Catalyst, preparation method thereof and method for removing nitrogen oxide

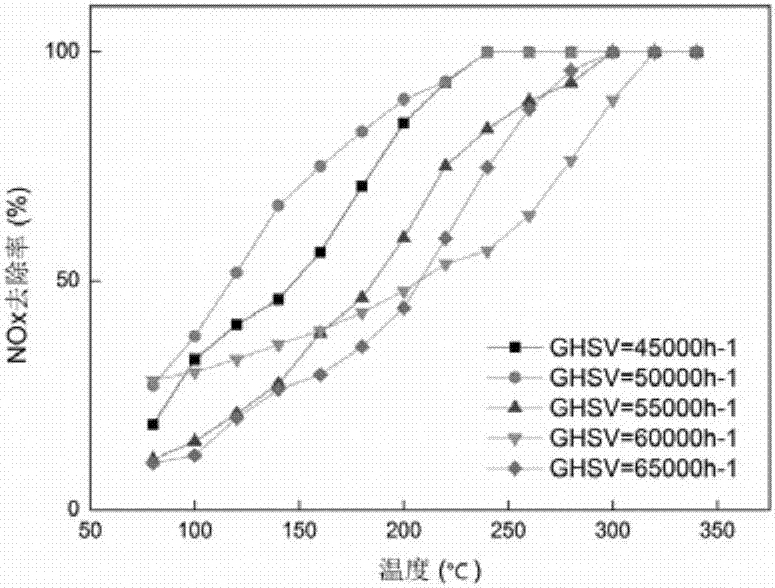

A catalyst and oxide stone technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of low catalytic activity and difficult application, and achieve the effect of improving specific surface area, increasing contact area, and promoting SCR reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the catalyst provided in the embodiment of the present invention comprises:

[0030] In step S101, a composite material containing composite titanium dioxide and graphene oxide is prepared by a sol-gel method.

[0031] In the embodiment of the present invention, the method for preparing the composite material by the sol-gel method is as follows:

[0032] Add tetrabutyl titanate and absolute ethanol into a dry beaker, and keep stirring and mixing at room temperature (eg, 20-30° C.). The volume ratio of tetrabutyl titanate to absolute ethanol may be 20-30:40, or 22:40, or 23:40, or 25:40, or 26:40, or 28:40. Preferably, the volume ratio of tetrabutyl titanate to absolute ethanol is 25.5:40.

[0033] Further, in the stirring and mixing process, the stirring process is carried out before the action of ultrasonic waves. For example, after stirring for 30 minutes, ultrasonic treatment is performed. The treatment time of ultrasonic waves is prefer...

