Carbon quantum dot-nickel titanate compounded degradation agent for degrading antibiotics and preparation method of carbon quantum dot-nickel titanate compounded degradation agent

A technology of carbon quantum dots and nickel titanate, which is applied in the field of photocatalytic degradation of organic pollutants, can solve the problems of reducing photocatalytic activity and achieve the effects of improving photocatalytic activity, easy control of reaction conditions, and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a carbon quantum dot-nickel titanate composite degradation agent for degrading antibiotics of the present embodiment, comprising the following steps:

[0026] (1) 2.48g of nickel acetate, 3.4g of tetrabutyl titanate and 1.47g of sodium citrate were added to 100mL of ethylene glycol, mixed and stirred evenly to obtain a nickel titanate precursor solution;

[0027] (2) Dissolve glucose in deionized water to form a glucose solution with a concentration of 0.6M; take 10mL of the glucose solution, add 0.35mL of ethylenediamine, stir well, and react at 180°C for 6h to obtain a carbon quantum dot solution;

[0028] (3) Mix the 50mL nickel titanate precursor solution obtained in step (1) with the 5mL carbon quantum dot solution obtained in step (2), stir well and then carry out hydrothermal reaction at 150°C for 20h, after the reaction is completed Centrifuge, wash the precipitated product with deionized water and ethanol in sequence, and dry at 50° C. f...

