Carbonyl iron/graphene/polyvinylpyrrolidone compound wave-absorbing material, preparation method thereof and prepared wave-absorbing plate prepared by method

A technology of polyvinylpyrrolidone and composite wave-absorbing materials, which is applied in the field of wave-absorbing sheets, can solve problems such as narrow effective frequency bands, achieve the effects of expanding effective wave-absorbing bandwidth, action frequency bandwidth, and solving electromagnetic leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

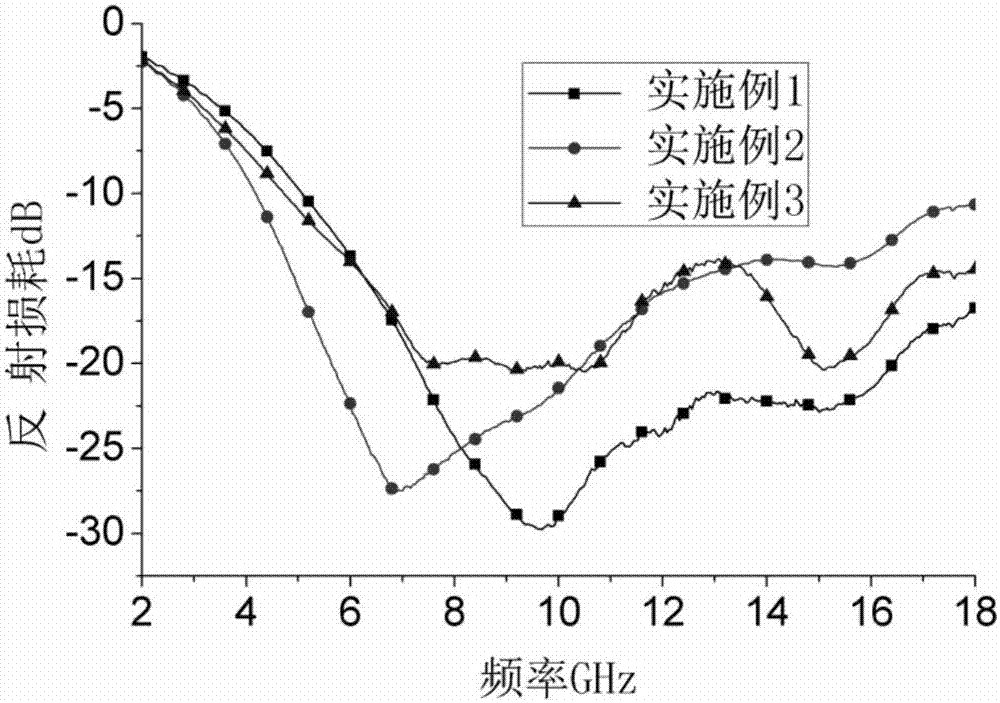

Embodiment 1

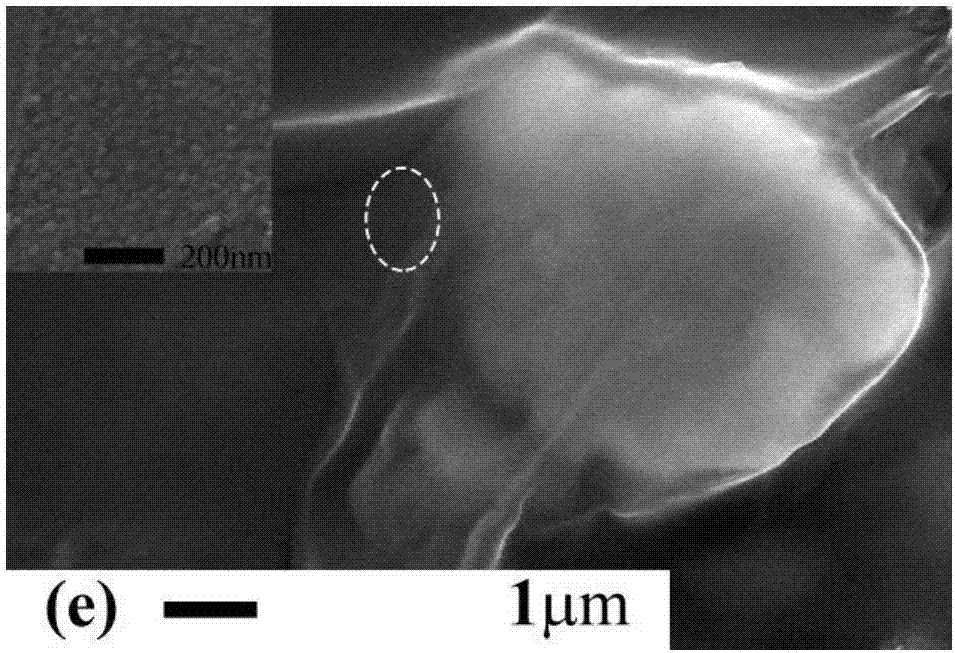

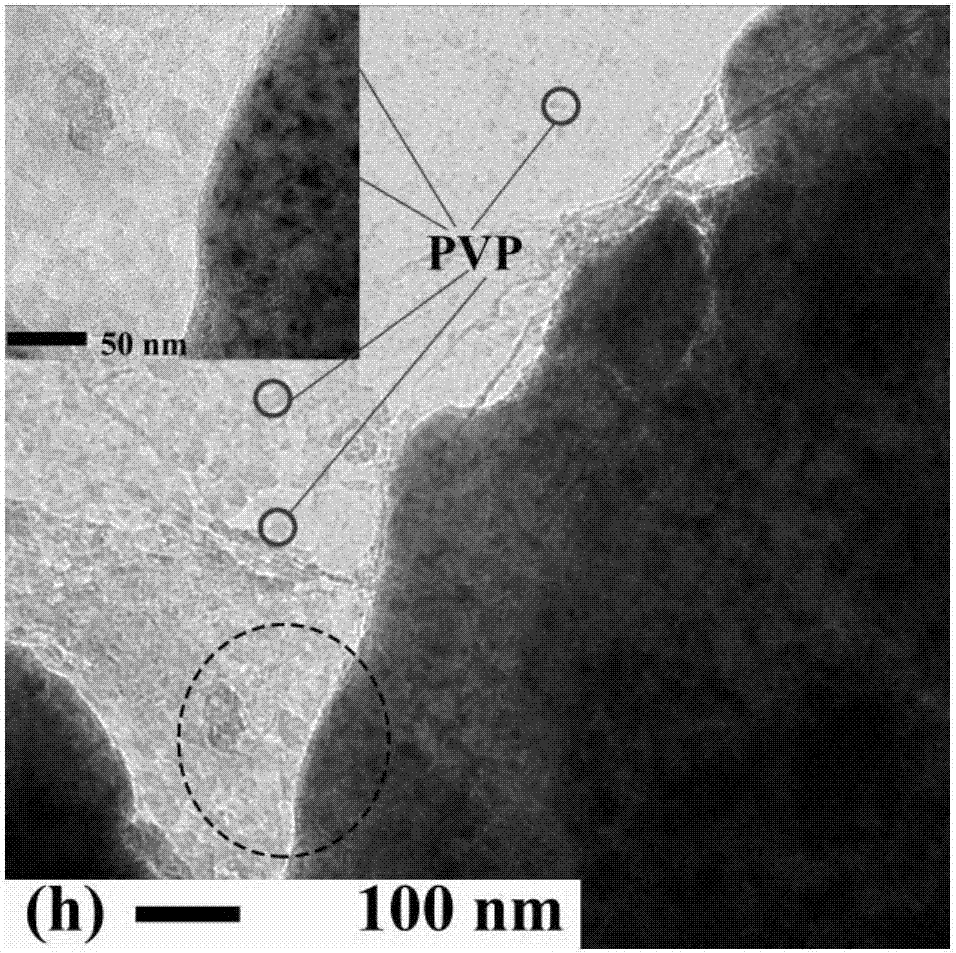

[0037] A preparation of composite absorbing material

[0038] Mix carbonyl iron powder, zirconia beads, and absolute ethanol into the planetary ball mill with a mass ratio of 1:80:10, maintain the speed of the ball mill at 1000 rpm, and mill for 4 hours; Drying in a vacuum drying oven at 60° C. to constant weight to obtain carbonyl iron powder with a particle size of 0.5-1.5 μm after ball milling.

[0039]Use 200 mesh natural graphite powder, 98% concentrated sulfuric acid, sodium nitrate, potassium permanganate, and 3% hydrogen peroxide. Graphite powder, concentrated sulfuric acid, and sodium nitrate were mixed at a mass ratio of 1:0.6:45 with a magnetic stirring speed of 250rpm for 8 minutes, cooled in an ice-water bath to below 5°C, and then potassium permanganate powder 5 times the mass of graphite powder was slowly added to the above mixture, and stirred React for 35 minutes, and control the temperature of the reaction process below 20°C; then raise the temperature to 30...

Embodiment 2

[0049] A preparation of composite absorbing material

