A kind of quantum dot silk composite material and its preparation method

A technology of composite materials and quantum dots, which is applied in the field of quantum dot silk composite materials and its preparation, can solve the problems of destroying silk quality, low quantum yield, and serious application restrictions, and achieves wide application prospects, simple production process, and fluorescent rich color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

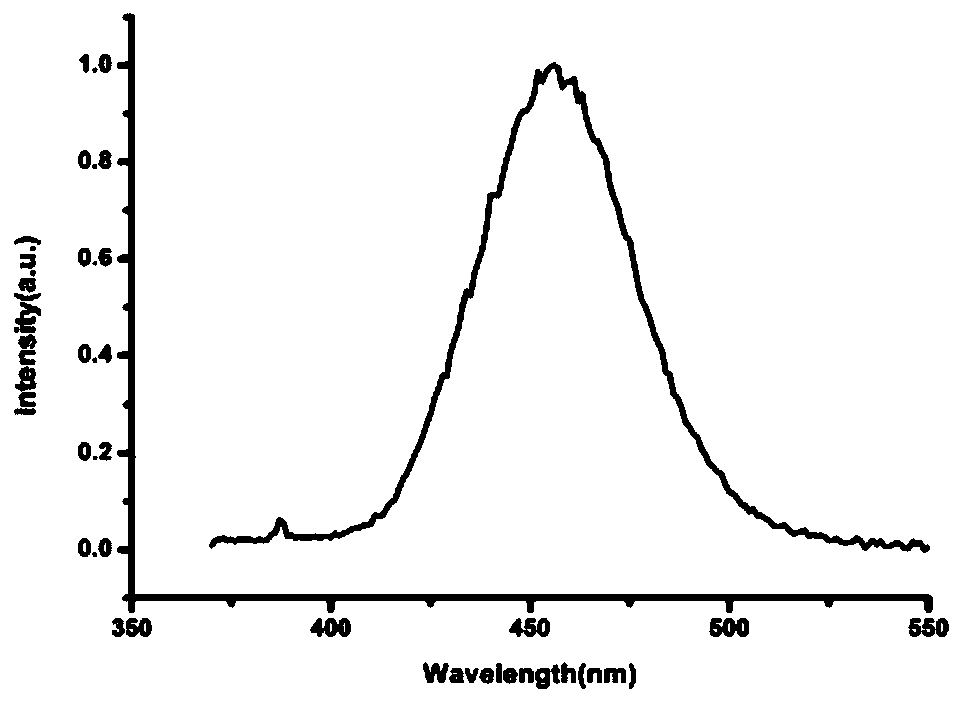

[0023] a. Synthesis of quantum dot luminescent materials

[0024] CdS / ZnS quantum dot nanomaterials were synthesized by high temperature injection method.

[0025] Take 0.0256g of cadmium oxide, 0.502g of oleic acid, and 6g of octadecene, stir and heat to 260°C under nitrogen, add 1mL of sulfur precursor solution (dissolve 0.032g of sulfur powder in 10mL of octadecene), and reduce the reaction solution to 240 ℃, maintain 10min, inject a certain amount of zinc diethyldithiocarbamate precursor solution (dissolve 0.362g zinc diethyldithiocarbamate in 10mL oleylamine solution), raise the temperature to 180℃, maintain 20min .

[0026] b. Surface treatment of quantum dot luminescent materials

[0027] Take the reacted quantum dot stock solution, add n-hexane-methanol mixed washing solution with a volume ratio of 1:2, wash the quantum dots, repeat several times, and finally obtain a quantum dot n-hexane solution containing a small amount of ligands.

[0028] c. Treatment of silk m...

