A kind of cobalt phosphate cocatalyst modified bifeo3 thin film photoelectrode and preparation method thereof

A technology of cocatalyst and cobalt phosphate, which is applied in the field of cobalt phosphate modified BiFeO3 thin film photoelectrode and its preparation field, can solve the problems of poor photogenerated carrier mobility and high carrier recombination rate, and achieves a simple and easy preparation method. The effect of promoting application and facilitating the regulation of photoelectrochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

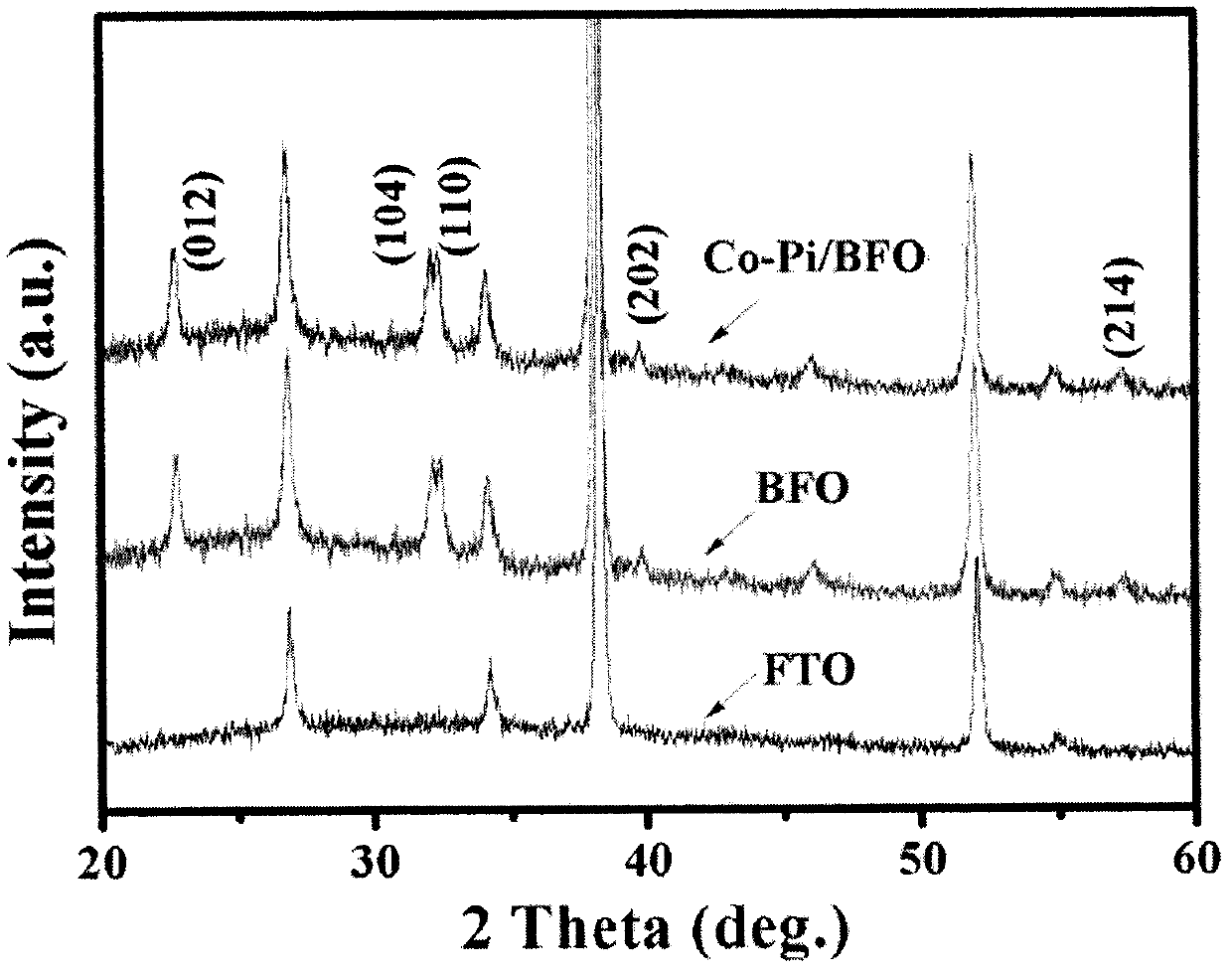

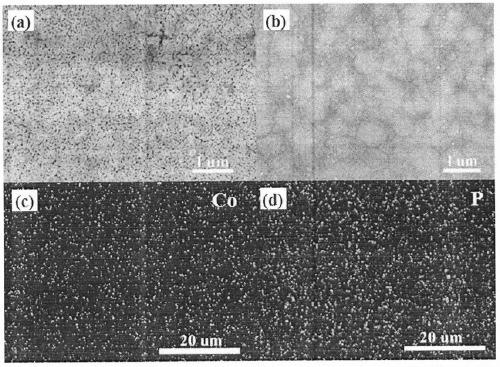

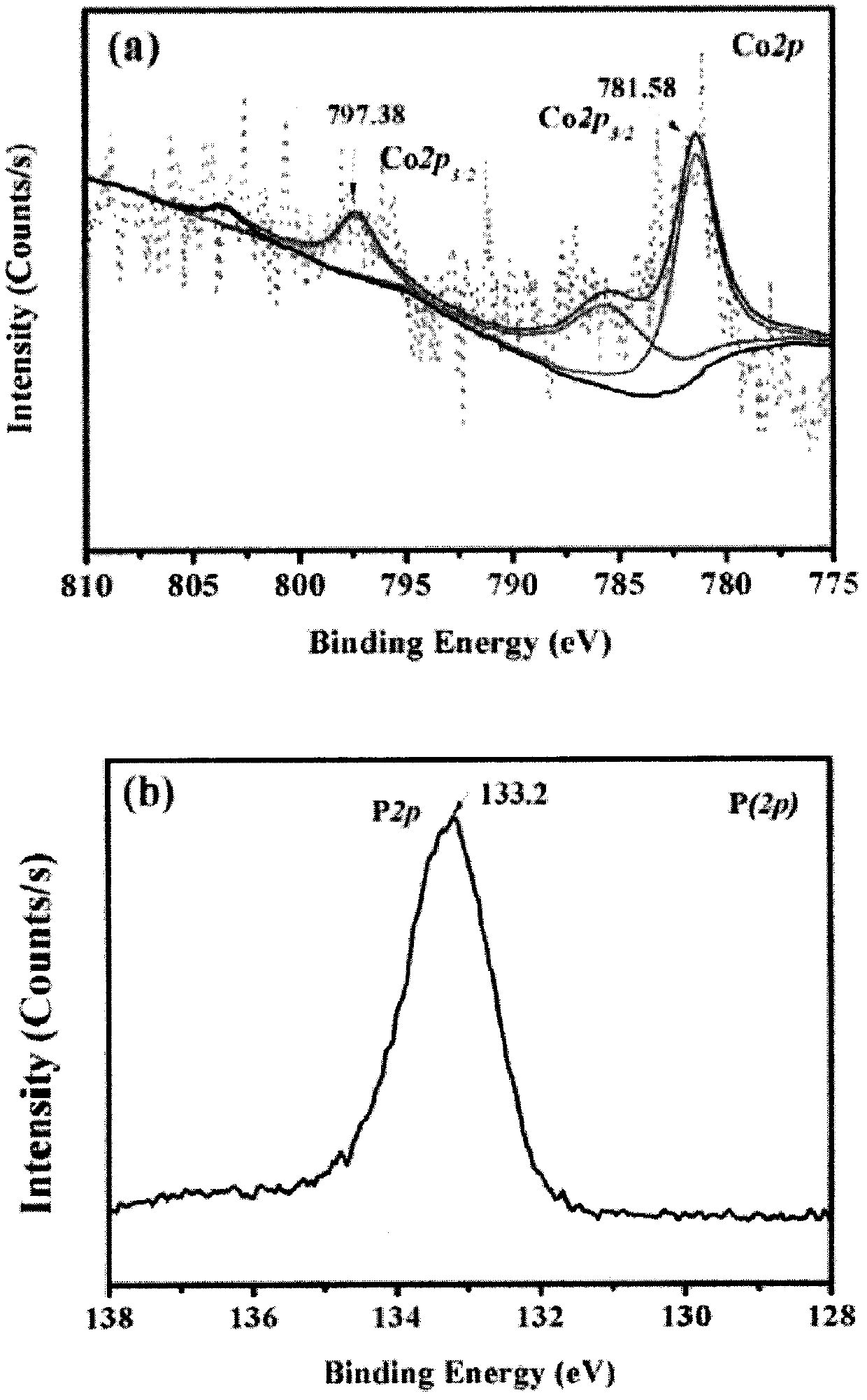

[0018] Weigh 6mmol of bismuth nitrate pentahydrate and dissolve it in 20ml of ethylene glycol, add 10ml of glacial acetic acid for dehydration after ultrasonication for 10 minutes and continue ultrasonication for 10 minutes, then add 6mmol of ferric nitrate nonahydrate, ultrasonic for 10 minutes, and finally add 1.0 g of P123 is used as a template agent, after 30 minutes of ultrasonication, it is aged at room temperature for 24 hours to obtain the precursor sol for the next step of preparing BFO thin film photoelectrodes; Spin coating on the cleaned FTO