Macroscopic-quantity preparation method of phosphorene

A phosphorene and macro-scale technology, applied in the field of macro-scale preparation of phosphorene, can solve the problems of difficulty in obtaining large-scale phosphorene, difficulty in large-scale production, complicated operations, etc., and achieves good peeling effect, high equipment utilization, The effect of easy automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

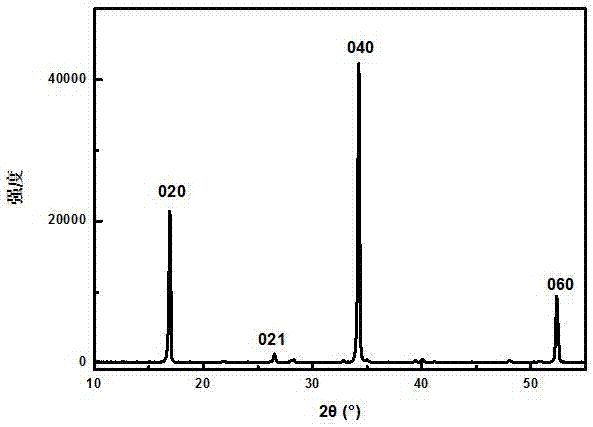

[0022] (1) Weigh 0.2g of orthorhombic black phosphorus crystal with a balance (XRD pattern as figure 1 shown) into the reagent bottle, then use a graduated cylinder to measure 200mL of organic solvent NMP (N-methylpyrrolidone) and pour it into the reagent bottle, and mix well to obtain a mixed solution after sealing;

[0023] (2) Evacuate the air in the high-pressure homogenizer with argon, pour the mixed liquid prepared in step (1) into the hopper of the high-pressure homogenizer, turn on the power, turn on the high-pressure homogenizer, and set the working pressure to 1500bar, make the mixed liquid pass through the homogenization chamber of the high-pressure homogenizer at high speed, and obtain a suspension with good peeling effect after 5 minutes;

[0024] (3) Centrifuge the suspension obtained in step (2) at a rotational speed of 2000 rpm, filter the supernatant with a polytetrafluoroethylene membrane, and wash repeatedly with deionized water and absolute ethanol to obtai...

Embodiment 2

[0027] (1) Weigh 2g of orthorhombic black phosphorus crystals with a balance (XRD pattern as figure 1 shown) into the reagent bottle, then use a graduated cylinder to measure 200mL of ionic liquid 1-butyl-3-methylimidazolium hexafluorophosphate, pour it into the reagent bottle, and mix evenly to obtain a mixed solution after sealing;

[0028] (2) Evacuate the air in the high-pressure homogenizer with helium, pour the mixed solution prepared in step (1) into the hopper of the high-pressure homogenizer, turn on the power, turn on the high-pressure homogenizer, and set the working pressure to 1600bar, make the mixed liquid pass through the homogenization chamber of the high-pressure homogenizer at high speed, and obtain a suspension with good peeling effect after 30 minutes;

[0029] (3) Centrifuge the suspension obtained in step (2) at a rotational speed of 4000 rpm, filter the supernatant with a polypropylene membrane, and wash repeatedly with deionized water and absolute ethan...

Embodiment 3

[0031] (1) Weigh 10g of orthorhombic black phosphorus crystals with a balance (XRD pattern as figure 1 shown) into the reagent bottle, then use a measuring cylinder to measure 200mL deionized water into the reagent bottle, and mix well after sealing;

[0032] (2) Evacuate the air in the high-pressure homogenizer with nitrogen, pour the prepared mixed solution into the hopper of the high-pressure homogenizer, turn on the power, turn on the high-pressure homogenizer, set the working pressure to 1700bar, and make the mixed solution Pass through the homogenization chamber of the high-pressure homogenizer at high speed, and obtain a suspension with good peeling effect after 60 minutes;

[0033] (3) Centrifuge the suspension obtained in step (2) at a rotational speed of 8000 rpm, filter the supernatant with a nitrocellulose membrane, and wash repeatedly with deionized water and absolute ethanol to obtain phosphorene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com