High-catalytic activity probe material and preparation method and application thereof

A high catalytic activity and catalytic technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problem of less application of negative electrode materials, achieve controllable reaction components, improve electrical conductivity, and controllable experimental operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the highly catalytically active probe material of the present invention includes pretreatment and preparation steps, specifically including:

[0030] A. Pre-processing:

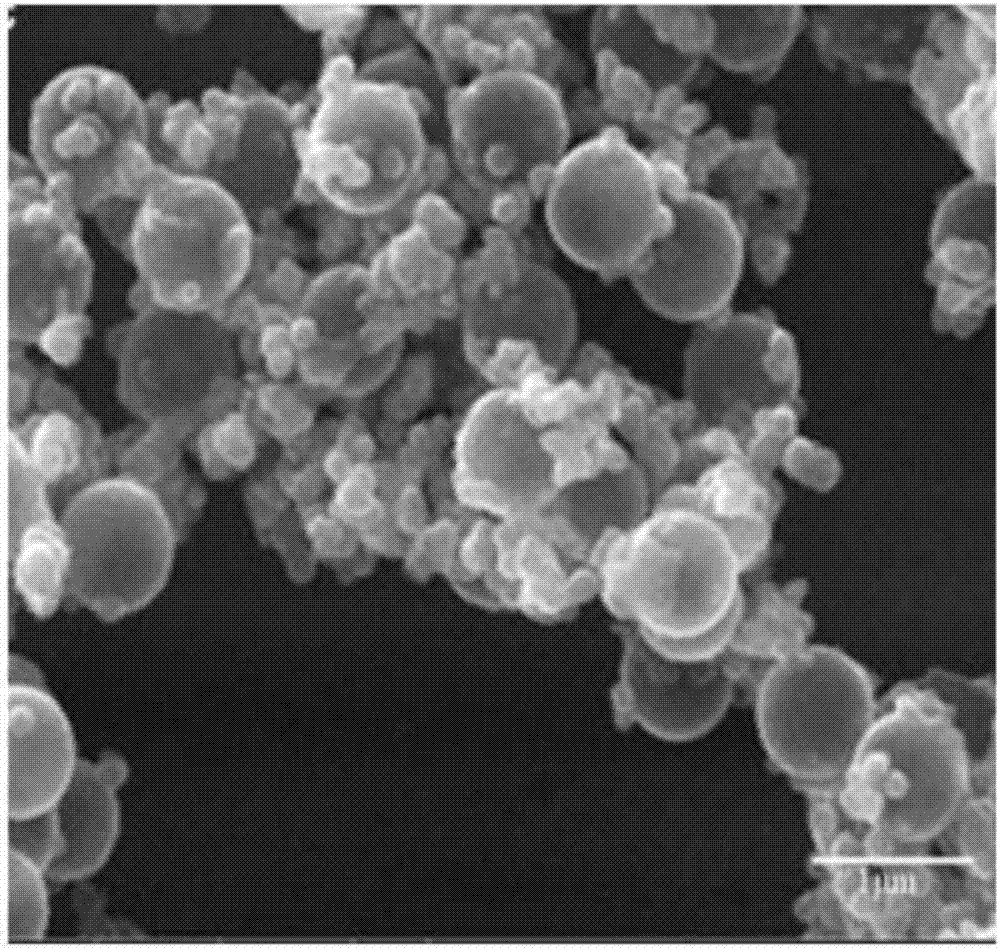

[0031] 1) Preparation of tin dioxide powder: add 5-70 parts by weight of tin chloride powder and 1-5 parts by weight of surfactant into 60-450 parts by weight of water, stir for 20-40 minutes, add weight Mix 12-120 parts of peroxide, react at constant temperature and equal volume at 150-220°C for 3-5 hours, centrifuge, wash, and dry to obtain black nano-tin dioxide powder;

[0032] 2) Preparation of rare earth hydrochloric acid solution: adding 1 to 10 parts by weight of rare earth oxides into the concentrated acid, stirring at a constant speed of 3000 r / min for 60 to 120 minutes to obtain a rare earth hydrochloric acid solution with a concentration of 0.05 to 0.7% by mass;

[0033] B. Preparation: Evenly disperse the black nano-tin dioxide powder obtained in step A into the ...

Embodiment 1

[0042] Add 20 g of tin chloride powder and 3 g of sodium dodecylbenzenesulfonate to 250 g of water. Stir for 30 minutes, add 80g of sodium peroxide and mix and transfer to the reactor (the inner lining in the still is polytetrafluoroethylene), stir and mix evenly. Reaction was carried out at constant temperature and equal volume at 200°C for 3 hours. After the reaction is finished, the product in the kettle is centrifuged, and the obtained precipitate is continuously washed by centrifugation, and dried to obtain nano-tin dioxide powder. Add the powder to Ce(NO 3 ) 3 ·6H 2 O solution, ultrasonically dispersed for 2 hours, aged at room temperature for 6 hours, and dried by rotary evaporation to finally obtain rare earth co-doped tin dioxide powder.

Embodiment 2

[0044] 50 g of tin chloride powder and 5 g of sodium dodecylbenzenesulfonate were added to 350 g of water. Stir for 30 minutes, add 100g of sodium peroxide and mix and transfer to the reaction kettle (the inner lining in the kettle is polytetrafluoroethylene), stir and mix evenly. React at constant temperature and equal volume for 4 hours at 150°C. After the reaction is finished, the product in the kettle is centrifuged, and the obtained precipitate is continuously washed by centrifugation, and after drying, the nano-tin dioxide powder can be obtained. Add the powder to La(NO 3 ) 3 ·6H 2 O solution, ultrasonically dispersed for 1 h, aged at room temperature for 3 h, and dried by rotary evaporation to finally obtain rare earth co-doped tin dioxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com