Multifunctional bio-organic fertilizer based on waste clay and application of multifunctional bio-organic fertilizer

A bio-organic fertilizer and waste white soil technology, which is applied in the treatment of bio-organic parts, the preparation of organic fertilizers and organic fertilizers, etc., can solve the problems of inability to solidify heavy metals in soil and improve soil structure, so as to reduce the occurrence of soil-borne diseases. , Shorten the decomposing cycle, and improve the effect of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

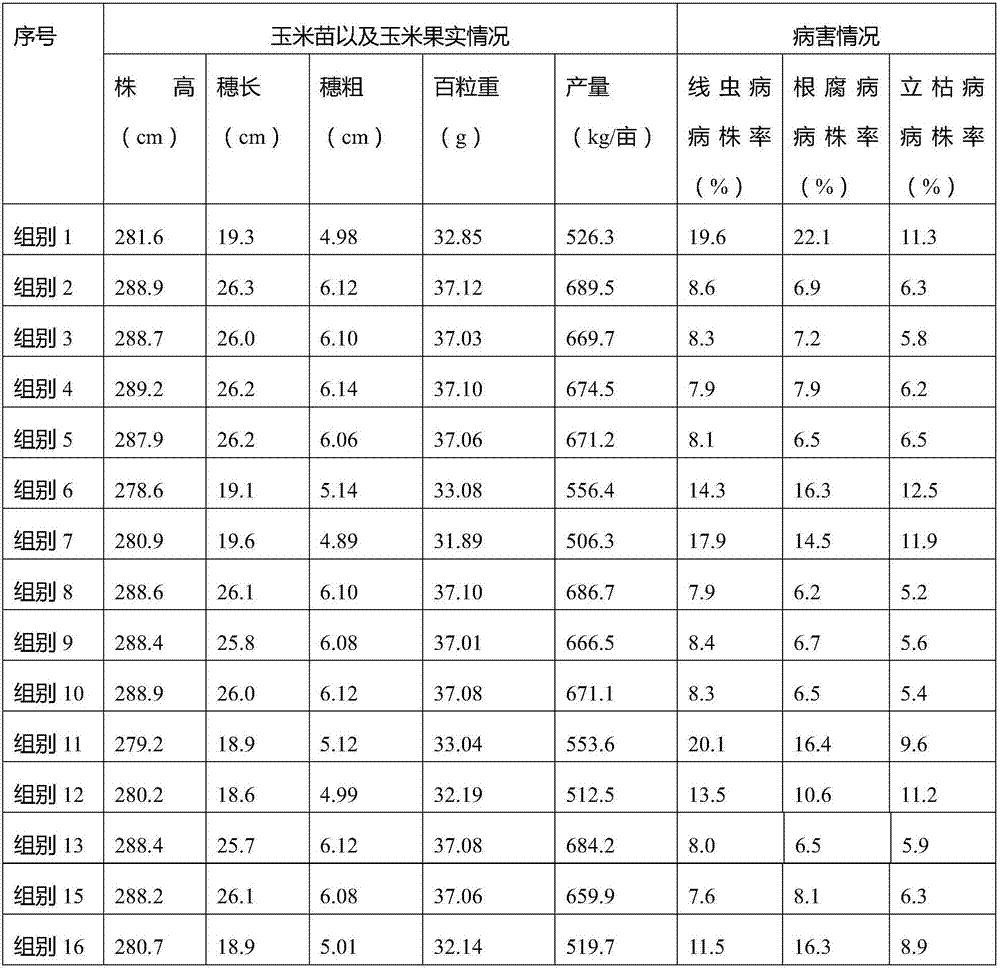

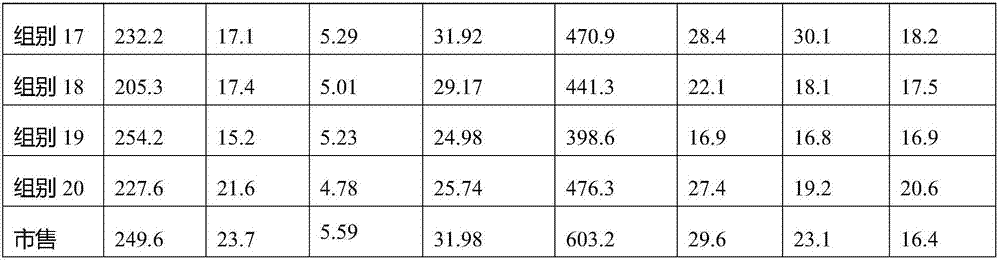

[0035] Embodiment 1 adopts the application experiment of the biological organic fertilizer of different functional additives

