Separation integration system and separation integration method for ethyl acetate-water system

A technology of ethyl acetate and integration method, which is applied in the field of separation and integration system of ethyl acetate-water system, can solve the problems of high energy consumption and complex process, and achieve low energy consumption, simple process, production cost and equipment investment reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

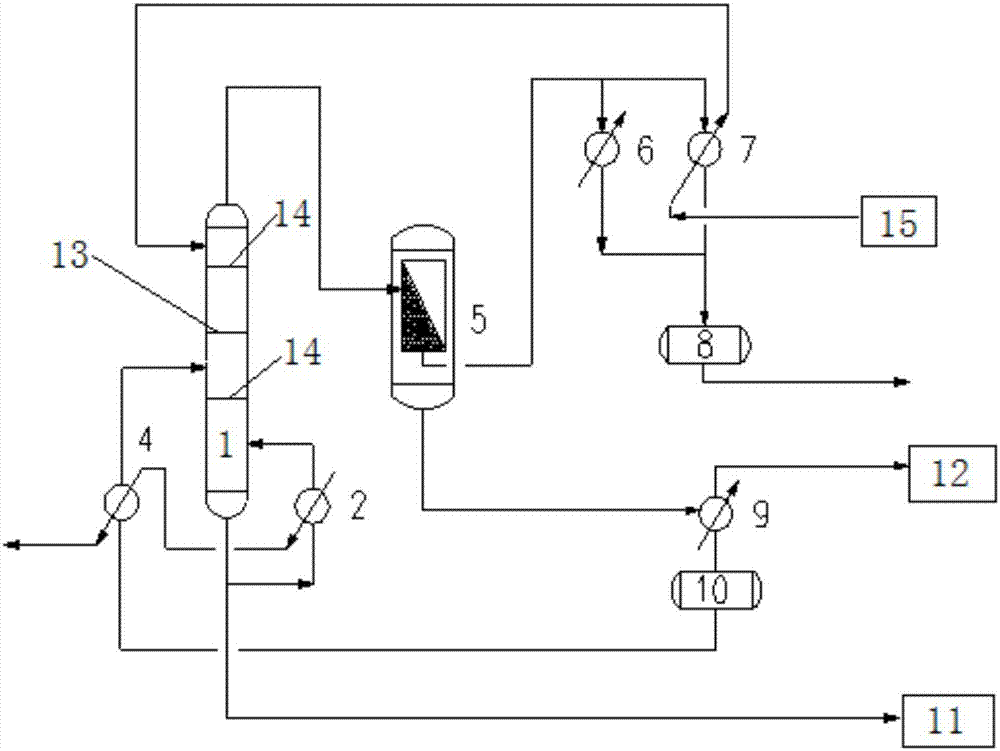

[0039] Such as figure 1 Shown, a kind of separation integration system of ethyl acetate and water comprises the ethyl acetate rectification dehydration unit and the ethyl acetate membrane dehydration unit connected with each other by pipelines, and valves are all arranged on each pipeline;

[0040] The ethyl acetate rectification dehydration unit comprises an ethyl acetate dehydration tower 1, a reboiler 2 and a permeate preheater 4; the top and the bottom of the ethyl acetate dehydration tower 1 are respectively provided with a raw material feed port and a permeate liquid feed port; the permeate feed port communicates with the hot side discharge port of the permeate preheater 4, the air inlet at the lower end of the ethyl acetate dehydration tower 1 communicates with the gas phase outlet of the reboiler 2, and the reboiler 2 The liquid phase outlet of the liquid phase is communicated with the feed port on the hot side of the permeate preheater 4; the water outlet at the botto...

Embodiment 2

[0052] The integrated system for separation of ethyl acetate and water described in this example is basically the same as in Example 1, except that the membrane module is a hydrophilic inorganic membrane, specifically a porous alumina-loaded NaA molecular sieve membrane Ethyl acetate dehydration tower 1 has a high-efficiency packed tower and a plate tower composite tower structure, a layer of gas phase distribution tray 13 is set at a distance of 500mm above the permeate feed inlet, and a distance of 500mm below the feed inlet of the water-containing ethyl acetate raw material and the permeate inlet Two layers of feed and liquid receiving trays 14 are arranged at a distance of 500 mm below the feed opening.

[0053] Utilize above-mentioned ethyl acetate and water separation integrated system to separate and integrate the ethyl acetate raw material that water content is 1wt%, to produce the operation method and control condition of the ethyl acetate product that water content is...

Embodiment 3

[0060] The separation and integration system of a kind of ethyl acetate and water described in this embodiment is basically the same as that of Embodiment 2, the difference is that: the membrane module is a hydrophilic organic membrane, specifically polyvinyl alcohol (PVA) / Polyacrylonitrile (PAN) composite membrane.

[0061] Utilize above-mentioned ethyl acetate and the separation integration system of water to separate and integrate the ethyl acetate raw material that water content is 8.1wt%, to produce the operation method and control condition of the ethyl acetate product that water content is 0.1wt% as follows:

[0062] The aqueous ethyl acetate raw material is sent to the raw material inlet at the top of the ethyl acetate dehydration tower 1 after being preheated by the raw material preheater 7, and the preheating temperature of the aqueous ethyl acetate raw material is controlled by adjusting the cooling medium flow rate of the ethyl acetate product condenser 6 At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com