High-stain-resistant antibacterial modified antirust agent

A technology of anti-rust agent and modification, which is applied in the field of anti-rust agent and can solve the problems of accelerating metal, increasing cost, and rusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

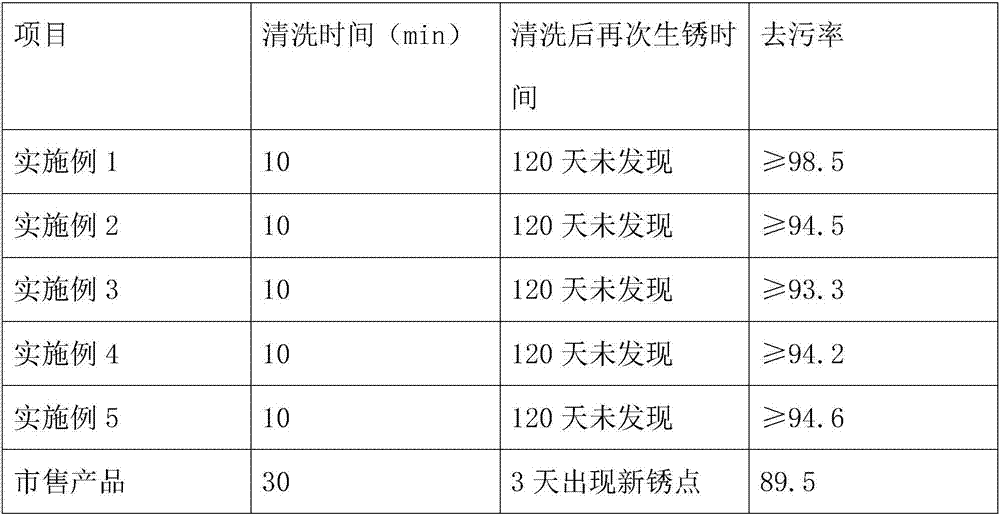

Examples

Embodiment 1

[0016] A kind of antifouling antibacterial modified antirust agent proposed by the present invention, its raw material comprises by weight: 15 parts of phosphoric acid, 6 parts of polyethylene glycol, 6 parts of zinc naphthenate, 6 parts of amine-soluble quaternary ammonium copper, six parts 2 parts of sodium metaphosphate, 4 parts of nano silicon dioxide, 6 parts of sodium sulfonate, 6 parts of dodecenyl succinic acid, 6 parts of petrolatum, 3.5 parts of benzotriazole, 3.5 parts of sodium alkenyl sulfonate, 4.5 parts of sodium tripolyphosphate, 2.5 parts of sodium metasilicate, 3.5 parts of sodium nitrite, 4.5 parts of diamine hydrogen phosphate, 2.5 parts of triethanolamine, 6 parts of antioxidant antibacterial agent, 3.5 parts of stain resistance enhancer, antibacterial enhancer 6 parts, degreasing agent 6 parts, deionized water 20 parts.

[0017] The antioxidant antibacterial agent is prepared according to the following process: 3.5 parts of tea polyphenols, 2 parts of ace...

Embodiment 2

[0022] A kind of antifouling antibacterial modified antirust agent proposed by the present invention, its raw material comprises by weight: 10 parts of phosphoric acid, 8 parts of polyethylene glycol, 4 parts of zinc naphthenate, 8 parts of amine-soluble quaternary ammonium copper, six parts 1 part of sodium metaphosphate, 6 parts of nano silicon dioxide, 3 parts of sodium sulfonate, 8 parts of dodecenyl succinic acid, 4 parts of petrolatum, 5 parts of benzotriazole, 1 part of sodium alkenyl sulfonate, 6 parts of sodium tripolyphosphate, 1 part of sodium metasilicate, 5 parts of sodium nitrite, 3 parts of diamine hydrogen phosphate, 4 parts of triethanolamine, 4 parts of antioxidant antibacterial agent, 5 parts of stain resistance enhancer, antibacterial enhancer 4 parts, 8 parts degreaser, 15 parts deionized water.

[0023] The antioxidant antibacterial agent is prepared according to the following process: mix 2 parts of tea polyphenols, 3 parts of acetic anhydride, 0.5 parts...

Embodiment 3

[0028] A kind of antifouling antibacterial modified antirust agent proposed by the present invention, its raw material comprises by weight: 20 parts of phosphoric acid, 4 parts of polyethylene glycol, 8 parts of zinc naphthenate, 4 parts of amine-soluble quaternary ammonium copper, six parts 3 parts of sodium metaphosphate, 2 parts of nano silicon dioxide, 9 parts of sodium sulfonate, 4 parts of dodecenyl succinic acid, 8 parts of petrolatum, 2 parts of benzotriazole, 6 parts of sodium alkenyl sulfonate, 3 parts of sodium tripolyphosphate, 4 parts of sodium metasilicate, 2 parts of sodium nitrite, 6 parts of diamine hydrogen phosphate, 1 part of triethanolamine, 8 parts of antioxidant antibacterial agent, 2 parts of stain resistance enhancer, antibacterial enhancer 8 parts, 4 parts of degreaser, 25 parts of deionized water.

[0029] Antioxidant antibacterial agent is prepared according to the following process: mix 5 parts of tea polyphenols, 1 part of acetic anhydride, 1.5 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com