Embodiment 2

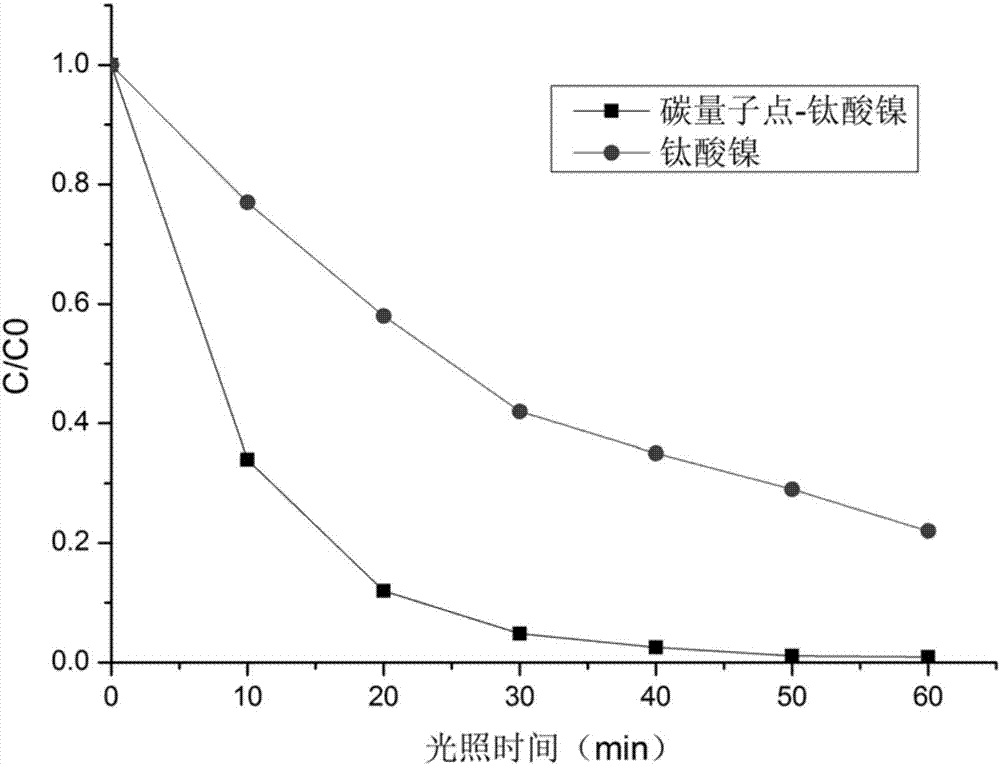

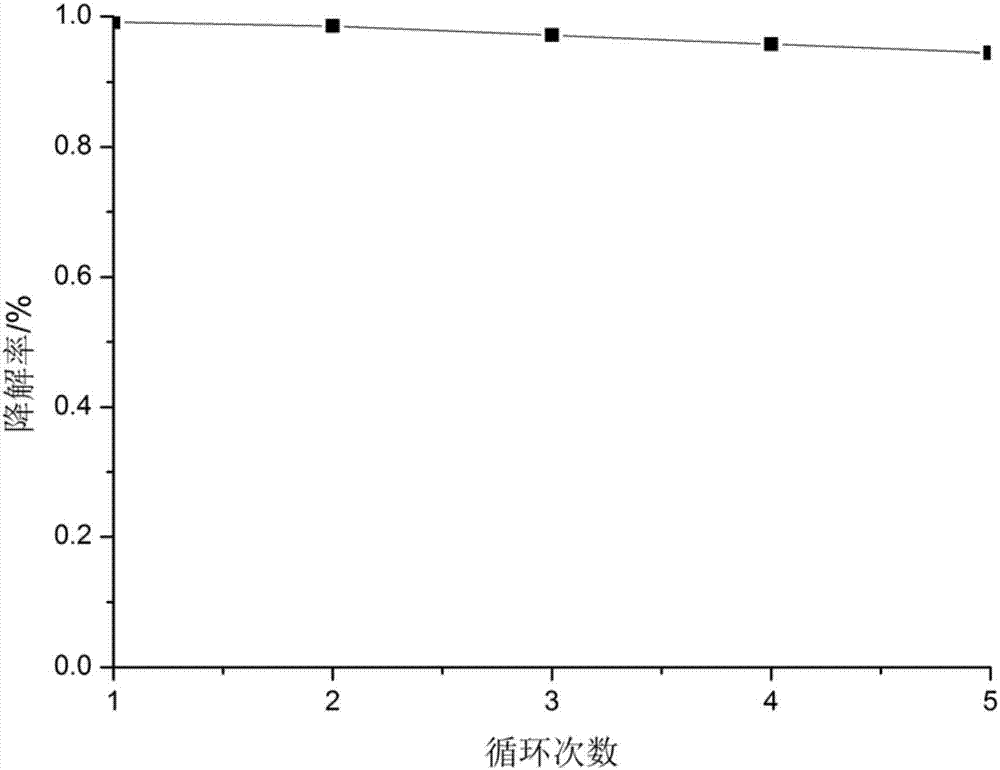

[0038] Stability study of the carbon quantum dot-nickel titanate composite degradation agent of embodiment 1 in the process of photocatalytic degradation of acetylspiramycin:

[0039]a. Weigh the carbon quantum dot-nickel titanate composite degradation agent of 10mg embodiment 1, add to the waste water of the acetylspiramycin that 100ml concentration is 10mg / L; On a magnetic stirrer, stir for 1 h in the dark to achieve adsorption equilibrium, measure its concentration with a UV-visible spectrophotometer, and record it as C 0 .

[0040] b. The acetylspiramycin solution added with the photocatalyst in step a is subjected to a photocatalytic reaction under a 500W xenon lamp of a visible light source and starts timing, and the distance between the light source and the liquid surface is 20cm. After 60 minutes of light reaction, turn off the xenon lamp. The solution after the reaction was centrifuged, and the residual concentration C of pollutants in the supernatant was measured w...

Embodiment 3

[0043] (1) adding nickel acetate, tetrabutyl titanate and sodium citrate to ethylene glycol with a molar ratio of 1:1:0.5, mixing and stirring evenly to obtain a nickel titanate precursor solution;

[0044] (2) Glucose is dissolved in deionized water to be configured as a glucose solution with a concentration of 0.6M; ethylenediamine is added to the glucose solution, wherein the volume ratio of ethylenediamine and glucose solution is 0.5:10, and the mixture is stirred at 200 Reaction at ℃ for 8 hours to obtain a carbon quantum dot solution;

[0045] (3) the nickel titanate precursor solution of step (1) gained and the carbon quantum dot solution of step (2) gained are mixed, wherein, the volume ratio of nickel titanate precursor solution and carbon quantum dot solution is 30:5, After stirring evenly, carry out hydrothermal reaction at 150°C for 4 hours. After the reaction is completed, centrifuge, wash the precipitated product with deionized water and ethanol in turn, and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com