Preparation method of eggshell catalyst

A technology of eggshell-type catalysts and active components, applied in chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of low utilization rate of catalyst active components, low catalyst efficiency, precious metal To avoid agglomeration and sintering, to facilitate operation and to improve utilization rate due to problems such as large usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

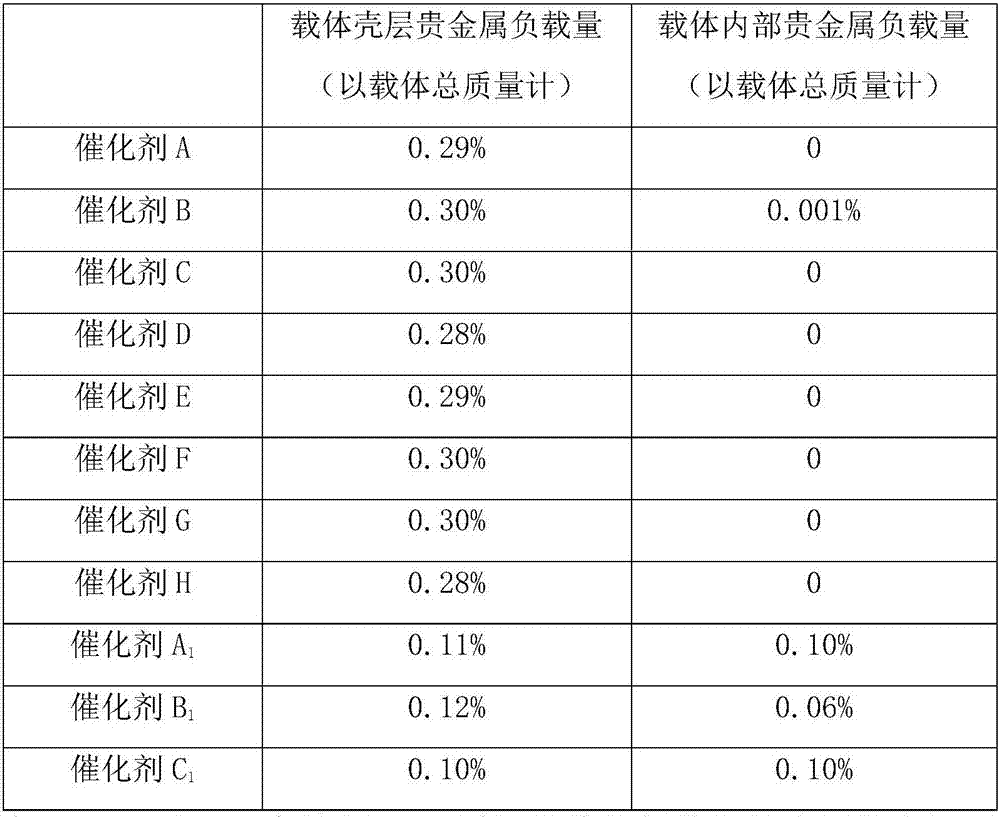

Embodiment 1

[0030] The preparation method of the eggshell catalyst provided by the present embodiment comprises the following steps:

[0031] Prepare a palladium nitrate aqueous solution with a mass percentage of 10%, then add the above-mentioned palladium nitrate aqueous solution to the glue solution, the mass ratio of the palladium nitrate aqueous solution to the glue solution is 1:9, and mix evenly to obtain the metal active Component precursor solution; The glue solution is SiO by mass ratio 2 :Al 2 o 3 : TiO 2 : Tianqing gum: Sodium carboxymethyl cellulose: Water = 10:0.1:10:0.1:0.1:100 The ratio is prepared after mixing evenly;

[0032] Using the metal active component precursor solution to impregnate α-Al 2 o 3 Spherical carrier, in this example, 50g spherical carrier requires 200mL metal active component precursor solution, impregnated 4 times, each time 1h, dried naturally, dried at 80°C for 2.5h, then calcined at 400°C for 3h , to obtain catalyst A.

Embodiment 2

[0034] The preparation method of the eggshell catalyst provided by the present embodiment comprises the following steps:

[0035]Prepare a ruthenium chloride aqueous solution with a mass percentage content of 3%, and then add the above-mentioned ruthenium chloride aqueous solution to the glue solution, the mass ratio of the ruthenium chloride aqueous solution to the glue solution is 1:2, and mix evenly, that is Obtain metal active component precursor solution; Described glue is to be SiO by mass ratio 2 :Al 2 o 3 : TiO 2 : Tianqing gum: sodium carboxymethyl cellulose: water = 0.1: 10: 0.1: 0.1: 1: 100 is prepared by mixing evenly;

[0036] Using the metal active component precursor solution to impregnate δ-Al 2 o 3 Spherical carrier, in this example, 50g spherical carrier needs 500mL metal active component precursor solution, impregnated 3 times, the time of each immersion is 1.5h, dry naturally, after drying at 50°C for 3h, calcined at 300°C 2h, catalyst B was obtained....

Embodiment 3

[0038] The preparation method of the eggshell catalyst provided by the present embodiment comprises the following steps:

[0039] Prepare a rhodium chloride aqueous solution with a mass percentage content of 20%, then add the above-mentioned rhodium chloride aqueous solution to the glue, the mass ratio of the rhodium chloride aqueous solution to the glue is 1:19.5, mix evenly, that is Obtain metal active component precursor solution; Described glue is to be SiO by mass ratio 2 :Al 2 o 3 : TiO 2 : Tianqing gum: Sodium carboxymethyl cellulose: Water = 0.1:1:1:0.1:0.2:100 The ratio is prepared after mixing evenly;

[0040] Using the metal active component precursor solution to impregnate θ-Al 2 o 3 Spherical carrier, in this example, 50g spherical carrier needs 300mL metal active component precursor solution, impregnated 5 times, the time of each immersion is 0.5h, dried naturally, dried at 120°C for 2h, then calcined at 500°C for 4h , to obtain catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com