Method for producing organic fertilizer by reutilizing liquid pig manure

A technology of organic fertilizer and pig manure, which is applied to the preparation of organic fertilizer, organic fertilizer, fertilizer made from biological waste, etc., to achieve the effects of increasing added value, protecting the ecological environment, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] acquisition of raw materials

[0024] The pig manure water for the test was taken from a Suhuai pig farm in Huai’an, and the mushroom slag, rice bran and sawdust were all taken from Huai’an City, Jiangsu Province. The basic properties are shown in Table 1. The experimental site is Jiangsu Junde Ecological Agriculture Science and Technology Co., Ltd. Ltd composting workshop.

[0025] Table 1 Basic properties of raw materials

[0026]

[0027] implementation details

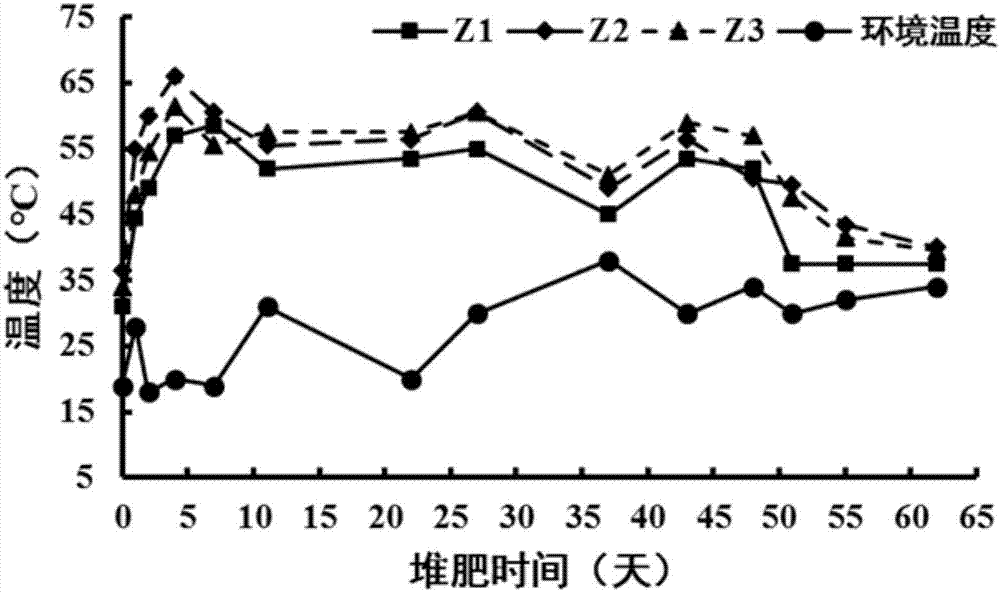

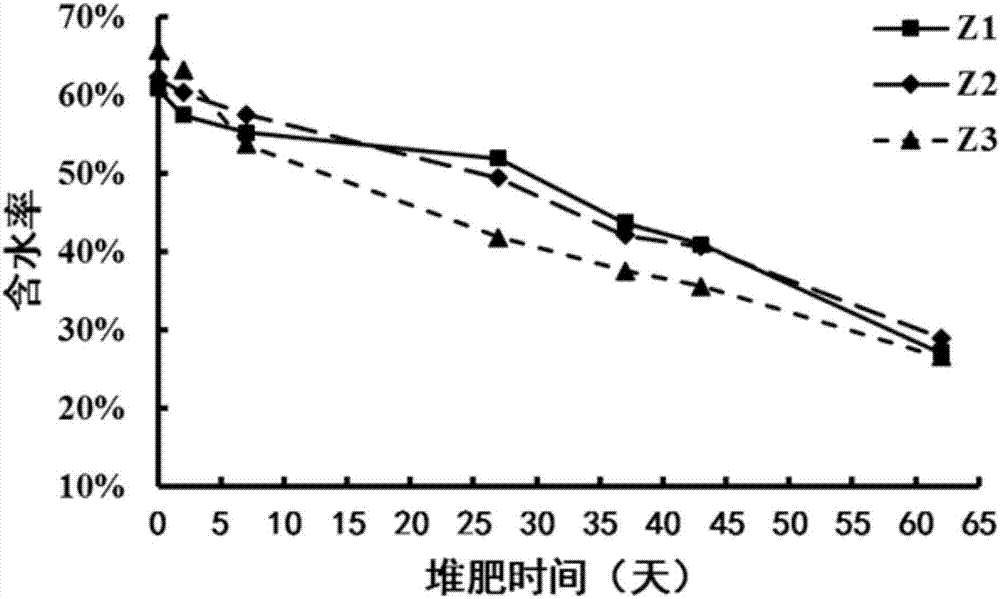

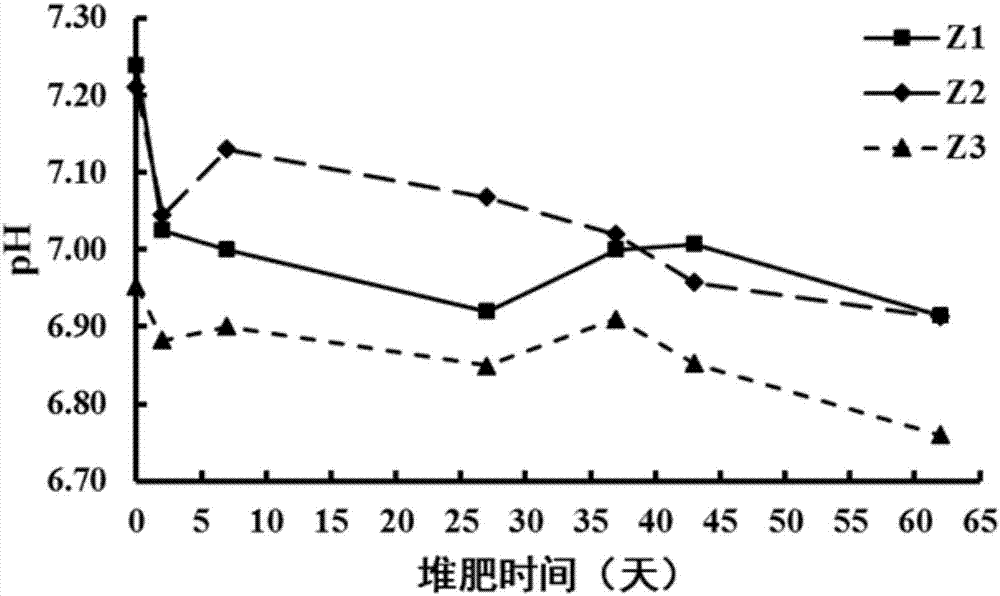

[0028] Mushroom slag (3 tons, wet weight), hulled chaff (1 ton, wet weight) and sawdust (1.5 tons, wet weight) are preliminarily mixed, and then stacked into a pile of strips, and the top of the pile is dug. Set up 3 treatments, add 0.5 tons (Z1), 1 ton (Z2) and 2 tons (Z3) of pig manure water on the 0th, 5th, 12th, 19th, 30th, 38th, and 56th days, and turn over every 3 days Throwing machine (LYFP280A produced by Jiangyin Lianye Biotechnology Co., Ltd.) was turned over, and samples were taken on days 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com