Embodiment 1

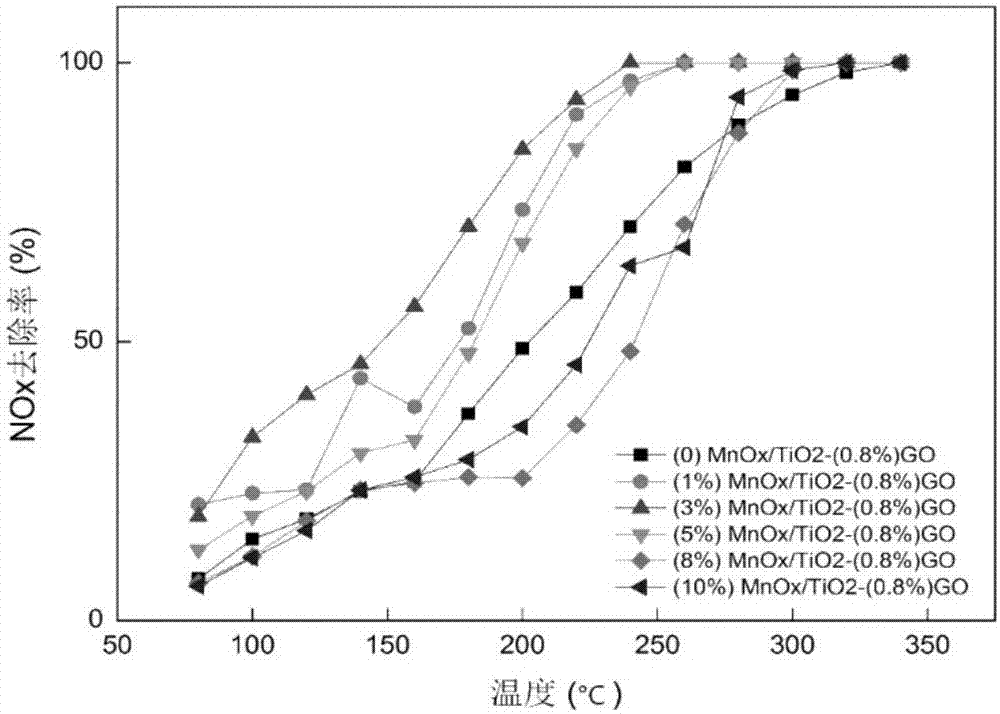

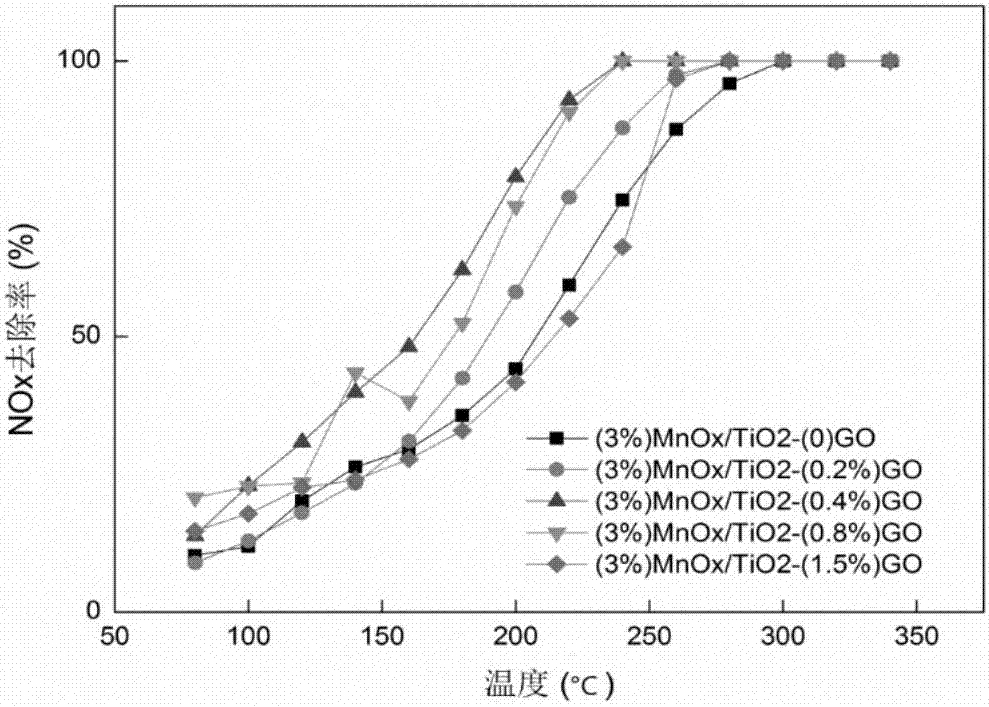

[0053] A catalyst containing 0.2 wt % of graphene oxide and 1 wt % of transition metal (MnOx).

[0054] The preparation method of the catalyst is as follows: 25 mL of tetrabutyl titanate and 40 mL of absolute ethanol are stirred and mixed, and then 1 mL of hydrochloric acid and 4 mL of glacial acetic acid are added to continue stirring for 30 minutes to obtain A solution. By oxidizing graphite into graphite oxide, and then ultrasonically treating the graphite oxide aqueous solution to obtain a graphene oxide concentration aqueous solution, taking 25 mL of it and mixing it with 15 mL of anhydrous ethanol, and stirring for 30 minutes to obtain B solution. The B solution was added dropwise to 60 mL of the A solution, and the gel sample was obtained by ultrasonication and stirring. The gel samples were aged in air for 48 hours, dried at 120°C and ground, then calcined at 450°C in nitrogen atmosphere for 6 hours, cooled to room temperature and ground to obtain a composite material....

Embodiment 2

[0056] A catalyst containing 1.5 wt % of graphene oxide and 10 wt % of transition metal (MnOx).

[0057] The preparation method of the catalyst is as follows: 25 mL of tetrabutyl titanate and 40 mL of absolute ethanol are stirred and mixed, and then 4 mL of glacial acetic acid and 1 mL of hydrochloric acid are added to continue stirring for 30 minutes to obtain A solution. An aqueous solution with a graphene oxide concentration of 2 mg / mL was prepared, 22 mL was mixed with 15 mL of anhydrous ethanol, and stirred for 30 minutes to obtain solution B. The B solution was added dropwise to 60 mL of the A solution, and the gel sample was obtained by ultrasonication and stirring. The gel samples were aged in air for 48 hours, dried at 120°C and ground, then calcined at 450°C in nitrogen atmosphere for 6 hours, cooled to room temperature and ground to obtain a composite material. The dipping solution was obtained by mixing manganese acetate and water, and the dipping solution was hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com