A step-by-step dynamic acid adjustment method for extracting molybdenum

An extraction and dynamic technology, applied in the direction of improving process efficiency, can solve the problems of flowmeter crystallization blockage, affecting extraction operation, long precipitation time, etc., and achieve the effect of eliminating the generation of three-phase substances, reducing the filtration process, and efficiently extracting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

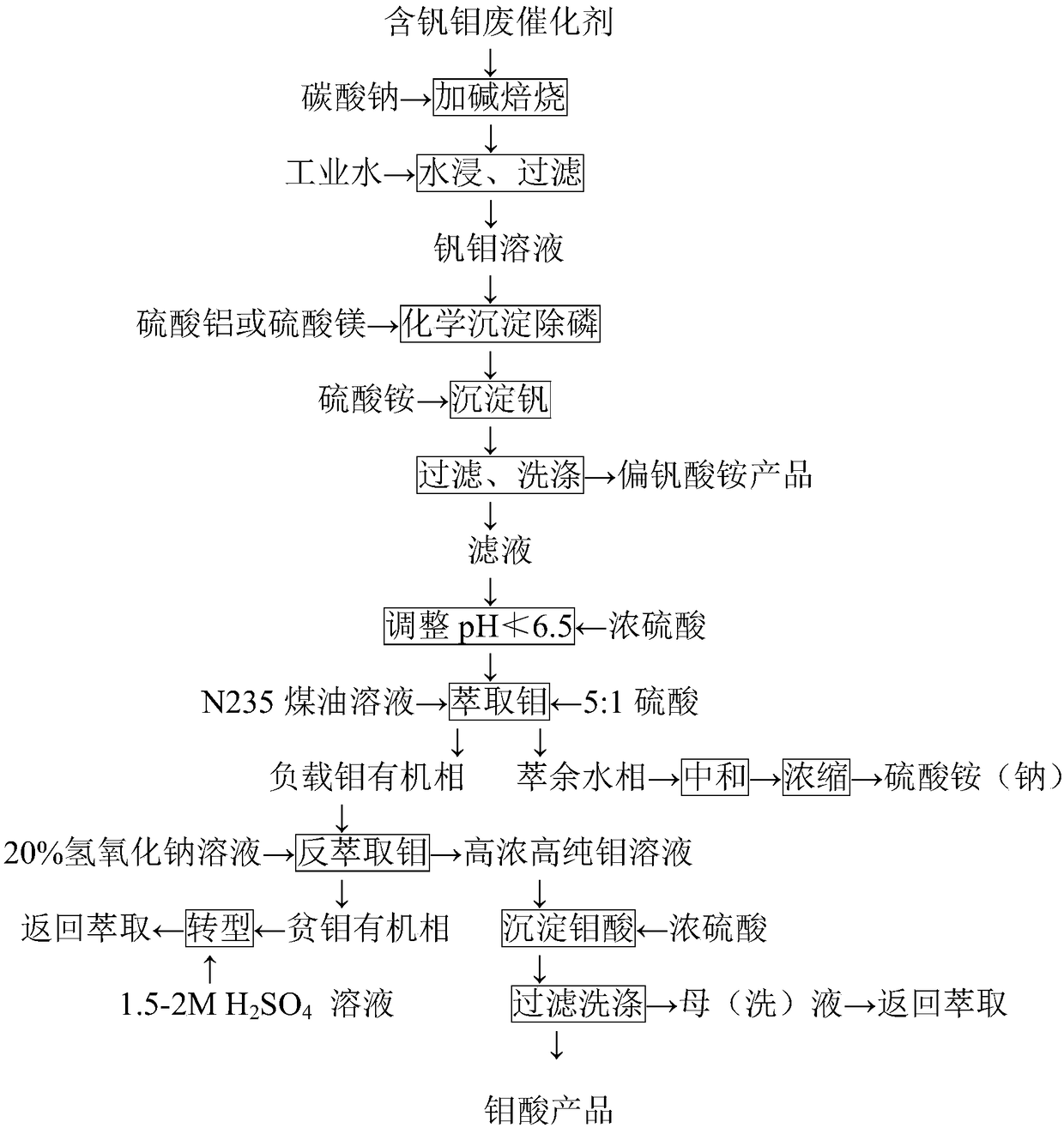

[0033] This embodiment provides a step-by-step dynamic acid adjustment method for extracting molybdenum, which includes the following steps:

[0034] S101: Mix ammonium sulfate with a waste catalyst solution containing vanadium and molybdenum, and filter after sufficient precipitation to obtain filter residue ammonium metavanadate and filtrate;

[0035] Wherein, the molar ratio of ammonium sulfate and vanadium is 3.5:1, and in the obtained filtrate, the mass concentration of vanadium is 1.51 g / L, the mass concentration of molybdenum is 12.3 g / L, and the pH value is 8.8.

[0036] S102: Use concentrated sulfuric acid with a mass fraction of 92.5% to adjust the pH of the filtrate to 6.8;

[0037] At this time, no precipitation of molybdate (ammonium) occurred, and there was no precipitation after 12 hours.

[0038] S103: Mix the extractant trioctyl tertiary amine, secondary octanol, and sulfonated kerosene uniformly in a volume ratio of 10:10:80 to obtain a tertiary amine-kerosene solution...

Embodiment 2

[0044] This embodiment provides a step-by-step dynamic acid adjustment method for extracting molybdenum, which includes the following steps:

[0045] S101: Mix ammonium sulfate with a waste catalyst solution containing vanadium and molybdenum, and filter after sufficient precipitation to obtain filter residue ammonium metavanadate and filtrate;

[0046] Wherein, the molar ratio of ammonium sulfate and vanadium is 3.2:1, and in the obtained filtrate, the mass concentration of vanadium is 1.8 g / L, the mass concentration of molybdenum is 10.5 g / L, and the pH value is 8.5.

[0047] S102: Use concentrated sulfuric acid with a mass fraction of 92.5% to adjust the pH of the filtrate to 6.5;

[0048] At this time, no precipitation of molybdate (ammonium) occurred, and there was no precipitation after 12 hours.

[0049] S103: Mix the extractant trioctyl tertiary amine, secondary octanol and sulfonated kerosene uniformly in a volume ratio of 10:10:80 to obtain a tertiary amine-kerosene solution; ...

Embodiment 3

[0055] This embodiment provides a step-by-step dynamic acid adjustment method for extracting molybdenum, which includes the following steps:

[0056] S101: Mix ammonium sulfate with a waste catalyst solution containing vanadium and molybdenum, and filter after sufficient precipitation to obtain filter residue ammonium metavanadate and filtrate;

[0057] Wherein, the molar ratio of ammonium sulfate and vanadium is 3.0:1, and in the obtained filtrate: the mass concentration of vanadium is 2.25 g / L, the mass concentration of molybdenum is 8.6 g / L, and the pH value is 9.0.

[0058] S102: Use concentrated sulfuric acid with a mass fraction of 92.5% to adjust the pH of the filtrate to 6.7;

[0059] At this time, no precipitation of molybdate (ammonium) occurred, and there was no precipitation after 12 hours.

[0060] S103: The extractant trioctyl tertiary amine, secondary octanol and sulfonated kerosene are mixed uniformly in a volume ratio of 10:10:80 to obtain a tertiary amine-kerosene solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com