Wastewater zero discharge treatment system for scr catalyst regeneration wastewater

A technology of SCR catalyst and regenerated waste water, which is applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. It can solve problems such as failure to meet discharge requirements, high treatment costs, and residual heavy metals, and achieve Excellent wastewater treatment effect, increase water return rate, and reduce sludge discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

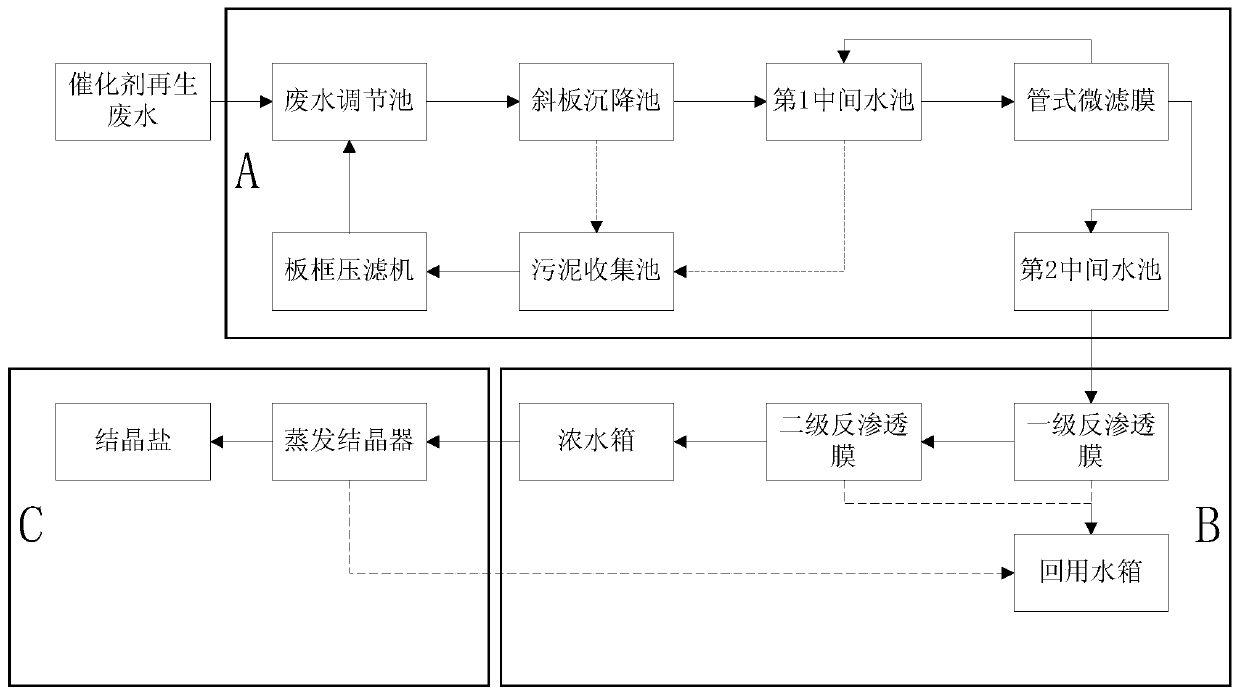

[0021] As shown in the figure, the waste water zero-discharge treatment system of the SCR catalyst regenerated waste water of the present embodiment, the waste water zero-discharge treatment system of the SCR catalyst regenerated waste water includes a pretreatment system A, a membrane concentration system B and an evaporation system C; the regenerated waste water is passed through After the pretreatment system A removes suspended solids in the water through multiple cycles, the membrane concentration system B is used for concentration treatment, the fresh water obtained from the concentration treatment is collected, and the concentrated water obtained from the concentration treatment flows into the evaporation system C for evaporation treatment; The method of multiple circulation treatment fully separates the liquid and solid suspended matter in the wastewater, and then the liquid is subjected to membrane concentration treatment and evaporation treatment, and the final treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com