Visible light-near infrared band solid state photocatalytic purifying film apparatus

A technology of catalytic purification and thin-film devices, applied in the field of photocatalysis, can solve problems such as air secondary pollution, impact on health, practicality and use range limitations, and achieve the effect of enhancing metal absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

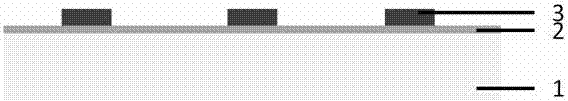

[0031] Such as figure 1 As shown, the substrate 1 is glass, the semiconductor 2 is titanium dioxide, the metal 3 is gold, the semiconductor 2 is evenly covered on the substrate 1, and the metal 3 sheet-like micro-nano structure is on the semiconductor 2 to form a metal-semiconductor composite micro-nano structure . The structure can be prepared by the following steps: uniformly deposit a layer of titanium dioxide film on the glass substrate, spin-coat a layer of photoresist on it, and use multi-beam interference exposure technology (or nanosphere lithography technology) on the photoresist A periodic micro-nano structure is formed on it, and a layer of gold film is sputtered (or evaporated) on it, and the gold film on the photoresist is removed by a lift-off process, while the gold in the gap of the photoresist micro-nano structure in contact with the titanium dioxide film is retained. thin film, thereby forming a gold sheet-like micro-nano structure, forming a gold-titanium d...

Embodiment 2

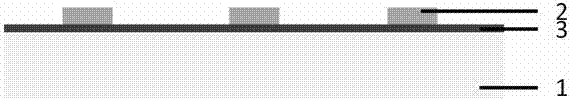

[0034] Such as figure 2As shown, the substrate 1 is glass, the semiconductor 2 is titanium dioxide, the metal 3 is gold, the metal 3 is evenly covered on the substrate 1, and the semiconductor 2 sheet-like micro-nano structure is on the metal 3 to form a metal-semiconductor composite micro-nano structure . The structure can be prepared by the following steps: uniformly deposit a layer of gold film on the glass substrate, spin-coat a layer of photoresist on it, and use multi-beam interference exposure technology (or nanosphere lithography technology) on the photoresist Form a periodic micro-nano structure on it, sputter (or evaporate) a layer of titanium dioxide film on it, use the stripping process to remove the titanium dioxide film on the photoresist, and keep the titanium dioxide in the gap of the photoresist micro-nano structure in contact with the gold film thin film, thereby forming a titanium dioxide flake micro-nano structure, and forming a gold-titania composite mic...

Embodiment 3

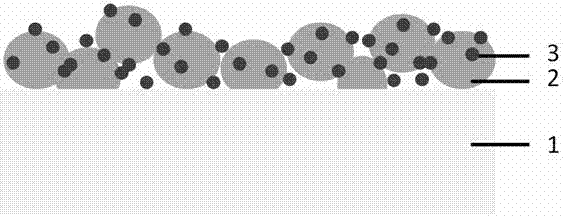

[0037] Such as image 3 As shown, the substrate 1 is silicon, the semiconductor 2 is titanium dioxide, the metal 3 is gold, the semiconductor 2 is nanospheres, and the metal 3 is nanospheres. structure. The structure can be prepared by the following steps: chemically synthesize gold nanospheres and titanium dioxide nanospheres, uniformly mix the two to form a suspension of gold nanospheres and titanium dioxide nanospheres, and spin coat, scrape, or spray the suspension Evenly distributed on the silicon substrate, after drying, a gold-titanium dioxide composite micro-nano structure can be formed.

[0038] Those skilled in the art can modify and adjust on the basis of Embodiment 3, for example, the substrate 1 can be replaced by transparent flexible substrates such as polyethylene terephthalate (PET) plastics, transparent rigid substrates such as glass, or It can be replaced by flexible and rigid substrates with micro-nano structures on the surface. Semiconductor 2 can be repl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com