[0050] Mix carbonyl iron powder, zirconia beads, and absolute ethanol into the planetary ball mill with a mass ratio of 1:90:12, maintain the speed of the ball mill at 1100rpm, and mill for 3 hours; Drying in a vacuum drying oven at 60° C. to constant weight to obtain carbonyl iron powder with a particle size of 0.5-1.5 μm after ball milling.

[0051] Use 300 mesh natural graphite powder, 98% concentrated sulfuric acid, sodium nitrate, potassium permanganate, and 3% hydrogen peroxide. Graphite powder, concentrated sulfuric acid, and sodium nitrate were mixed at a mass ratio of 1:0.5:42.3 with a magnetic stirring speed of 200rpm for 10 minutes, cooled in an ice-water bath to below 5°C, and then potassium permanganate powder 4 times the mass of graphite powder was slowly added to the above mixture, and stirred React for 30 minutes, and control the temperature of the reaction process below 20°C; then raise the temperature to...

Embodiment 3

[0057] A preparation of composite absorbing material

[0058] Mix carbonyl iron powder, zirconia beads, and absolute ethanol into the planetary ball mill with a mass ratio of 1:70:8, maintain the speed of the ball mill at 900 rpm, and mill for 5 hours; Drying in a vacuum drying oven at 60° C. to constant weight to obtain carbonyl iron powder with a particle size of 0.8-2.3 μm after ball milling.

[0059] Use 400 mesh natural graphite powder, 98% concentrated sulfuric acid, sodium nitrate, potassium permanganate, and 3% hydrogen peroxide. Graphite powder, concentrated sulfuric acid, and sodium nitrate were mixed at a mass ratio of 1:0.4:38 with a magnetic stirring speed of 150rpm for 12 minutes, cooled in an ice-water bath to below 5°C, and then potassium permanganate powder three times the mass of graphite powder was slowly added to the above mixture, and stirred React for 25 minutes, and control the reaction temperature below 20°C; then raise the temperature to 40°C, continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com