Preparation method and application of magnetic modified bentonite adsorbent

A technology of bentonite and adsorbent is applied in the field of preparation of magnetically modified bentonite adsorbent, which can solve the problems of inability to achieve ferric oxide pillared magnetic bentonite, large specific surface area of bentonite, high price of zirconium, etc., and achieve excellent cation exchange performance. , Large specific surface area, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

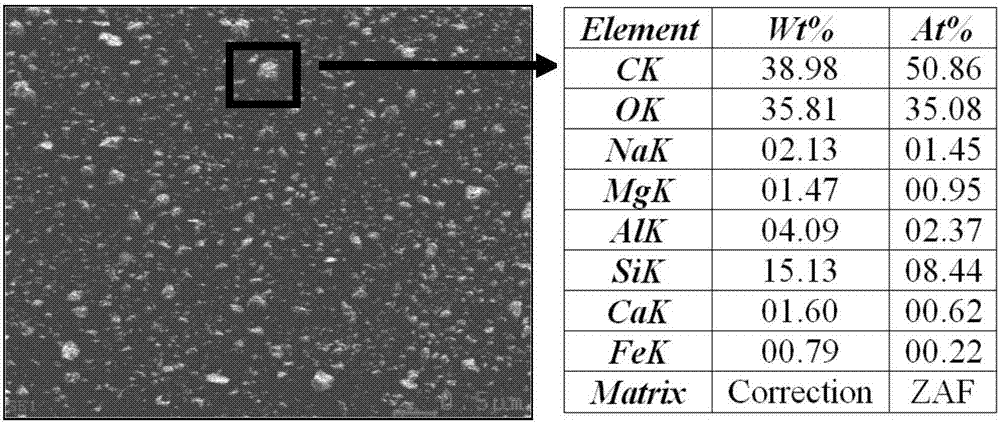

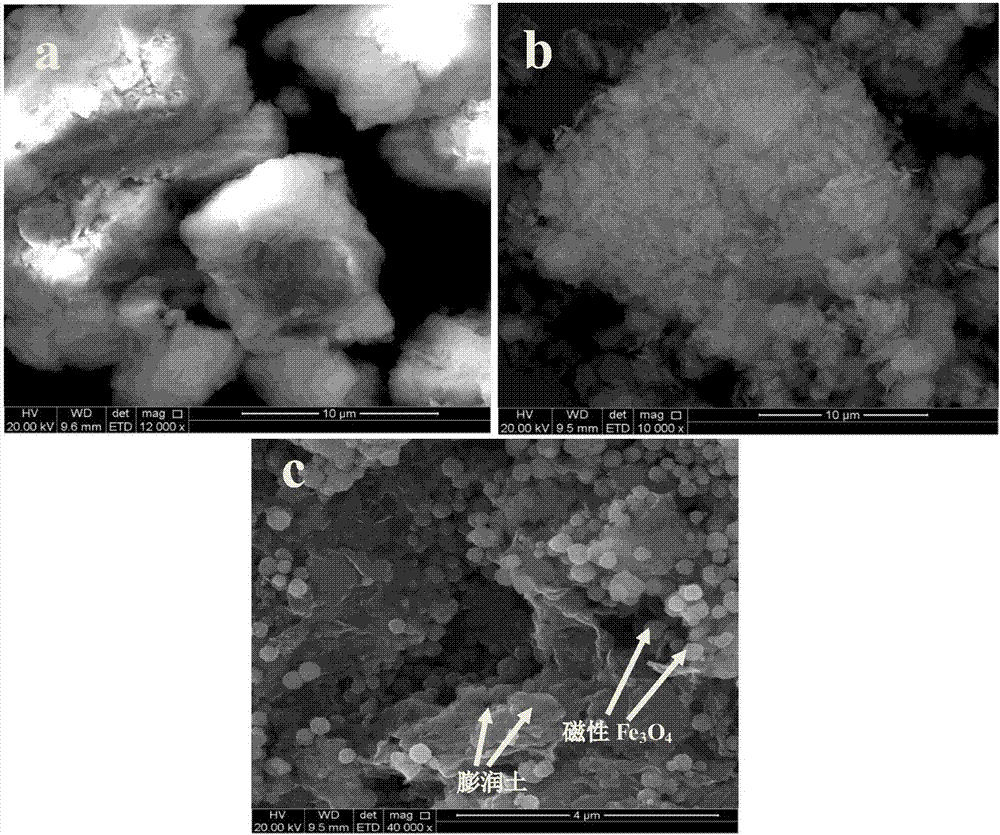

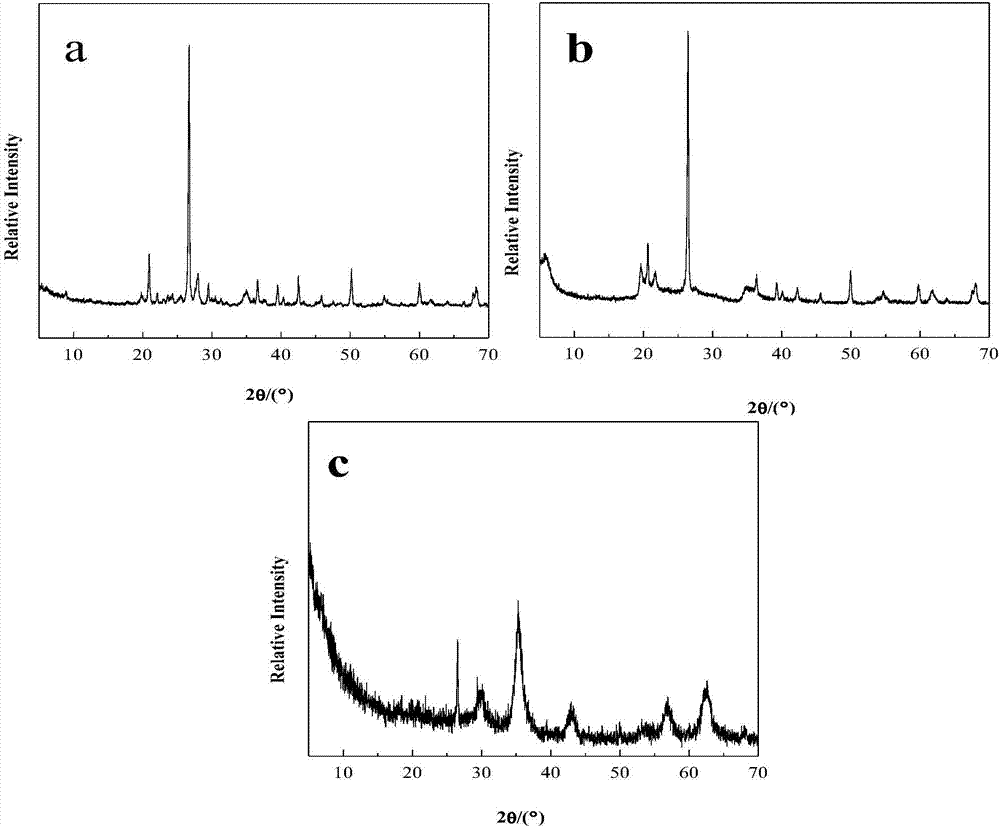

[0034] 1. Preparation of Magnetically Modified Bentonite Adsorbent

[0035] Weigh 5.4g of FeCl 3 ·6H 2 O was dissolved in 100mL of ethylene glycol, stirred for 1h, and the constant stirring speed was 400 rpm), then added 9.0g of sodium acetate, stirred for 2h, then added 1.25g of trisodium citrate, stirred evenly for 5h, and obtained yellowish brown Suspension: add heat activation (activation temperature is 350 ℃, time is 1.5h) and acid activation (activate it with hydrochloric acid whose concentration is 3wt%) to the above-mentioned yellowish brown suspension liquid, hydrochloric acid and heat activation The liquid-solid mass ratio of the bentonite after is 15:1, at 100 DEG C, the stirring speed is controlled at 400 revolutions / min, and the stirring time is 8h) after 1.333g of bentonite, the stirring speed is continued to be controlled, and the mixing and stirring is carried out for 3h to obtain a suspension Encapsulate the above suspension in a polytetrafluoroethylene reac...

Embodiment 2

[0072] 1. Preparation of magnetically modified bentonite adsorbent