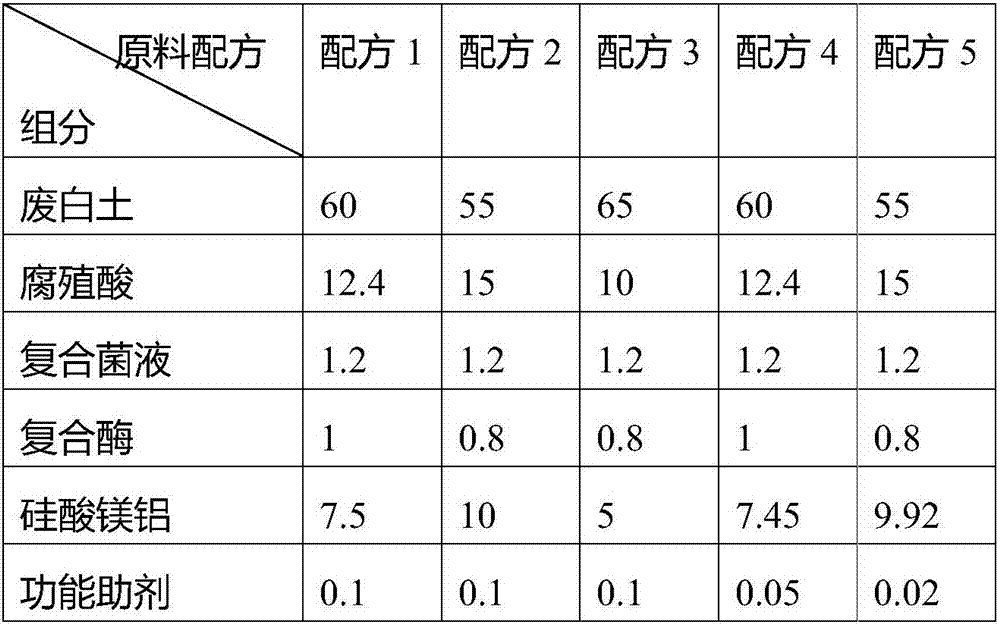

[0036] Respectively adopt the following functional additive groups and prepare bio-organic fertilizers according to Table 1 formula 1 and the above-mentioned preparation method. All raw materials are commercially purchased except waste white clay, which is self-produced waste white clay with an oil content of about 13-14% (decolorization The final waste white clay containing 20-30% oil is obtained by physical pressing at normal temperature).

[0037] Functional additive groups 1-6: composed of brassinolide and phenylpeptamine in mass ratios of 1:0.8, 1:1, 1:100, 1:200, 1:260 and 1:265;

[0038] Functional additive groups 7-11: brassinolide and malic acid mixed in a mass ratio of 1:90, 1:100, 1:120, 1:150 and 1:155;

[0039] Functional additive groups 12-16: brassinolide and polyaspartic acid mixed in a mass ratio of 1:90, 1:100, 1:150, 1:200 and 1:205...

Embodiment 2

[0051] This example provides a bio-organic fertilizer, its raw material formula is shown in Table 1, formula 2, wherein the oil content of waste clay is about 13-14%, and the functional auxiliary agent is brassinolide and phenylpeptamic acid in a mass ratio of 1:200 Mix composition. Each component is individually packaged. Before use, make organic fertilizer according to the above-mentioned method of the present invention.

Embodiment 3

[0053] This example provides a bio-organic fertilizer, its raw material formula is shown in Table 1, formula 3, wherein the oil content of waste clay is about 13-14%, and the functional additive is composed of brassinolide and malic acid in a mass ratio of 1:120 . Each component is individually packaged. Before use, make organic fertilizer according to the method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com