Embodiment 2

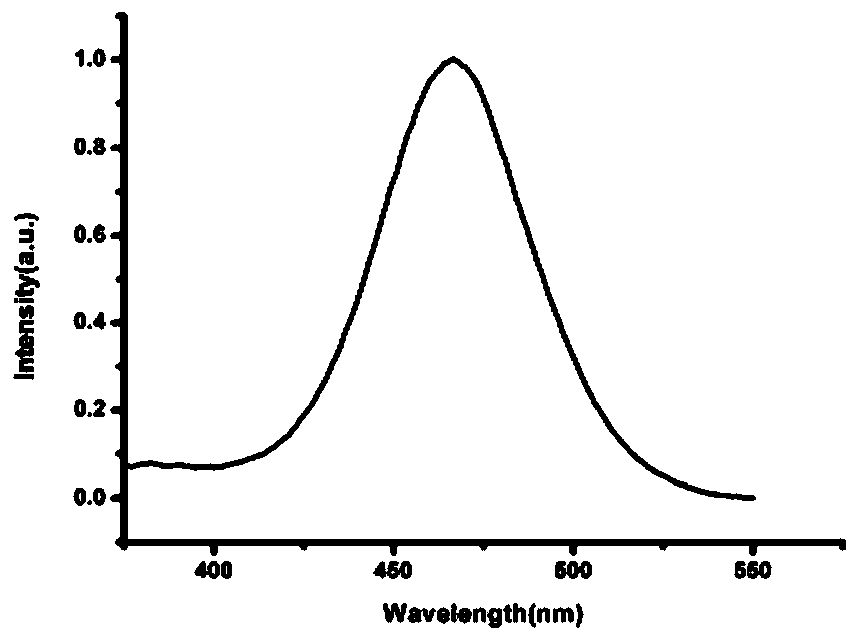

[0037] a. Synthesis of quantum dot luminescent materials

[0038] CdSe@ZnS / ZnS quantum dot nanomaterials were synthesized by high temperature implantation method. A mixed solution of 0.14 mmol of cadmium acetate, 3.41 mmol of zinc oxide and 7 mL of oleic acid was heated to 150° C. in a nitrogen atmosphere, and then 15 mL of octadecene was added, followed by heating to 310° C. Rapidly inject 2 mL of selenium-sulfur precursor solution (dissolve 5 mmol of selenium powder and 5 mmol of sulfur powder in 5 mL of tri-n-octylphosphine), and grow at 310 °C for 10 min. Then inject a mixed solution of 1.6mmol sulfur powder and 2.4mL octadecene, maintain 310°C for 12min, then inject zinc acetate precursor solution (dissolve 2.86mmol zinc acetate in 1mL oleic acid and 4mL octadecene) to reduce the temperature of the reaction solution After cooling down to 270°C, add a mixed solution of 9.65mmol sulfur powder and 5mL tri-n-octylphosphine, and grow at 270°C for 20min.

[0039] b. Surface t...

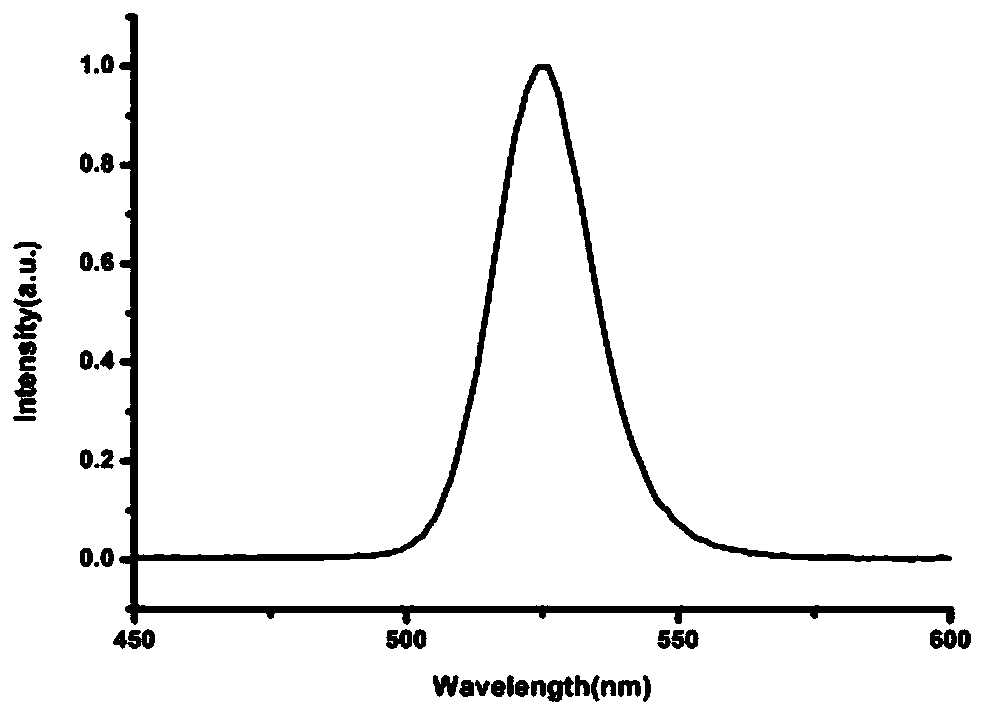

Embodiment 3

[0050] a. Synthesis of quantum dot luminescent materials

[0051] CdS / ZnS quantum dot nanomaterials were synthesized by high temperature injection method. Take 0.0256g of cadmium oxide, 0.502g of oleic acid, and 6g of octadecene, stir and heat to 260°C under nitrogen, add 1mL of sulfur precursor solution (dissolve 0.032g of sulfur powder in 10mL of octadecene), and reduce the reaction solution to 240 ℃, maintain 10min, inject a certain amount of zinc diethyldithiocarbamate precursor solution (dissolve 0.362g zinc diethyldithiocarbamate in 10mL oleylamine solution), raise the temperature to 180℃, maintain 20min .

[0052] CdSe@ZnS / ZnS quantum dot nanomaterials were synthesized by high temperature implantation method. A mixed solution of 0.14 mmol of cadmium acetate, 3.41 mmol of zinc oxide and 7 mL of oleic acid was heated to 150° C. in a nitrogen atmosphere, and then 15 mL of octadecene was added, followed by heating to 310° C. Rapidly inject 2 mL of selenium-sulfur precurs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence quantum yield | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com