conductive glass surface, the spin coating time is 40s, and then dry on a hot table at 150 degrees, and then put the dried samples into a muffle furnace for calcination at 550 degrees, and the calcination time is 30 minutes. After naturally cooling to room temperature, the BFO film can be prepared; the BFO film prepared above was immersed in the potassium dihydrogen phosphate electrolyte solution (concentration: 0.1 M) containin...

Embodiment 2

[0021] Weigh 5mmol of bismuth nitrate pentahydrate and dissolve it in 15ml of ethylene glycol, add 10ml of glacial acetic acid for dehydration after ultrasonication for 10 minutes and continue ultrasonication for 10 minutes, then add 5mmol of ferric nitrate nonahydrate, ultrasonic for 10 minutes, and finally add 0.8 g of P123 is used as a template agent, after 30 minutes of ultrasonication, it is aged at room temperature for 24 hours to obtain the precursor sol for the next step of preparing BFO thin film photoelectrodes; Spin coating on the cleaned FTO conductive glass surface, the spin coating time is 40s, and then dry on a hot table at 150 degrees, and then put the dried samples into a muffle furnace for calcination at 550 degrees, and the calcination time is 30 minutes. After naturally cooling to room temperature, the BFO film can be prepared; the BFO film prepared above was immersed in the potassium dihydrogen phosphate electrolyte solution (concentration: 0.1 M) containin...

Embodiment 3

[0023]Weigh 10mmol of bismuth nitrate pentahydrate and dissolve it in 30ml of ethylene glycol, add 10ml of glacial acetic acid for dehydration after ultrasonication for 10 minutes and continue ultrasonication for 10 minutes, then add 10mmol of ferric nitrate nonahydrate, ultrasonic for 10 minutes, and finally add 1.5 g of P123 is used as a template agent, after 30 minutes of ultrasonication, it is aged at room temperature for 24 hours to obtain the precursor sol for the next step of preparing BFO thin film photoelectrodes; Spin coating on the cleaned FTO conductive glass surface, the spin coating time is 40s, and then dry on a hot table at 150 degrees, and then put the dried samples into a muffle furnace for calcination at 550 degrees, and the calcination time is 30 minutes. After naturally cooling to room temperature, the BFO film can be prepared; the BFO film prepared above was immersed in the potassium dihydrogen phosphate electrolyte solution (concentration: 0.1 M) containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com