Extraction method for active parts of rose flower residue and application of extraction method

A technology of active parts and rose slag, applied in the field of chemical technology, can solve problems such as increased production costs, high personnel requirements, cumbersome processes, etc., and achieve the effects of short production cycle, simple production process and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] 1. Preparation of rose pomace extract

[0053] Get 9kg of rose pomace, add 11 times the quality of enzymolysis solution (enzymolysis solution is 2W / V% cellulase, 1W / V% hemicellulase, 0.5W / V% pectinase, 0.5W / V% Isolated enzyme, pH 6.5; the above enzyme was purchased from Henan Zhengxing Food Additive Co., Ltd.), soaked for 40 minutes, and extracted 3 times by crushing tissue, 3 minutes each time, filtered with eight layers of gauze, added a certain amount of filter residue and extracted 3 times again, each 3 minutes, so repeated three times. The filtrates were combined three times and concentrated into an extract with a multi-stage flash evaporator.

[0054] 2. Organic solvent gradient extraction

[0055] Take 55 grams of rose slag extract, add 350 mL of water to disperse, and make the specific gravity about 1.2. Ultrasound for 20 minutes to help dissolve, followed by extraction with ethyl acetate, ethyl acetate:95% ethanol=6:2, after the extraction, spin off the resi...

Embodiment 2

[0081] 1. The extraction method of the active part of rose dregs, the steps are as follows:

[0082] (1) Preparation of rose dregs extract: take rose dregs, add 11 times the mass of enzymatic hydrolysis solution, soak for 55 minutes, extract 3 times by tissue breaking method, 3 minutes each time, filter with eight layers of gauze, combine the filtrate, and The multi-stage flash evaporator recovers the solvent and concentrates it into a paste. The enzymolysis liquid is 2W / V% cellulase, 1W / V% hemicellulase, 0.5W / V% pectinase, 0.5W / V% isolated enzyme, and the pH is 6.5.

[0083] (2) Gradient extraction of rose dregs extract, separating organic phase and water phase, and obtaining active site DRFR-A and active site DRFR-B from the organic phase: take the rose dregs extract obtained in step (1), add water to make Suspend to make the specific gravity at 1.2, and extract with ethyl acetate solution and ethyl acetate-ethanol mixed solution respectively. After the extraction is comple...

Embodiment 3

[0092] 1. The extraction method of the active part of rose dregs, the steps are as follows:

[0093] (1) Preparation of rose slag extract: take rose slag, add 9 times the mass of enzymatic hydrolysis solution, soak for 50 minutes, extract 3 times by tissue fragmentation, 3 minutes each time, filter with eight layers of gauze, combine the filtrate, and The multi-stage flash evaporator recovers the solvent and concentrates it into a paste. The enzymolysis liquid is 2W / V% cellulase, 1W / V% hemicellulase, 0.5W / V% pectinase, 0.5W / V% isolated enzyme, and the pH is 6.5.

[0094] (2) Gradient extraction of rose dregs extract, separating organic phase and water phase, and obtaining active site DRFR-A and active site DRFR-B from the organic phase: take the rose dregs extract obtained in step (1), add water to make Suspend to make the specific gravity at 1.2, and extract with ethyl acetate solution and ethyl acetate-ethanol mixed solution respectively. After the extraction is completed, ...

PUM

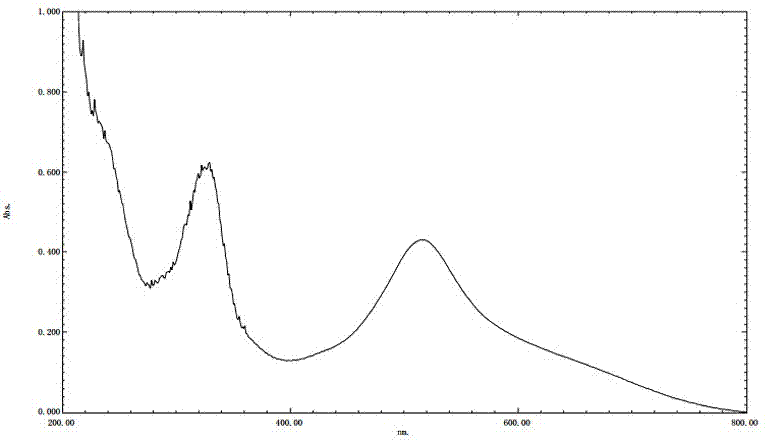

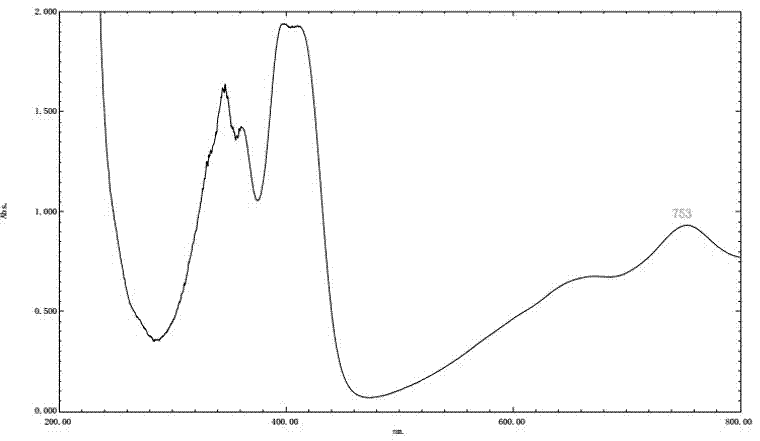

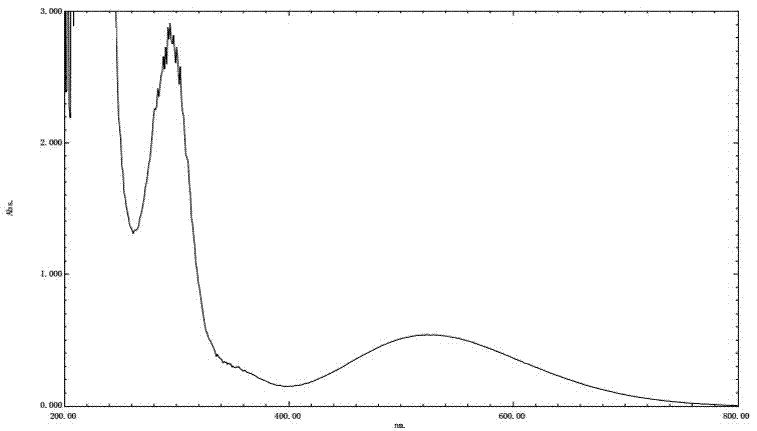

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com