Functional compound accelerant for methane fermentation and preparation method thereof

A composite accelerator, biogas fermentation technology, applied in fermentation, biological sludge treatment, waste fuel, etc., can solve the problems of short duration of gas production peak, low utilization rate of fermentation substrate, and inability to operate normally, and achieve improvement. Efficiency, shortened fermentation start-up time, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

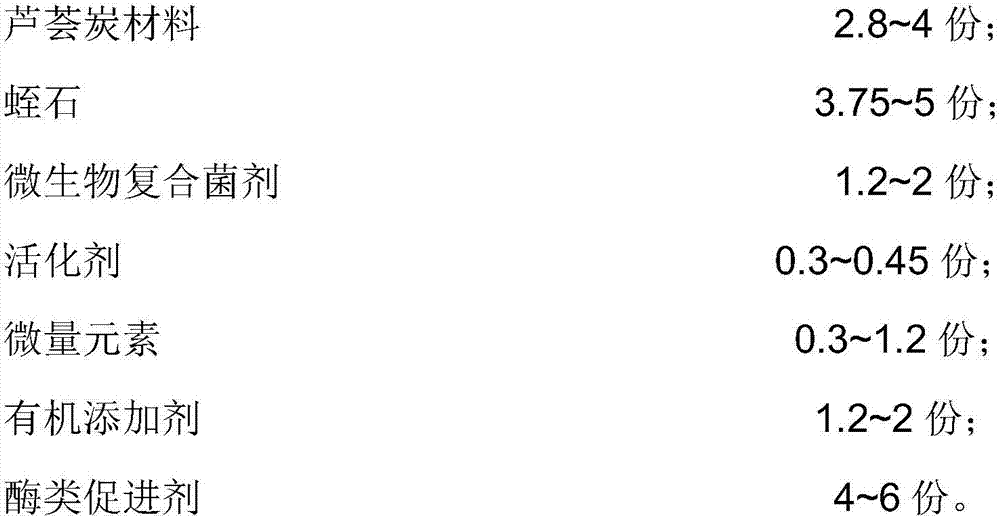

Method used

Image

Examples

Embodiment 1

[0057] 1) Preparation of vermiculite microcrystallized powder:

[0058] Grinding and grinding 3.75 parts of vermiculite, adding 0.35 parts of ethylene glycol, and preparing it through ultra-fine processing so that the average particle size reaches 400 mesh or more to obtain microcrystalline powder, which is packed for later use;

[0059] 2) Preparation of functional accelerator:

[0060] The mass parts are 3 parts of aloe carbon material, 1.5 parts of hydrolytic bacteria, 1 part of trace element Fe, 1.6 parts of organic additives (0.4 part of urea, 0.6 part of phosphate fertilizer, 0.6 part of citric acid) and 5 parts of enzyme accelerator (protease 1.5 parts, 1 part of cellulase, 0.5 part of lipase, 1 part of amylase, 1 part of nuclease) and step 1) microcrystalline powder are mixed uniformly at room temperature to obtain a functional compound accelerator for biogas fermentation.

[0061] 3) Using functional accelerators for biogas fermentation:

[0062] With 60 parts of co...

Embodiment 2

[0064] 1) Preparation of vermiculite microcrystallized powder:

[0065] Grinding and grinding 4.2 parts of vermiculite, adding 0.3 parts of ethylene glycol, and preparing through ultra-fine processing to obtain a microcrystalline powder with an average particle size of 400 mesh or more, which is packed for later use;

[0066] 2) Preparation of functional accelerator:

[0067] The mass parts are 2.8 parts of aloe carbon material, 1.2 parts of hydrogen-producing bacteria, 1.2 parts of trace element Co, 1.6 parts of organic additives (0.8 part of urea, 0.3 part of phosphate fertilizer, 0.5 part of citric acid) and 5 parts of enzyme accelerator ( 0.5 part of protease, 2 parts of cellulase, 1 part of lipase, 1 part of amylase, 0.5 part of nuclease) and step 1) microcrystalline powder are mixed uniformly at room temperature to obtain a functional compound accelerator for biogas fermentation.

[0068] 3) Using functional accelerators for biogas fermentation:

[0069] With 60 parts ...

Embodiment 3

[0071] 1) Preparation of vermiculite microcrystallized powder:

[0072] Crush and grind 5 parts of vermiculite, add 0.4 parts of propylene diamine phosphate, and prepare through ultra-fine processing so that the average particle size reaches 400 mesh or more to obtain microcrystalline powder, which is packed for later use;

[0073] 2) Preparation of functional accelerator:

[0074] The mass parts are 3 parts of aloe charcoal material, 2 parts of acetogenic bacteria, 0.3 part of trace element Ni, 1.6 parts of organic additives (0.4 part of urea, 0.6 part of phosphate fertilizer, 0.6 part of citric acid) and 6 parts of enzyme accelerator ( 1.5 parts of protease, 2 parts of cellulase, 0.5 part of lipase, 1 part of amylase, 1 part of nuclease) and step 1) microcrystalline powder are mixed uniformly at room temperature to obtain a functional compound accelerator for biogas fermentation.

[0075] 3) Using functional accelerators for biogas fermentation:

[0076] With 80 parts of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com