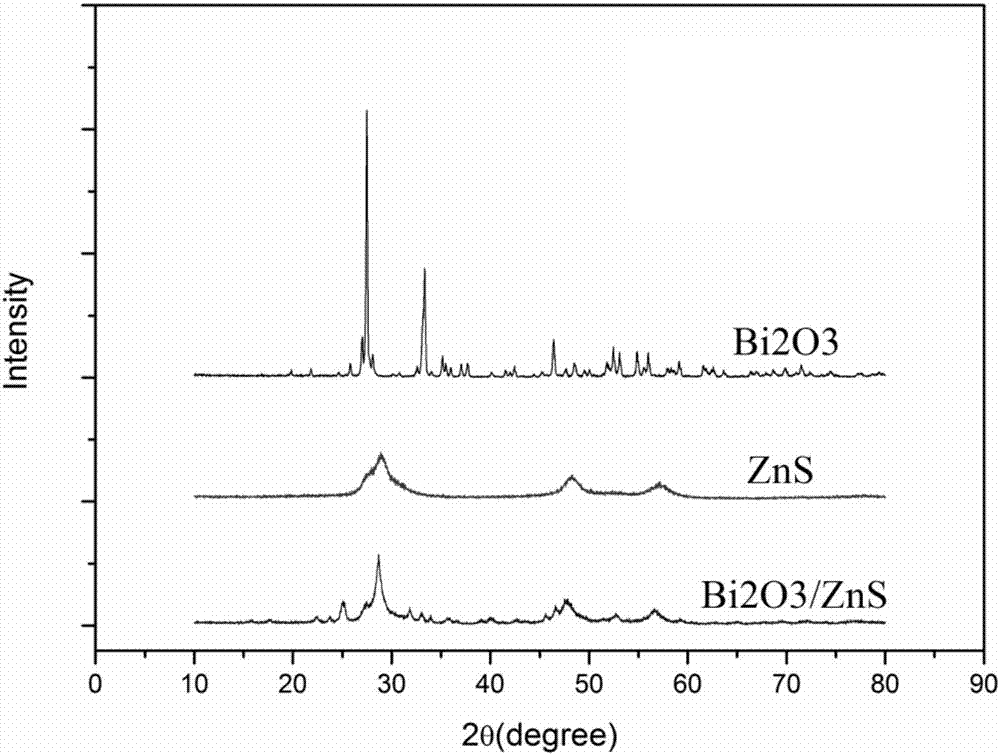

[0032] (1) ZnS / Bi 2 o 3 Preparation of heterojunction catalysts

[0033] First, dissolve 9.7g of bismuth nitrate pentahydrate in 100mL of deionized water to obtain a bismuth nitrate solution, and then take 500mL of 0.5mol·L -1 Add sodium hydroxide solution dropwise to bismuth nitrate solution, stir, and react at room temperature to obtain white or light yellow precipitate. Centrifuged, then washed three times with deionized water and absolute ethanol, dried at 60°C for 12 hours after centrifugal separation, put the above powder in a muffle furnace and calcined at 400°C for 2 hours to obtain Bi 2 o 3 Catalyst, for use. Dissolve 2.2g of zinc acetate dihydrate and 3.8g of thiourea in 70mL of deionized water, then take 0.2g of Bi 2 o 3 The photocatalyst was dispersed in the above solution. After standing still for 0.5h, the above solution was transferred to a stainless steel autoclave, heated at 170°C for 5h, and after cooling to room temperature, it was vacuum filtered with...

Embodiment 2

[0041] Under the condition that other conditions remain unchanged, the comparative experiment is established as follows: (1) Bi 2 o 3 For photocatalysts, the calcination temperature is 300°C, the calcination time is 4h, and ZnS / Bi is synthesized by hydrothermal method 2 o 3 For heterojunction photocatalysts, the reaction temperature of the reactor is 210°C, and the reaction time is 5 hours. After the reaction, wash and dry in the same way, and grind to obtain a powder catalyst for use. (2) Bi 2 o 3 For photocatalysts, the calcination temperature is 500°C, the calcination time is 6h, and ZnS / Bi is synthesized by hydrothermal method 2 o 3 For heterojunction photocatalysts, the reaction temperature of the reactor is 170°C, and the reaction time is 24 hours. After the reaction, wash and dry in the same way, and grind to obtain a powder catalyst for use. The obtained catalysts prepared under different conditions were used to degrade rhodamine B, and the degradation efficiency...

Embodiment 3

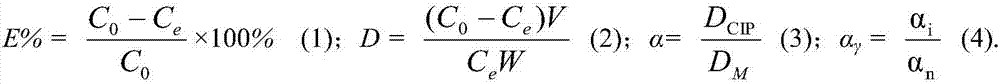

[0043] (1) By changing ZnS / Bi 2 o 3 The amount of heterojunction photocatalyst (0.2g, 0.3g, 0.4g) was used to examine the effect of catalyst dosage on photocatalytic degradation. 2 o 3 While changing the amount of heterojunction photocatalyst, change the amount of dimethyl sulfoxide (16.94g, 16.84g, 16.74g) to ensure that ZnS / Bi 2 o 3 The total mass fraction of the heterojunction photocatalyst and dimethyl sulfoxide is 85.7%. The results show that when the catalyst dosage is 0.4g, the degradation efficiency of rhodamine B is the highest, which can reach more than 90%. Therefore, the amount of catalyst selected in the experiment was 0.4 g.

[0044] (2) Molecularly imprinted catalytic membranes prepared with 0.4 g of photocatalysts were catalytically degraded under visible light at different concentrations (10, 20, 30, 40, 50 mg·L -1 ) Rhodamine B solution, the degradation kinetics of Rhodamine B by molecularly imprinted photocatalyst membranes at different concentrations w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com