[0073] Weigh 10.8g of FeCl 3 ·6H 2 O was dissolved in 200mL of ethylene glycol, stirred for 2h, and the constant stirring speed was 400 rpm), then added 18.0g of sodium acetate, stirred for 3h, then added 2.5g of trisodium citrate, stirred evenly for 6h, and obtained yellowish brown Suspension: add heat-activated (activation temperature is 380 ℃, time is 1h), acid activation (with the concentration of 2wt% hydrochloric acid to activate it, hydrochloric acid and heat-activated The liquid-solid mass ratio of bentonite is 18:1, and at a temperature of 90°C, the stirring speed is controlled at 400 rpm, and the stirring time is 9h). After 2.667g of bentonite, continue to control the stirring speed, and mix and stir for 3h to obtain a suspension; The above suspension was packaged in a polytetrafluoroethylene reactor, and reacted at 180°C for 15 hours; the black solid was washed 3 times with water and ethanol, mag...

Embodiment 3

[0078] 1. Preparation of magnetically modified bentonite adsorbent

[0079] Weigh 10g of FeCl 3 ·6H 2O was dissolved in 180mL of ethylene glycol, stirred for 3h, and the constant stirring speed was 400 rpm), then added 15.0g of sodium acetate, stirred for 2h, then added 2.0g of trisodium citrate, stirred evenly for 6h, and obtained yellowish brown Suspension: Add heat-activated (activation temperature: 350°C, time: 1.5h) and acid-activated (activated with hydrochloric acid with a concentration of 1wt%) to the above-mentioned yellow-brown suspension. After hydrochloric acid and heat-activated The liquid-solid mass ratio of the bentonite is 15:1, and the stirring speed is controlled at 400 rpm at a temperature of 80° C., and the stirring time is 10 h) after 2.3 g of the bentonite, the stirring speed is continued to be controlled, and the mixing and stirring is carried out for 2 h to obtain a suspension; The above suspension was packaged in a polytetrafluoroethylene reactor, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com